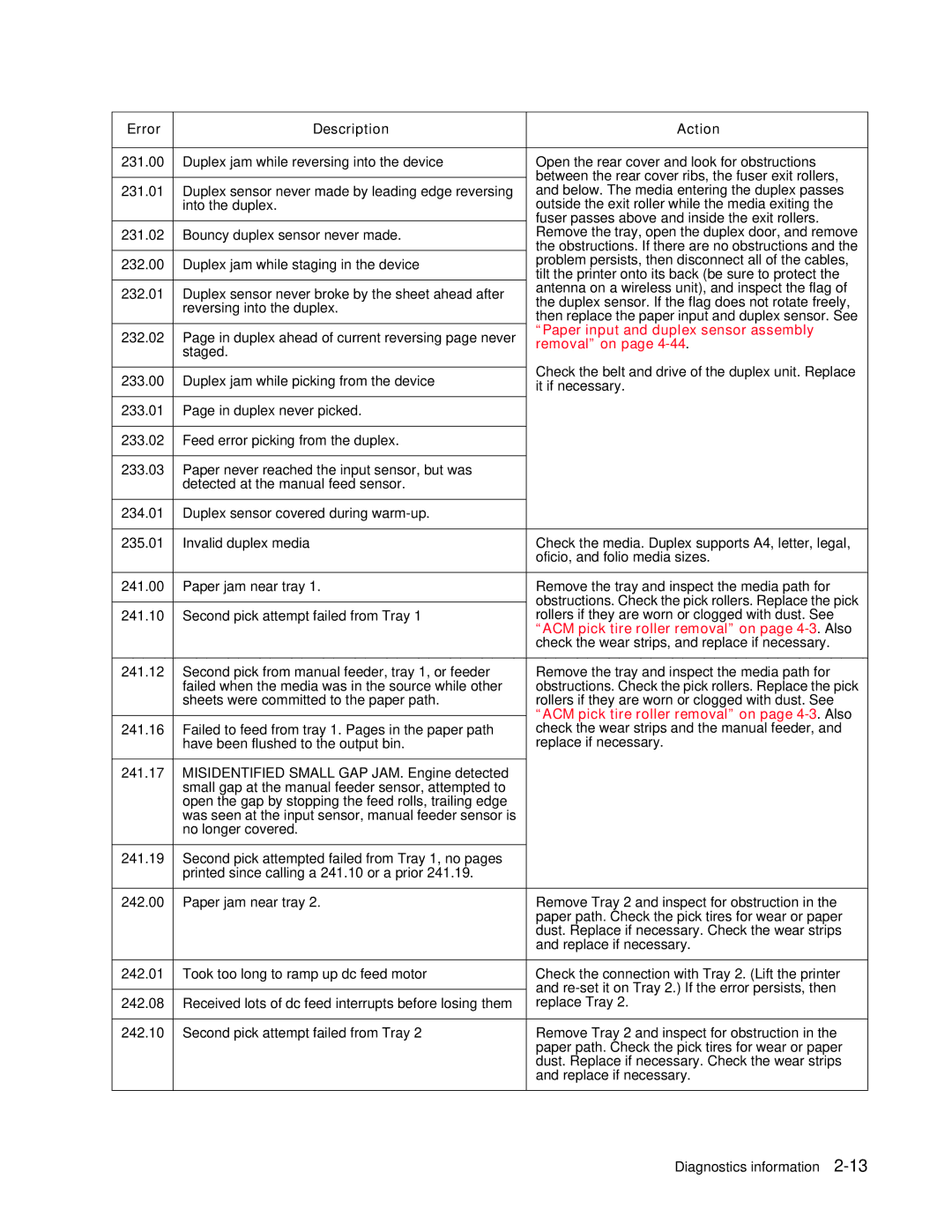

Error | Description | Action | |

|

|

| |

231.00 | Duplex jam while reversing into the device | Open the rear cover and look for obstructions | |

|

| between the rear cover ribs, the fuser exit rollers, | |

|

| ||

231.01 | Duplex sensor never made by leading edge reversing | and below. The media entering the duplex passes | |

| into the duplex. | outside the exit roller while the media exiting the | |

|

| fuser passes above and inside the exit rollers. | |

|

| ||

231.02 | Bouncy duplex sensor never made. | Remove the tray, open the duplex door, and remove | |

|

| the obstructions. If there are no obstructions and the | |

232.00 | Duplex jam while staging in the device | problem persists, then disconnect all of the cables, | |

tilt the printer onto its back (be sure to protect the | |||

|

| ||

232.01 | Duplex sensor never broke by the sheet ahead after | antenna on a wireless unit), and inspect the flag of | |

the duplex sensor. If the flag does not rotate freely, | |||

| reversing into the duplex. | ||

| then replace the paper input and duplex sensor. See | ||

|

| ||

|

| “Paper input and duplex sensor assembly | |

232.02 | Page in duplex ahead of current reversing page never | ||

removal” on page | |||

| staged. | ||

|

| ||

|

| Check the belt and drive of the duplex unit. Replace | |

233.00 | Duplex jam while picking from the device | ||

it if necessary. | |||

|

| ||

|

|

| |

233.01 | Page in duplex never picked. |

| |

|

|

| |

233.02 | Feed error picking from the duplex. |

| |

|

|

| |

233.03 | Paper never reached the input sensor, but was |

| |

| detected at the manual feed sensor. |

| |

|

|

| |

234.01 | Duplex sensor covered during |

| |

|

|

| |

235.01 | Invalid duplex media | Check the media. Duplex supports A4, letter, legal, | |

|

| oficio, and folio media sizes. | |

|

|

| |

241.00 | Paper jam near tray 1. | Remove the tray and inspect the media path for | |

|

| obstructions. Check the pick rollers. Replace the pick | |

|

| ||

241.10 | Second pick attempt failed from Tray 1 | rollers if they are worn or clogged with dust. See | |

|

| “ACM pick tire roller removal” on page | |

|

| check the wear strips, and replace if necessary. | |

|

|

| |

241.12 | Second pick from manual feeder, tray 1, or feeder | Remove the tray and inspect the media path for | |

| failed when the media was in the source while other | obstructions. Check the pick rollers. Replace the pick | |

| sheets were committed to the paper path. | rollers if they are worn or clogged with dust. See | |

|

| “ACM pick tire roller removal” on page | |

|

| ||

241.16 | Failed to feed from tray 1. Pages in the paper path | check the wear strips and the manual feeder, and | |

| have been flushed to the output bin. | replace if necessary. | |

|

|

| |

241.17 | MISIDENTIFIED SMALL GAP JAM. Engine detected |

| |

| small gap at the manual feeder sensor, attempted to |

| |

| open the gap by stopping the feed rolls, trailing edge |

| |

| was seen at the input sensor, manual feeder sensor is |

| |

| no longer covered. |

| |

|

|

| |

241.19 | Second pick attempted failed from Tray 1, no pages |

| |

| printed since calling a 241.10 or a prior 241.19. |

| |

|

|

| |

242.00 | Paper jam near tray 2. | Remove Tray 2 and inspect for obstruction in the | |

|

| paper path. Check the pick tires for wear or paper | |

|

| dust. Replace if necessary. Check the wear strips | |

|

| and replace if necessary. | |

|

|

| |

242.01 | Took too long to ramp up dc feed motor | Check the connection with Tray 2. (Lift the printer | |

|

| and | |

|

| ||

242.08 | Received lots of dc feed interrupts before losing them | replace Tray 2. | |

|

|

| |

242.10 | Second pick attempt failed from Tray 2 | Remove Tray 2 and inspect for obstruction in the | |

|

| paper path. Check the pick tires for wear or paper | |

|

| dust. Replace if necessary. Check the wear strips | |

|

| and replace if necessary. | |

|

|

|

Diagnostics information