Please read carefully before using the Opsys MW

Opsys MW Microplate Washer

User’s Guide

Chantilly, VA 20151-1683 USA Tel. 703 800 288-2354 Fax. 703

Part No. 91000051, Revision B

This manual is published by DYNEX Technologies, Inc

DYNEX Technologies 14340 Sullyfield Circle

Warranty and Special Provisions Limited Warranty

Page

Chapter 3 Configuration

Table of Contents

Table of Contents

Chapter 2 Installation

Opsys MW User’s Guide

Chapter 7 Troubleshooting

Chapter 8 Service

Index

About this Manual

About this Manual

This manual gives you the information needed to

This page is intentionally left blank

Chapter 1 Introduction

Description

Description

Programming

Wash Head

Wash Head

Description

Dispense Height

Wash Head Positions

Wash Head Position

Description

Waste

Wash Fluid

Description

Features

Features

Features

Specifications

Specifications

Dimensions and Weight

Power Requirements

Assay Programming

Input Ranges

Standards

Plate Setup

Warning Labels

Warning Labels

Label Description

Warning Labels

Chapter 2 Installation Unpacking

Materials Provided

Unpacking

To unpack the components

Hardware Components

Hardware Components

Keypad. The keypad is used by the operator to select commands and enter wash parameters

Figure 3. Rear View of the Opsys MW System

Connectors at the rear of the Opsys MW system are shown in Figure

Positioning the Instrument

Positioning the Instrument

Installing the Wash Head

Installing the Wash Head

Installing the Wash Container

To install the Wash Container

Installing the Wash Container

Installing the Waste Container

To install the Waste Container and Foam/Aerosol Trap

Installing the Waste Container

1. Connect the Opsys MW to the laboratory electrical supply outlet

Turning on the System

Turning on the System

SETUP PROGRAM

Chapter 3 Configuration The Keypad

The Keypad

7 8 9

If you are entering or editing information , a

“Cancel” key

Purpose

Scroll keys

pressing the key once. If the key is pressed two to

Alphanumeric

Keys

The numeral shown on the key is displayed by

Menus

SETUP

Configure the Instrument

Menus

The PROGRAM Menu

The SETUP Menu

CLEAN

Configuring the System

Configuring the System

Command

Specifying the Wash Head

Specifying Plate Parameters

To specify parameters for a plate type

Note The default value is displayed. Select SHOW to move the wash head to the default well top position so that the height can be checked. Then, determine the correct value as outlined on page 30. Repeat the procedure as needed

Sweep height? SHOW

Configuring the System

Displaying the Software Version

Note Refer to page 74 for additional pump calibration instructions

Specifying the Pump Parameters

Selecting Clean

Configuring the System

Purge

Chapter 4 Wash Protocols Wash Protocol Operations

Wash Protocol Operations

Operation

Dispense

Soak

Fill

Creating a New Wash Protocol

Specifying the Header

Creating a New Wash Protocol

To create a new wash protocol header

9. If YES is selected, the display will read Constant timing? YESNO

7. Re-enter the password and press ENTER. The display will read

Select plate 2 DYNEX1

Variable strips? YESNO

Select option MOVE PURGE

Specifying Wash Cycle Operations

To specify a Purge

To specify a Move cycle

Note An Aspirate or Dispense must be

To specify an Aspiration within a Move

Note A Dispense or Aspirate must be performed within a Move cycle

To specify a Dispense within a Move

Opsys MW User’s Guide

To specify a Soak within a Move

To specify a Fill within a Move

Note A volume ranging from 50 to 300 microliters can be entered

Note A Fill must be performed within a Move cycle

Select option END LOOP 3. Select END LOOP. The display will read

Ending a MOVE Cycle

Select option SOAK FILL

2. Scroll right to display the next selection. The display will read

To specify a Soak outside of a Move

Select option SOAK END 2. Select END. The display will read 1 NAME01

To specify the End of the wash protocol

Modifying a Wash Protocol

To modify a wash protocol

Modifying a Wash Protocol

MOVE

To modify a wash operation

To delete a wash operation

To insert a wash operation

Copying a Wash Protocol

To copy a wash protocol

Copying a Wash Protocol

Overwrite test? NO YESNO 8. Select YES. The display will read

7 NAME04 SETUP PROGRAM

Preparation

Chapter 5 Washing a Plate

Preparation

To empty the waste container

To refill the wash container

Washing a Plate

To wash a plate

Washing a Plate

Washing a Plate

Six month maintenance

Chapter 6 Routine Maintenance Routine Maintenance Procedures

Daily maintenance

Weekly maintenance

As required maintenance

To decontaminate the system

Cleaning and Decontamination

To clean the system

Cleaning and Decontamination

Cleaning the Containers

To empty and clean the waste container

Cleaning the Containers

Replacing the Tubing

To replace the dispense tubing

Replacing the Tubing

To replace the vacuum tubing

To replace the waste tubing

Pump Calibration

Calibration Protocol

Pump Calibration

8. If the dispensed volume is too high, decrease the pump speed using the SETUP/CAL function refer to page

Pump Calibration

Resolution

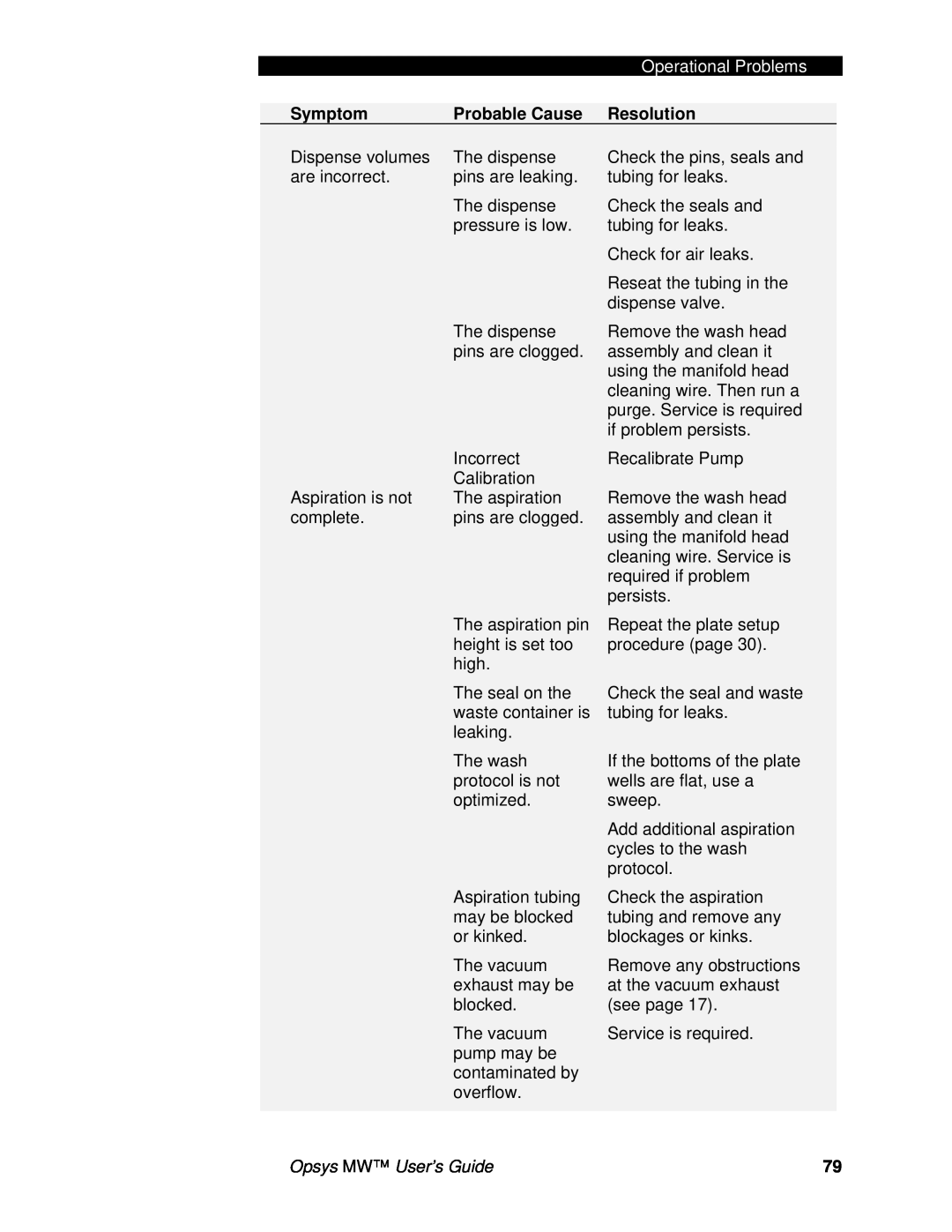

Chapter 7 Troubleshooting Operational Problems

Operational Problems

Symptom

Probable Cause

waste container is

Test Too Large is

High Waste Level

X Motor Home

Z Motor Home

To replace the wash head assembly

Chapter 8 Service Service Procedures

To remove the wash head assembly

To clean the wash head assembly

Hardware

Accessories

Spare Parts

Major Assemblies

Returning a Washer for Service

To return a Washer for service

Returning a Washer for Service

Suggested decontamination methods

EQUIPMENT IN TRANSIT

EQUIPMENT DECLARATION

CERTIFICATE OF DECONTAMINATION

Contact DYNEX Technologies

Contact DYNEX Technologies

DYNEX Technologies 14340 Sullyfield Circle Chantilly, VA 20151 USA

Index

Index

variable strips, 41 warning labels, 11 Wash Container, 5