CONNECTING AIR PRESSURE

Attach the shop air line to the robot at the air line hose con- nection. Air pressure should be 80 PSI working pressure and 100 PSI maximum pressure. Do not connect and turn on the air until AFTER setting the gripper position and strip move- ment.

ADJUSTING THE

SPRUE

VERIFICATION

SWITCH

To ensure proper part/sprue verification, adjust the

1 Press the Manual button

to place the robot in manual mode.

2 Press the Grip (On/Off) button

to cycle the gripper open and closed.

3

Place a sprue into the open gripper

jaws and press the Grip button to grip the sprue. The grip- per should grip the sprue enough to be able to lift it, but not deform or break it.

4

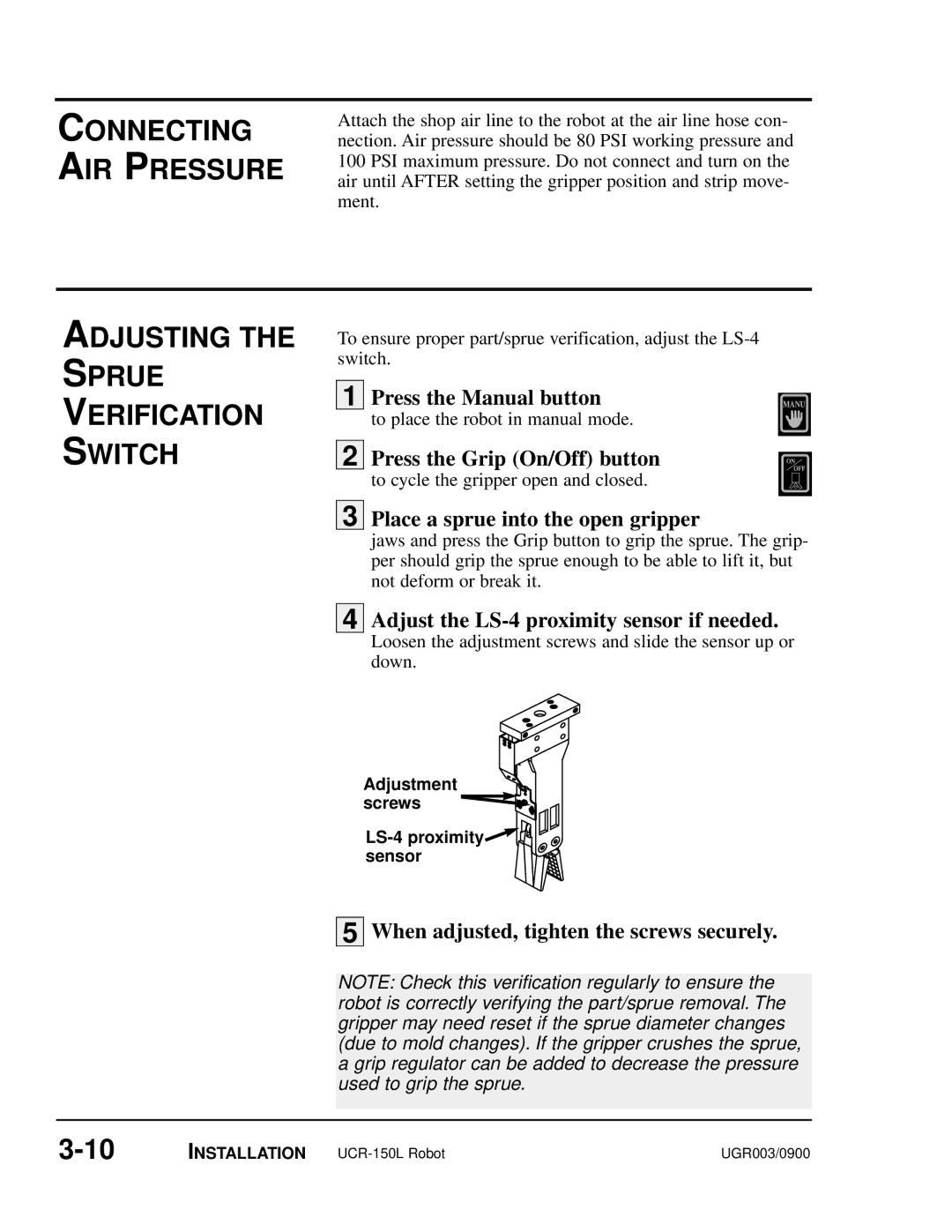

Adjust the LS-4 proximity sensor if needed.

Loosen the adjustment screws and slide the sensor up or down.

Adjustment screws

![]() sensor

sensor

5

When adjusted, tighten the screws securely.

NOTE: Check this verification regularly to ensure the robot is correctly verifying the part/sprue removal. The gripper may need reset if the sprue diameter changes (due to mold changes). If the gripper crushes the sprue, a grip regulator can be added to decrease the pressure used to grip the sprue.

INSTALLATION | UGR003/0900 |