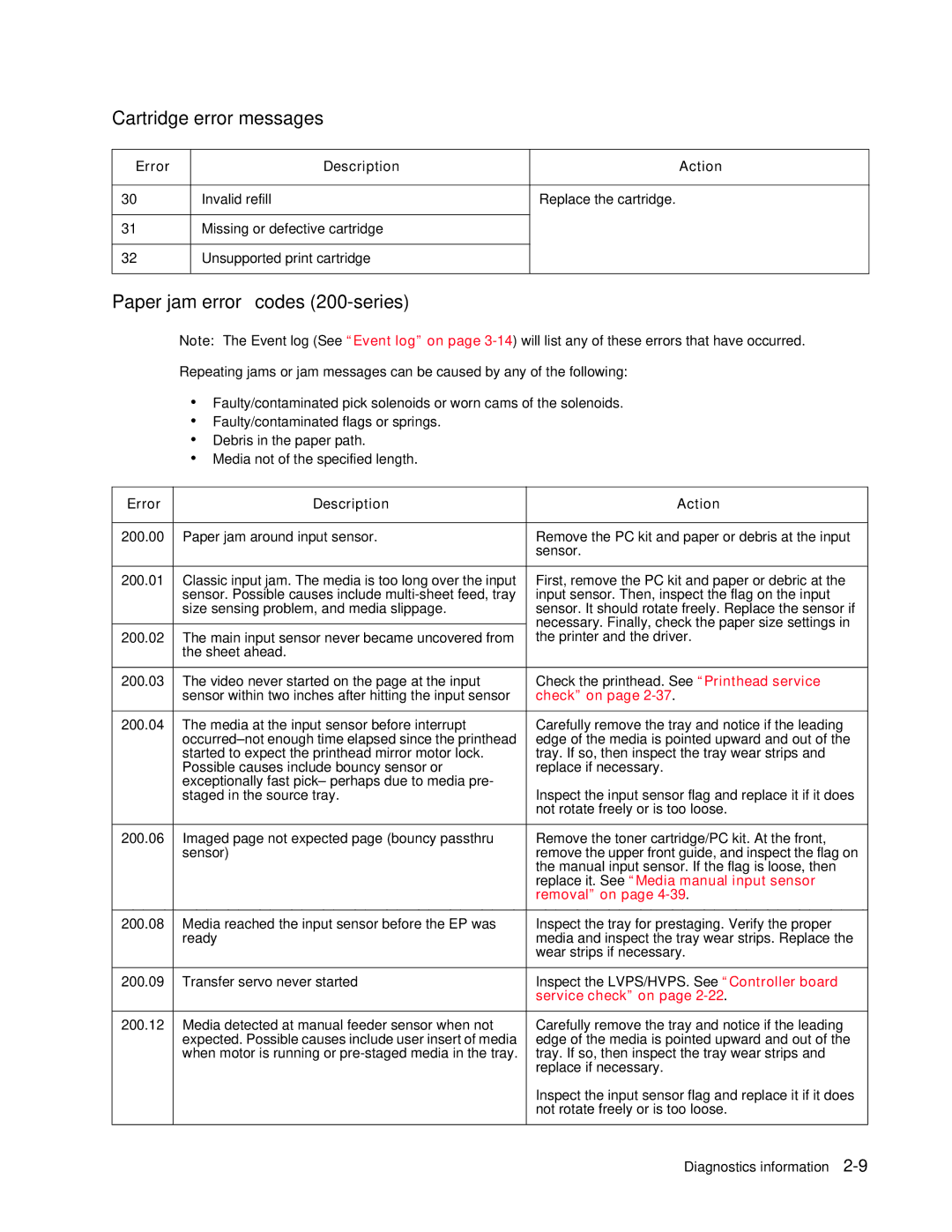

Cartridge error messages

Error |

| Description | Action |

|

|

|

|

30 | Invalid | refill | Replace the cartridge. |

|

|

|

|

31 | Missing | or defective cartridge |

|

|

|

| |

32 | Unsupported print cartridge |

| |

|

|

|

|

Paper jam error codes (200-series)

Note: The Event log (See “Event log” on page

Repeating jams or jam messages can be caused by any of the following:

•Faulty/contaminated pick solenoids or worn cams of the solenoids.

•Faulty/contaminated flags or springs.

•Debris in the paper path.

•Media not of the specified length.

Error | Description | Action |

|

|

|

200.00 | Paper jam around input sensor. | Remove the PC kit and paper or debris at the input |

|

| sensor. |

|

|

|

200.01 | Classic input jam. The media is too long over the input | First, remove the PC kit and paper or debric at the |

| sensor. Possible causes include | input sensor. Then, inspect the flag on the input |

| size sensing problem, and media slippage. | sensor. It should rotate freely. Replace the sensor if |

|

| necessary. Finally, check the paper size settings in |

|

| |

200.02 | The main input sensor never became uncovered from | the printer and the driver. |

| the sheet ahead. |

|

|

|

|

200.03 | The video never started on the page at the input | Check the printhead. See “Printhead service |

| sensor within two inches after hitting the input sensor | check” on page |

|

|

|

200.04 | The media at the input sensor before interrupt | Carefully remove the tray and notice if the leading |

| edge of the media is pointed upward and out of the | |

| started to expect the printhead mirror motor lock. | tray. If so, then inspect the tray wear strips and |

| Possible causes include bouncy sensor or | replace if necessary. |

| exceptionally fast pick– perhaps due to media pre- |

|

| staged in the source tray. | Inspect the input sensor flag and replace it if it does |

|

| not rotate freely or is too loose. |

|

|

|

200.06 | Imaged page not expected page (bouncy passthru | Remove the toner cartridge/PC kit. At the front, |

| sensor) | remove the upper front guide, and inspect the flag on |

|

| the manual input sensor. If the flag is loose, then |

|

| replace it. See “Media manual input sensor |

|

| removal” on page |

|

|

|

200.08 | Media reached the input sensor before the EP was | Inspect the tray for prestaging. Verify the proper |

| ready | media and inspect the tray wear strips. Replace the |

|

| wear strips if necessary. |

|

|

|

200.09 | Transfer servo never started | Inspect the LVPS/HVPS. See “Controller board |

|

| service check” on page |

|

|

|

200.12 | Media detected at manual feeder sensor when not | Carefully remove the tray and notice if the leading |

| expected. Possible causes include user insert of media | edge of the media is pointed upward and out of the |

| when motor is running or | tray. If so, then inspect the tray wear strips and |

|

| replace if necessary. |

|

| Inspect the input sensor flag and replace it if it does |

|

| not rotate freely or is too loose. |

|

|

|

Diagnostics information