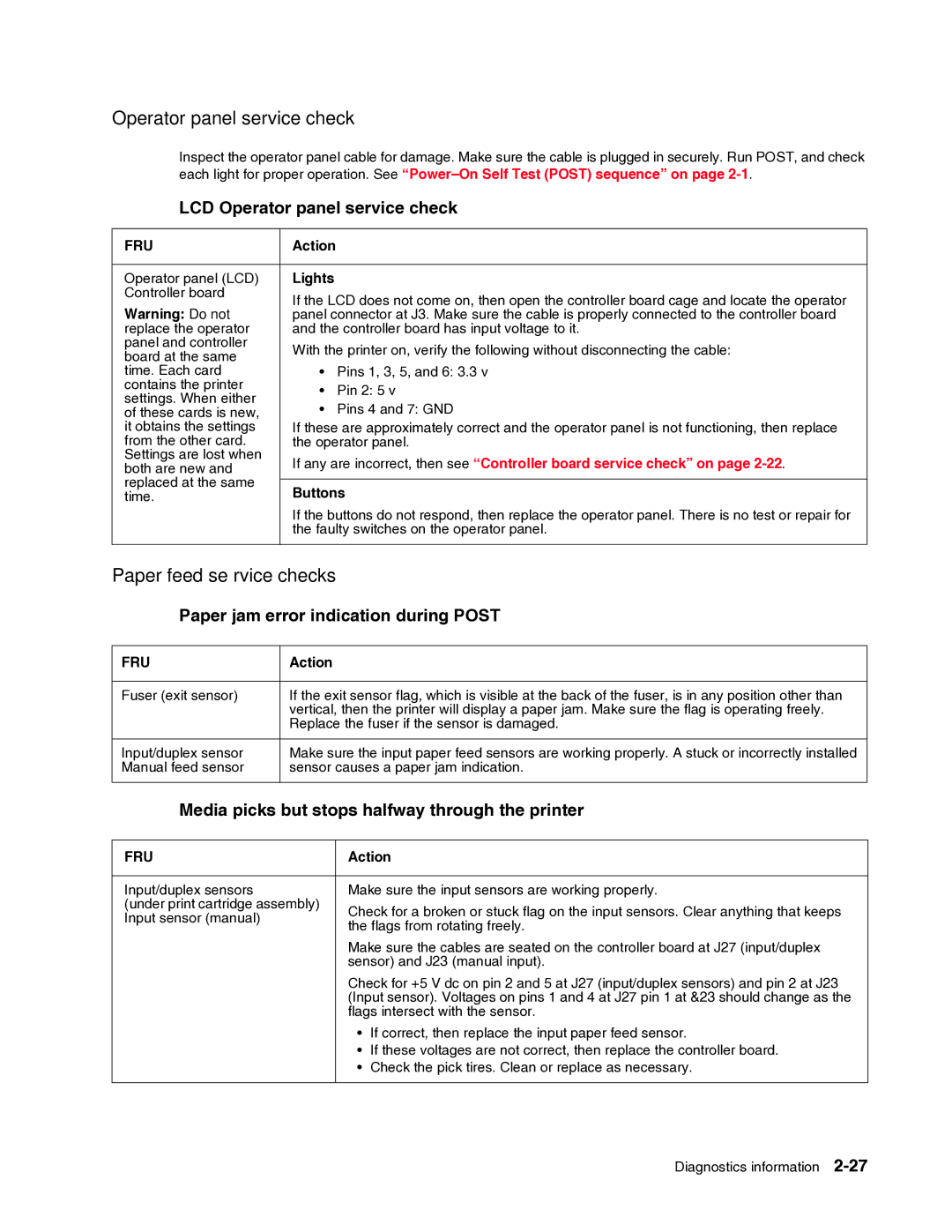

Operator panel service check

Inspect the operator panel cable for damage. Make sure the cable is plugged in securely. Run POST, and check each light for proper operation. See

LCD Operator panel service check

FRU | Action | |

|

| |

Operator panel (LCD) | Lights | |

Controller board | If the LCD does not come on, then open the controller board cage and locate the operator | |

Warning: Do not | ||

panel connector at J3. Make sure the cable is properly connected to the controller board | ||

replace the operator | and the controller board has input voltage to it. | |

panel and controller | With the printer on, verify the following without disconnecting the cable: | |

board at the same | ||

| ||

time. Each card | • Pins 1, 3, 5, and 6: 3.3 v | |

contains the printer | • Pin 2: 5 v | |

settings. When either | ||

• Pins 4 and 7: GND | ||

of these cards is new, | ||

it obtains the settings | If these are approximately correct and the operator panel is not functioning, then replace | |

from the other card. | the operator panel. | |

Settings are lost when | If any are incorrect, then see “Controller board service check” on page | |

both are new and | ||

replaced at the same |

| |

Buttons | ||

time. | ||

| If the buttons do not respond, then replace the operator panel. There is no test or repair for | |

| the faulty switches on the operator panel. | |

|

|

Paper feed service checks

Paper jam error indication during POST

FRU | Action |

|

|

Fuser (exit sensor) | If the exit sensor flag, which is visible at the back of the fuser, is in any position other than |

| vertical, then the printer will display a paper jam. Make sure the flag is operating freely. |

| Replace the fuser if the sensor is damaged. |

|

|

Input/duplex sensor | Make sure the input paper feed sensors are working properly. A stuck or incorrectly installed |

Manual feed sensor | sensor causes a paper jam indication. |

|

|

Media picks but stops halfway through the printer | |

FRU | Action | ||

|

| ||

Input/duplex sensors | Make sure the input sensors are working properly. | ||

(under print cartridge assembly) | Check for a broken or stuck flag on the input sensors. Clear anything that keeps | ||

Input sensor (manual) | |||

the flags from rotating freely. | |||

| |||

| Make sure the cables are seated on the controller board at J27 (input/duplex | ||

| sensor) and J23 (manual input). | ||

| Check for +5 V dc on pin 2 and 5 at J27 (input/duplex sensors) and pin 2 at J23 | ||

| (Input sensor). Voltages on pins 1 and 4 at J27 pin 1 at &23 should change as the | ||

| flags intersect with the sensor. | ||

| • | If correct, then replace the input paper feed sensor. | |

| • | If these voltages are not correct, then replace the controller board. | |

| • | Check the pick tires. Clean or replace as necessary. | |

|

|

| |

Diagnostics information