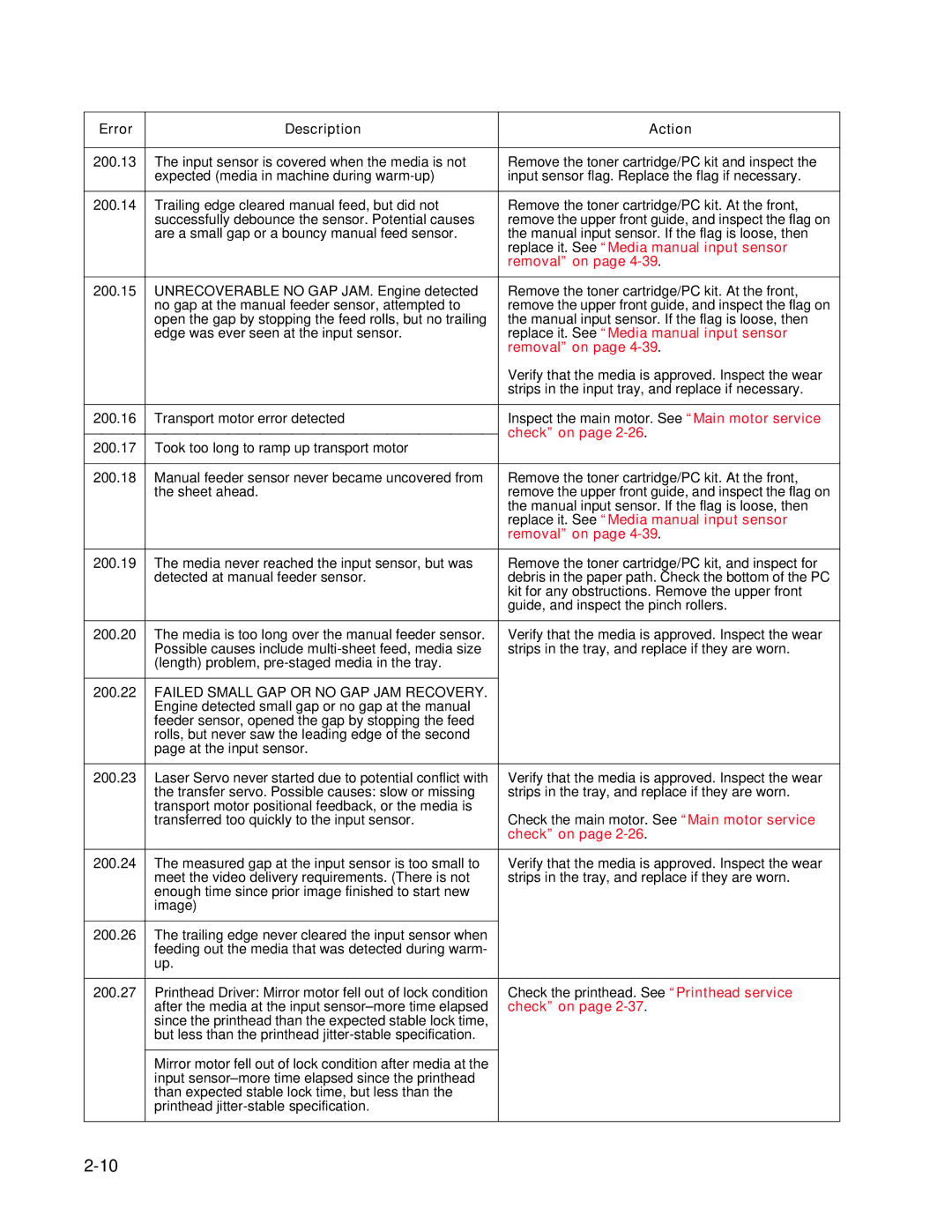

Error | Description | Action | |

|

|

| |

200.13 | The input sensor is covered when the media is not | Remove the toner cartridge/PC kit and inspect the | |

| expected (media in machine during | input sensor flag. Replace the flag if necessary. | |

|

|

| |

200.14 | Trailing edge cleared manual feed, but did not | Remove the toner cartridge/PC kit. At the front, | |

| successfully debounce the sensor. Potential causes | remove the upper front guide, and inspect the flag on | |

| are a small gap or a bouncy manual feed sensor. | the manual input sensor. If the flag is loose, then | |

|

| replace it. See “Media manual input sensor | |

|

| removal” on page | |

|

|

| |

200.15 | UNRECOVERABLE NO GAP JAM. Engine detected | Remove the toner cartridge/PC kit. At the front, | |

| no gap at the manual feeder sensor, attempted to | remove the upper front guide, and inspect the flag on | |

| open the gap by stopping the feed rolls, but no trailing | the manual input sensor. If the flag is loose, then | |

| edge was ever seen at the input sensor. | replace it. See “Media manual input sensor | |

|

| removal” on page | |

|

| Verify that the media is approved. Inspect the wear | |

|

| strips in the input tray, and replace if necessary. | |

|

|

| |

200.16 | Transport motor error detected | Inspect the main motor. See “Main motor service | |

|

| check” on page | |

200.17 | Took too long to ramp up transport motor | ||

| |||

|

|

| |

200.18 | Manual feeder sensor never became uncovered from | Remove the toner cartridge/PC kit. At the front, | |

| the sheet ahead. | remove the upper front guide, and inspect the flag on | |

|

| the manual input sensor. If the flag is loose, then | |

|

| replace it. See “Media manual input sensor | |

|

| removal” on page | |

|

|

| |

200.19 | The media never reached the input sensor, but was | Remove the toner cartridge/PC kit, and inspect for | |

| detected at manual feeder sensor. | debris in the paper path. Check the bottom of the PC | |

|

| kit for any obstructions. Remove the upper front | |

|

| guide, and inspect the pinch rollers. | |

|

|

| |

200.20 | The media is too long over the manual feeder sensor. | Verify that the media is approved. Inspect the wear | |

| Possible causes include | strips in the tray, and replace if they are worn. | |

| (length) problem, |

| |

|

|

| |

200.22 | FAILED SMALL GAP OR NO GAP JAM RECOVERY. |

| |

| Engine detected small gap or no gap at the manual |

| |

| feeder sensor, opened the gap by stopping the feed |

| |

| rolls, but never saw the leading edge of the second |

| |

| page at the input sensor. |

| |

|

|

| |

200.23 | Laser Servo never started due to potential conflict with | Verify that the media is approved. Inspect the wear | |

| the transfer servo. Possible causes: slow or missing | strips in the tray, and replace if they are worn. | |

| transport motor positional feedback, or the media is | Check the main motor. See “Main motor service | |

| transferred too quickly to the input sensor. | ||

|

| check” on page | |

|

|

| |

200.24 | The measured gap at the input sensor is too small to | Verify that the media is approved. Inspect the wear | |

| meet the video delivery requirements. (There is not | strips in the tray, and replace if they are worn. | |

| enough time since prior image finished to start new |

| |

| image) |

| |

|

|

| |

200.26 | The trailing edge never cleared the input sensor when |

| |

| feeding out the media that was detected during warm- |

| |

| up. |

| |

|

|

| |

200.27 | Printhead Driver: Mirror motor fell out of lock condition | Check the printhead. See “Printhead service | |

| after the media at the input | check” on page | |

| since the printhead than the expected stable lock time, |

| |

| but less than the printhead |

| |

|

|

| |

| Mirror motor fell out of lock condition after media at the |

| |

| input |

| |

| than expected stable lock time, but less than the |

| |

| printhead |

| |

|

|

|

Page 36

Image 36