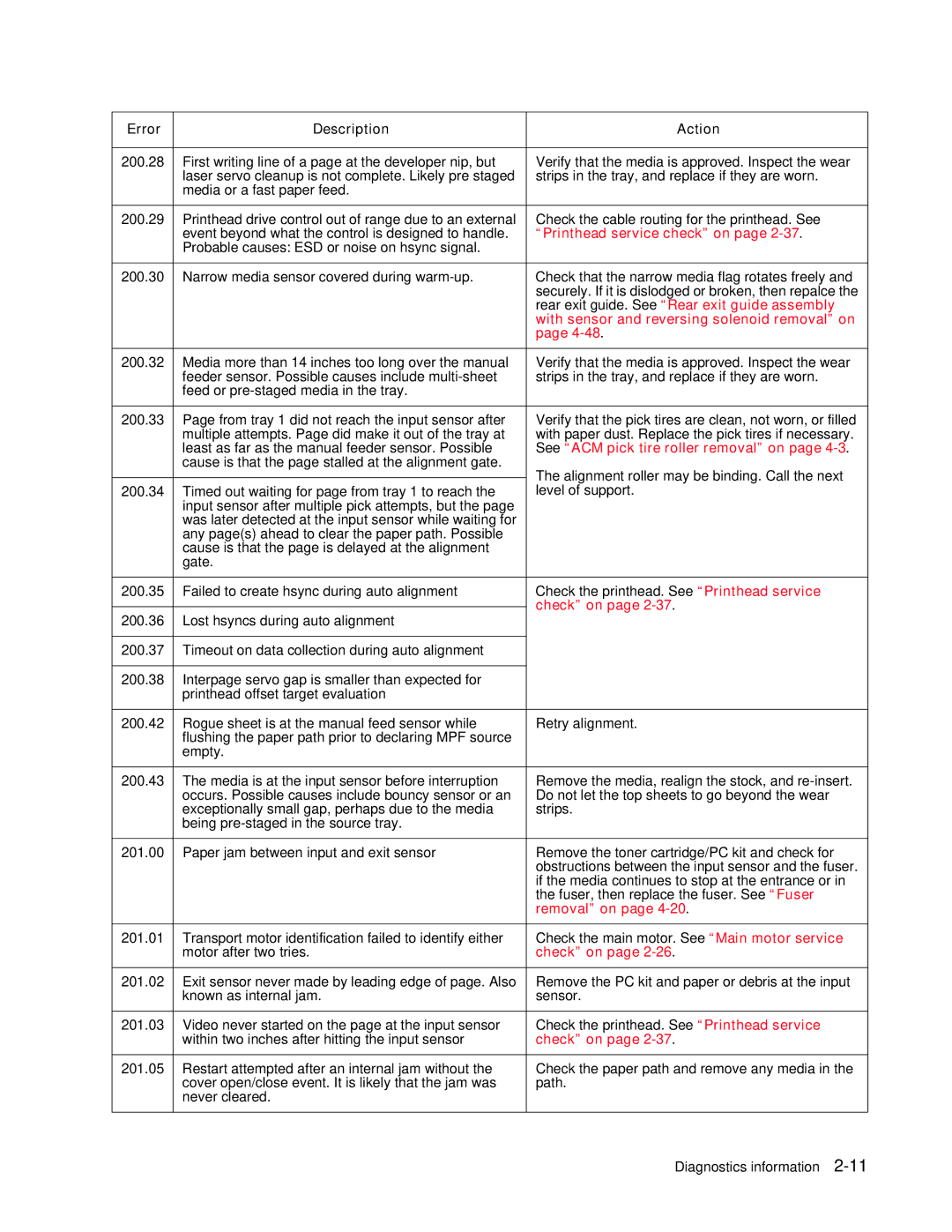

Error | Description | Action | |

|

|

| |

200.28 | First writing line of a page at the developer nip, but | Verify that the media is approved. Inspect the wear | |

| laser servo cleanup is not complete. Likely pre staged | strips in the tray, and replace if they are worn. | |

| media or a fast paper feed. |

| |

|

|

| |

200.29 | Printhead drive control out of range due to an external | Check the cable routing for the printhead. See | |

| event beyond what the control is designed to handle. | “Printhead service check” on page | |

| Probable causes: ESD or noise on hsync signal. |

| |

|

|

| |

200.30 | Narrow media sensor covered during | Check that the narrow media flag rotates freely and | |

|

| securely. If it is dislodged or broken, then repalce the | |

|

| rear exit guide. See “Rear exit guide assembly | |

|

| with sensor and reversing solenoid removal” on | |

|

| page | |

|

|

| |

200.32 | Media more than 14 inches too long over the manual | Verify that the media is approved. Inspect the wear | |

| feeder sensor. Possible causes include | strips in the tray, and replace if they are worn. | |

| feed or |

| |

|

|

| |

200.33 | Page from tray 1 did not reach the input sensor after | Verify that the pick tires are clean, not worn, or filled | |

| multiple attempts. Page did make it out of the tray at | with paper dust. Replace the pick tires if necessary. | |

| least as far as the manual feeder sensor. Possible | See “ACM pick tire roller removal” on page | |

| cause is that the page stalled at the alignment gate. | The alignment roller may be binding. Call the next | |

|

| ||

|

| ||

200.34 | Timed out waiting for page from tray 1 to reach the | level of support. | |

| input sensor after multiple pick attempts, but the page |

| |

| was later detected at the input sensor while waiting for |

| |

| any page(s) ahead to clear the paper path. Possible |

| |

| cause is that the page is delayed at the alignment |

| |

| gate. |

| |

|

|

| |

200.35 | Failed to create hsync during auto alignment | Check the printhead. See “Printhead service | |

|

| check” on page | |

200.36 | Lost hsyncs during auto alignment | ||

| |||

|

|

| |

200.37 | Timeout on data collection during auto alignment |

| |

|

|

| |

200.38 | Interpage servo gap is smaller than expected for |

| |

| printhead offset target evaluation |

| |

|

|

| |

200.42 | Rogue sheet is at the manual feed sensor while | Retry alignment. | |

| flushing the paper path prior to declaring MPF source |

| |

| empty. |

| |

|

|

| |

200.43 | The media is at the input sensor before interruption | Remove the media, realign the stock, and | |

| occurs. Possible causes include bouncy sensor or an | Do not let the top sheets to go beyond the wear | |

| exceptionally small gap, perhaps due to the media | strips. | |

| being |

| |

|

|

| |

201.00 | Paper jam between input and exit sensor | Remove the toner cartridge/PC kit and check for | |

|

| obstructions between the input sensor and the fuser. | |

|

| if the media continues to stop at the entrance or in | |

|

| the fuser, then replace the fuser. See “Fuser | |

|

| removal” on page | |

|

|

| |

201.01 | Transport motor identification failed to identify either | Check the main motor. See “Main motor service | |

| motor after two tries. | check” on page | |

|

|

| |

201.02 | Exit sensor never made by leading edge of page. Also | Remove the PC kit and paper or debris at the input | |

| known as internal jam. | sensor. | |

|

|

| |

201.03 | Video never started on the page at the input sensor | Check the printhead. See “Printhead service | |

| within two inches after hitting the input sensor | check” on page | |

|

|

| |

201.05 | Restart attempted after an internal jam without the | Check the paper path and remove any media in the | |

| cover open/close event. It is likely that the jam was | path. | |

| never cleared. |

| |

|

|

|

Diagnostics information