cd660

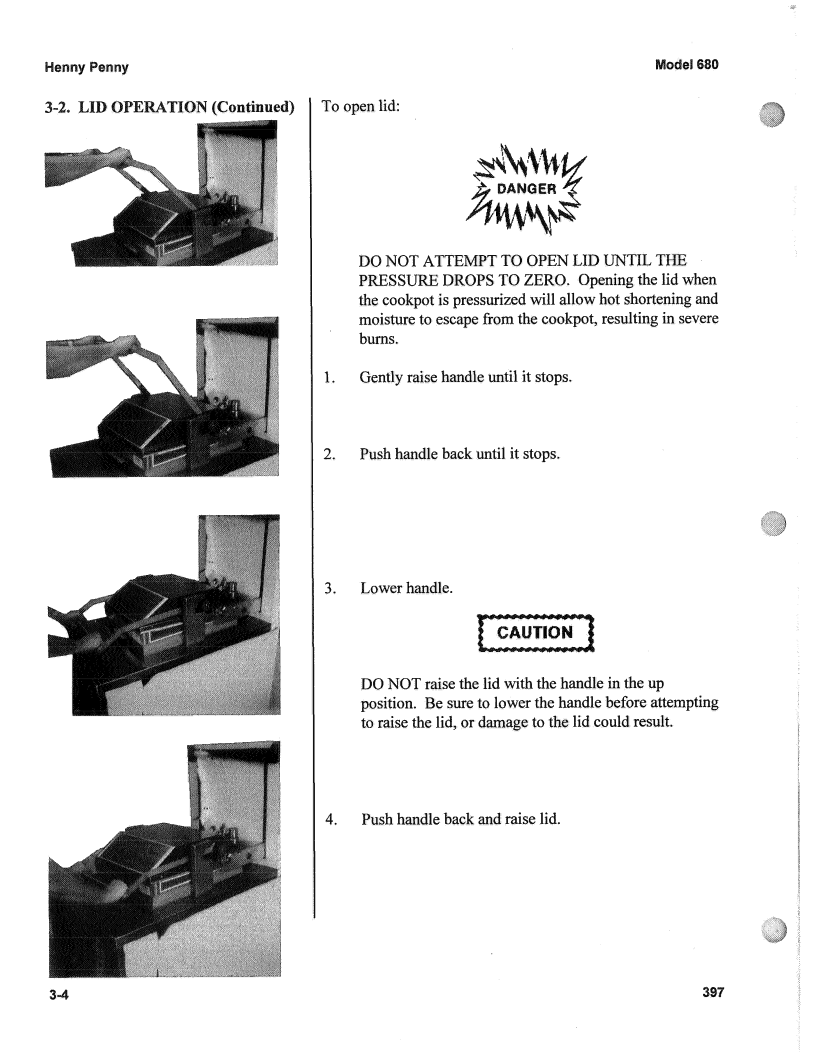

To open lid:

DO NOT ATTEMPT TO OPEN LID UNTIL THE PRESSURE DROPS TO ZERO. Opening the lid when the cookpot is pressurized will allow hot shortening and moisture to escape from the cookpot, resulting in severe burns.

1.Gently raise handle until it stops.

2.Push handle back until it stops.

3.Lower handle.

DO NOT raise the lid with the handle in the up position. Be sure to lower the handle before attempting to raise the lid, or damage to the lid could result.