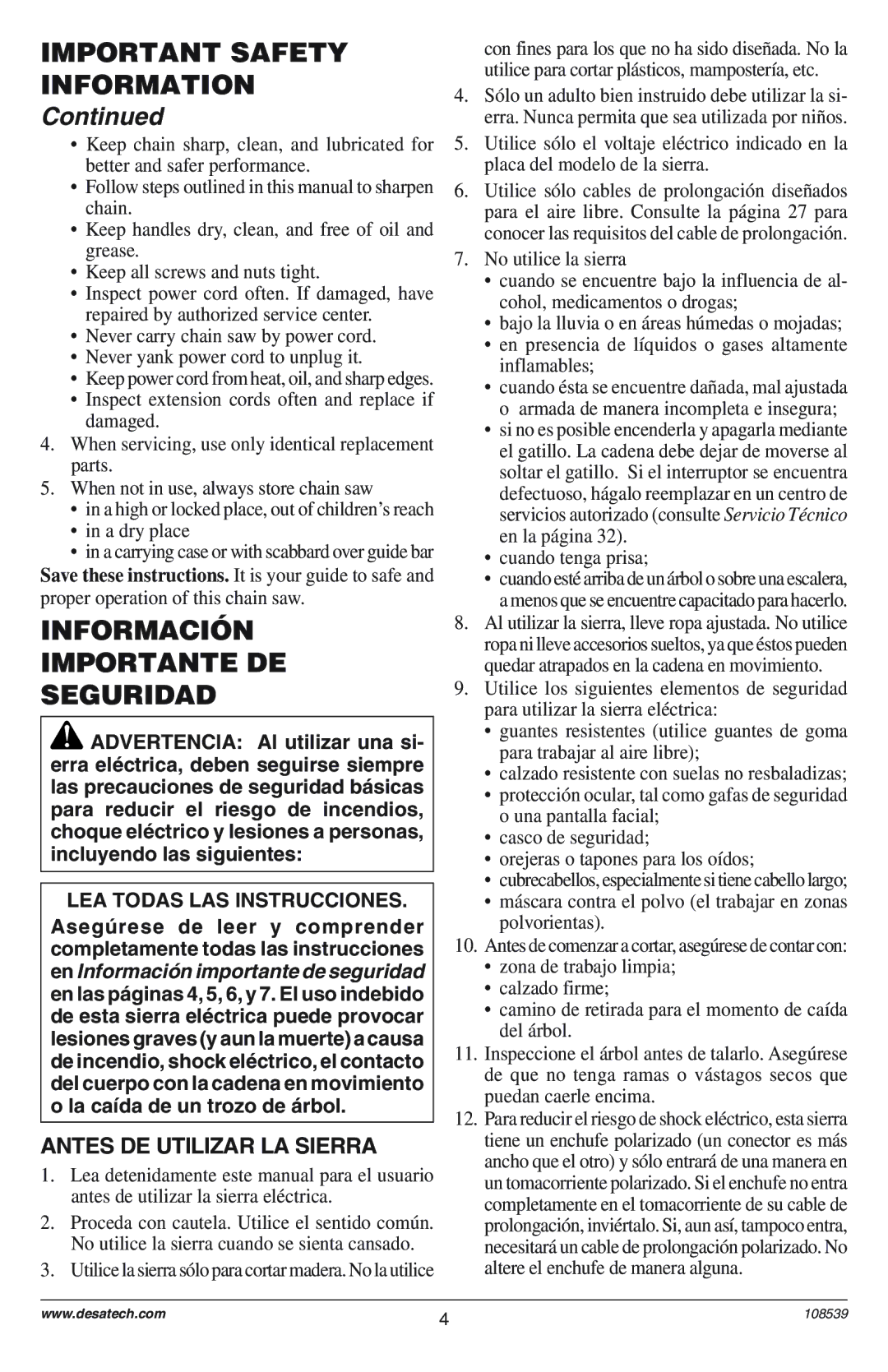

CHAIN SAW NAMES AND TERMS

Continued

Replacement Chain Chain that complies with ANSI B175.1 when used with a speciÞc saw. It may not meet ANSI requirements when used with other saws. Saw Chain (Chain) Loop of chain having cutting teeth for cutting wood. The motor drives chain. The guide bar supports chain.

Spiked Bumper (Spike) Pointed teeth at front of saw body beside guide bar. Keep spiked bumper in contact with wood when felling or bucking. It helps maintain position of saw while cutting.

Sprocket Toothed wheel that drives chain. Switch Device that completes or interrupts electri- cal circuit to motor of saw.

Switch Linkage This device connects switch to trig- ger. It moves switch when you squeeze trigger. Switch Lockout Device that reduces accidental start- ing of saw.

Trigger Device that turns saw on and off. Squeezing trigger turns saw on. Releasing trigger turns saw off. Trimming (Pruning) Process of cutting limb(s) from a living tree.

Undercut An upward cut from underside of log or limb. This is done while in normal cutting position and cutting with top of guide bar.

ASSEMBLY

Note: Some models are

See Saw Chain Tension Adjustment, pages 16 and 17.

![]() WARNING: Cutting edges on chain are sharp. Use protective gloves when handling chain.

WARNING: Cutting edges on chain are sharp. Use protective gloves when handling chain.

IMPORTANT: Do not clamp chain saw in vise during assembly.

The plastic hardware bag should include:

¥two guide bar bolts

¥two guide bar nuts

¥one

¥automatic chain sharpener (Fast Sharp models only)

1.Lay chain out ßat.

2.Install front hand guard onto saw body. Do this by pressing two mounting

3Insert tapping screw through hand guard and into saw handle. Tighten screw Þrmly.

4.Turn adjusting screw counterclockwise (see Fig- ure 4). Continue to turn adjusting screw until adjusting block is to rear of adjusting plate.

5.Install guide bar onto saw body. Place rear of guide bar between adjusting plate and sprocket support.

IMPORTANT: Make sure to insert adjusting block into oval adjusting hole on guide bar.

6.Line up holes on sprocket support with center slot on guide bar and holes in saw body.

7.Insert guide bar bolts through front hand guard, saw body, center slot of guide bar, and sprocket support. Attach guide bar nuts to guide bar bolts. IMPORTANT: Tighten guide bar nuts Þnger tight only. Make sure adjusting block is in oval adjusting hole on guide bar.

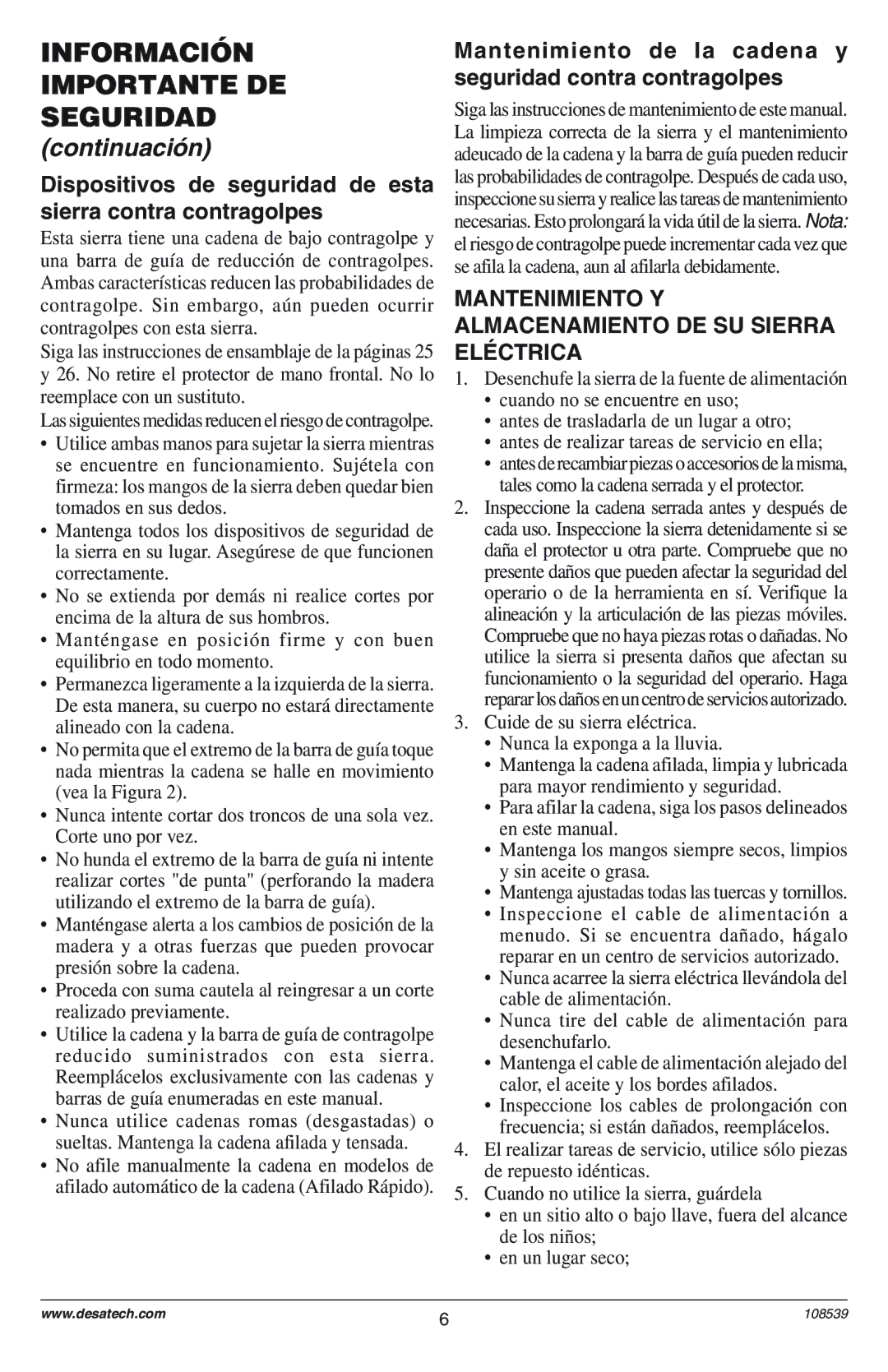

8.Place chain around drive sprocket, then along top groove of guide bar and around guide bar nose. Note: Make sure cutting edges of chain are fac- ing the right direction. Position chain so cutting edges on top of guide bar face guide bar nose (see Figure 3).

![]() CAUTION: Do not place chain on saw backwards. If chain is backwards, saw will vibrate badly and will not cut.

CAUTION: Do not place chain on saw backwards. If chain is backwards, saw will vibrate badly and will not cut.

9.Adjust saw chain tension. Follow steps under Saw Chain Tension Adjustment, pages 16 and 17.

SAW CHAIN TENSION ADJUSTMENT

![]() WARNING: Unplug chain saw from power source before adjusting saw chain tension.

WARNING: Unplug chain saw from power source before adjusting saw chain tension.

![]() WARNING: Cutting edges on chain are sharp. Use protective gloves when handling chain.

WARNING: Cutting edges on chain are sharp. Use protective gloves when handling chain.

![]() WARNING: Maintain proper chain tension always. A loose chain will in- crease the risk of kickback. A loose chain may jump out of guide bar groove. This may injure operator and damage chain. A loose chain will cause chain, guide bar, and sprocket to wear rapidly.

WARNING: Maintain proper chain tension always. A loose chain will in- crease the risk of kickback. A loose chain may jump out of guide bar groove. This may injure operator and damage chain. A loose chain will cause chain, guide bar, and sprocket to wear rapidly.

Note: For

1.Before adjusting chain, make sure guide bar nuts are only Þnger tight (see Figure 3). Also make sure adjusting block is in oval adjusting hole on guide bar (see Figures 3 and 4).

www.desatech.com | 16 | 108539 |

|

|