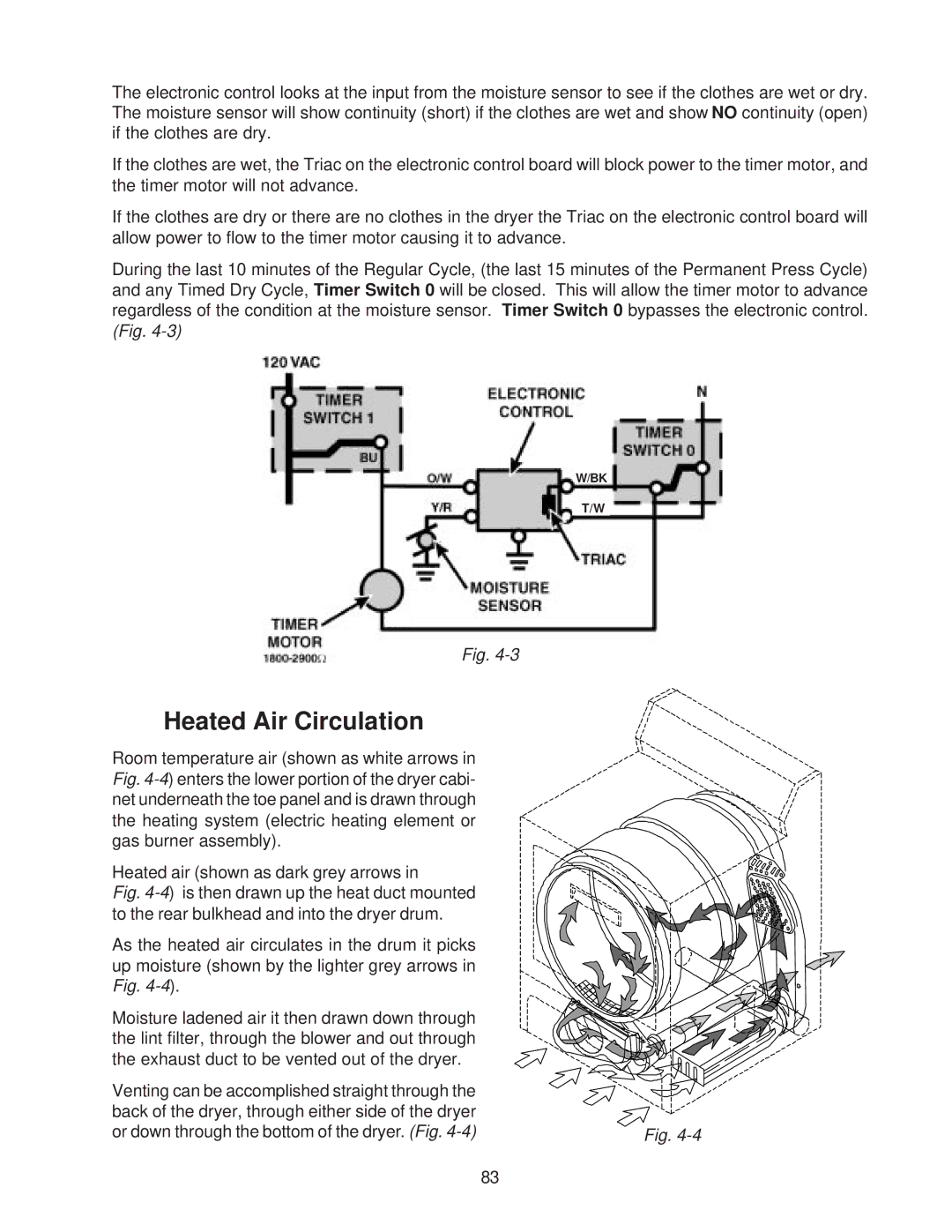

The electronic control looks at the input from the moisture sensor to see if the clothes are wet or dry. The moisture sensor will show continuity (short) if the clothes are wet and show NO continuity (open) if the clothes are dry.

If the clothes are wet, the Triac on the electronic control board will block power to the timer motor, and the timer motor will not advance.

If the clothes are dry or there are no clothes in the dryer the Triac on the electronic control board will allow power to flow to the timer motor causing it to advance.

During the last 10 minutes of the Regular Cycle, (the last 15 minutes of the Permanent Press Cycle) and any Timed Dry Cycle, Timer Switch 0 will be closed. This will allow the timer motor to advance regardless of the condition at the moisture sensor. Timer Switch 0 bypasses the electronic control. (Fig.

Fig.

Heated Air Circulation

Room temperature air (shown as white arrows in Fig.

Heated air (shown as dark grey arrows in

Fig. 4-4) is then drawn up the heat duct mounted to the rear bulkhead and into the dryer drum.

As the heated air circulates in the drum it picks up moisture (shown by the lighter grey arrows in Fig. 4-4).

Moisture ladened air it then drawn down through the lint filter, through the blower and out through the exhaust duct to be vented out of the dryer.

Venting can be accomplished straight through the back of the dryer, through either side of the dryer or down through the bottom of the dryer. (Fig.

W/BK

T/W

Fig.

83