DMC-3425

By Galil Motion Control, Inc

Page

Contents

Connecting Hardware

Programming Motion

Application Programming 107

DAC

ZOH

J5 Power 6 PIN Molex

Warranty

Overview

Introduction

Standard Servo Motors with +/- 10 Volt Command Signal

Stepper Motor with Step and Direction Signals

Overview of Motor Types

Brushless Servo Motor with Sinusoidal Commutation

DMC-3425 Overview

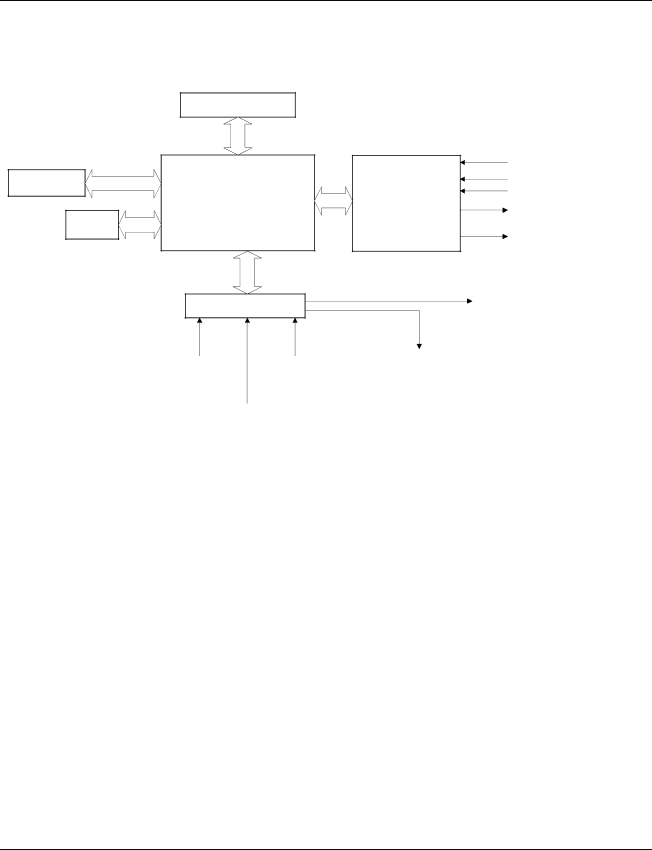

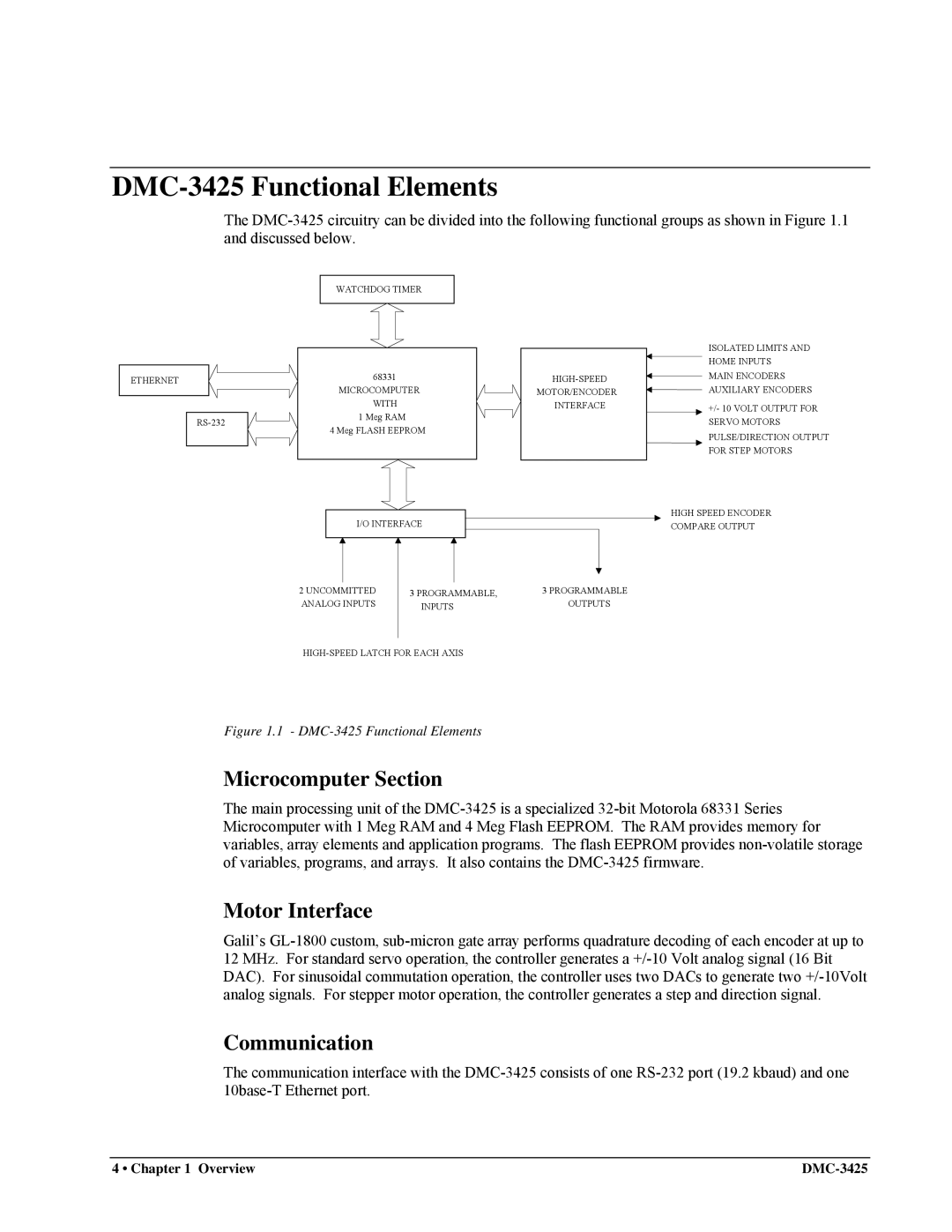

DMC-3425 Functional Elements

Microcomputer Section

Motor Interface

Communication

General I/O

System Elements

Motor

Amplifier Driver

Watch Dog Timer

Encoder

Getting Started

DMC-3425 Motion Controller

Installing the DMC-3425 Controller

Elements You Need

Determine Overall Motor Configuration

Configuring Jumpers on the DMC-3425

Setting the Baud Rate on the DMC-3425

Selecting MO as default on the DMC-3425

Stepper Motor Jumpers

9600 1200

Axis Configuration Jumpers

A1 A2 A4 A8

Installing the Communications Software

Using Galil Software for DOS

Using Galil Software for Windows

Getting Started DMC-3425

Using Non-Galil Communication Software

Sending Test Commands to the Terminal

Communicating through the Ethernet

TPA CR

Address

Set-up axis for sinusoidal commutation optional

Make connections to amplifier and encoder

Getting Started DMC-3425

Connect Standard Servo Motor

Check the Polarity of the Feedback Loop

MO CR

Inverting the Loop Polarity

SH CR

BG CR

TT CR

Power Supply

Connect brushless motor for sinusoidal commutation

If Hall Sensors are Available

If Hall Sensors are Not Available

Connect Step Motors

BGA CR

Amacr

BC CR

Tune the Servo System

TE CR

Configure the Distributed Control System

Configuring Operation for Distributed Control

Automatic Configuration of Distributed Control

Manual Slave IP configuration with HC command

Manual Configuration of Distributed Control

#SETUP

Mgconfiguration Failed Else Mgconfig Success Endif

Instruction Interpretation

NA6

CHC=D,E

CHE=F,G

Design Examples

Example 1 System Set-up

Example 2 Profiled Move

Example 3 Position Interrogation

Example 8 Operation in the Buffer Mode

Example 5 Velocity Control Jogging

Example 6 Operation Under Torque Limit

Example 7 Interrogation

Example 9 Motion Programs

Example 10 Motion Programs with Loops

Example 11- Motion Programs with Trippoints

Example 12 Control Variables

Example 13 Control Variables and Offset

Return to top of program

Using Inputs

Limit Switch Input

Overview

Home Switch Input

Abort Input

Amplifier Interface

Uncommitted Digital Inputs

TTL Inputs

Analog Inputs

TTL Outputs

This page Left Blank Intentionally

RS-232 Configuration

RS232 Port

RS232 Port 1 Dataterm

Baud Rate Selection

Ethernet Configuration

Communication Protocols

Addressing

Handshaking Modes

Ethernet Handles

Global vs. Local Operation

Local Operation

Accessing the I/O of the Slaves

Operation of Distributed Control

Handling Communication Errors

Multicasting

Digital Outputs

Digital Inputs

Unsolicited Message Handling

IOC-7007 Support

Modbus Support

Function Code Definition

Handle Switching

Handle Restore on Communication Failure

Other Communication Options

User Defined Ethernet Variables

Data Record

Data Record Map

Waiting on Handle Responses

DMC-3425 Communication

Communication DMC-3425

Axis Switch Information 1 Byte

Header Information Byte 0, 1 of Header

Bytes 2, 3 of Header

General Status Information 1 Byte

QZ Command

Axis Status Information 2 Byte

Coordinated Motion Status Information for plane 2 Byte

Using Third Party Software

This page Left Blank Intentionally

Command Syntax Ascii

Important All DMC-3425 commands are sent in upper case

Command Syntax Binary

Coordinated Motion with more than 1 axis

Binary Command Format

Byte

Header Format

Binary command table

Datafields Format

Example

LE, VE

Controller Response to Data

Interrogation Commands

Summary of Interrogation Commands

Interrogating Current Commanded Values

Interrogating the Controller

Command Summary

This page Left Blank Intentionally

Programming Motion

Mode of Motion Basic description Commands Global

Independent Axis Positioning

VP, CR

Command Summary Independent Axis

Operand Summary Independent Axis

Examples

Absolute Position Movement

InstructionInterpretation

BG C

Command Summary Jogging

Independent Jogging

Jog in a and C axes

Linear Interpolation Mode Local Mode

Specifying Linear Segments

Joystick Jogging

Additional Commands

Specifying Vector Speed for Each Segment

#ALT

Lmab

Command Summary Linear Interpolation

Operand Summary Linear Interpolation

Changing Feedrate

BGS

Example

Example Linear Move

Linear Interpolation Motion

#LMOVE

Example Multiple Moves

#LOAD

Vector Mode Linear and Circular Interpolation Local Mode

Specifying Vector Segments

Additional commands

Command Summary Coordinated Motion Sequence

Compensating for Differences in Encoder Resolution

Operand Summary Coordinated Motion Sequence

Trippoints

VM AB

Required Path

Electronic Gearing Local Mode

Command Summary Electronic Gearing

Example Gantry Mode

Example Electronic Gearing

Electronic Cam Local Mode

GA, CA

BGB

GA,A

Programming Motion DMC-3425

DMC-3425 Programming Motion

3000 2250 1500 2000 4000 6000 Master

EAA

#LOOP

#RUN

EB1

#LOOPJP#LOOP,V1=0

ST a

Contour Mode Local Mode

Specifying Contour Segments

Instruction Description

CMA

DT0CD0

Command Summary Contour Mode

Operand Summary Contour Mode

General Velocity Profiles

Generating an Array An Example

Contour Mode Example

#POINTS

POSC=V4

Teach Record and Play-Back

Record and Playback Example

Virtual Axis Local Mode

Mode of Motion Virtual Axis usage Commands

Stepper Motor Operation

Ecam Master Example

Sinusoidal Motion Example

Specifying Stepper Motor Operation

Monitoring Generated Pulses vs. Commanded Pulses

Stepper Motor Smoothing

Using an Encoder with Stepper Motors

Command Summary Stepper Motor Operation

Motion Complete Trippoint

Operand Summary Stepper Motor Operation

Using the CE Command

Additional Commands for the Auxiliary Encoder

Dual Loop Auxiliary Encoder

Backlash Compensation

Continuous Dual Loop

Sampled Dual Loop

#DUALOOP

DE0

Using the IT and VT Commands

Motion Smoothing

JP#CORRECT

#END

Homing

Trapezoidal velocity and smooth velocity profiles

#HOME

HM a

AM a

MG AT Home

Home Switch

Command Summary Homing Operation

High Speed Position Capture Latch

Operand Summary Homing Operation

Input Function

AL B

This page Left Blank Intentionally

Application Programming

Global vs. Local Programming

Edit Mode Commands

Entering Programs

Return

ED #BEGIN

Using Labels in Programs

Program Format

Valid labels

Invalid labels

No Command and the Apostrophe ‘

Special Labels

Commenting Programs

REM Command

Executing Programs Multitasking

Debugging Programs

Trace Command

Error Code Command

Stop Code Command

RAM Memory Interrogation Commands

Breakpoints and single stepping

Eeprom Memory Interrogation Operands

Program Flow Commands

Event Triggers & Trippoints

DMC-3425 Event Triggers

Example- Multiple Move Sequence

AS a B C D E F G H

Example- Set Output after Distance

Example- Repetitive Position Trigger

Example Start Motion on Input

Example Set Output when At Speed

Example Change Speed along Vector Path

Example Multiple Move with Wait

Example- Define Output Waveform Using AT

Command Format JP and JS

Conditional Jumps

Format

Example using variables named V1, V2, V3

Logical operators

Conditional Statements

Multiple Conditional Statements

Using the if and Endif Commands

If, Else, and Endif

Examples

Using the Else Command

Command Format IF, Else and Endif

Nesting if Conditional Statements

Format Description

Auto-Start and Auto Error Routine

Subroutines

Stack Manipulation

Example Limit Switch

Example Position Error

Automatic Subroutines for Monitoring Conditions

Example Motion Complete Timeout

Example Command Error

Example Input Interrupt

Example Command Error w/Multitasking

Example Ethernet Communication Error

Mathematical and Functional Expressions

Mathematical Operators

Operator Function

Bit-Wise Operators

ENTER,LENS6

FLEN=@FRACLEN

LEN1=FLEN&$00FF

Variables

Functions

POS

PR Posa

Programmable Variables

Assigning Values to Variables

Assigning Variable Values to Controller Parameters

Displaying the value of variables at the terminal

Example Using Variables for Joystick

Operands

Special Operands

Instruction

Arrays

Defining Arrays

Assignment of Array Entries

Using a Variable to Address Array Elements

Uploading and Downloading Arrays to On Board Memory

Automatic Data Capture into Arrays

Command Summary Automatic Data Capture

Data Types for Recording

Operand Summary Automatic Data Capture

Example Recording into An Array

Outputting Numbers and Strings

Deallocating Array Space

Sending Messages

Specifying the Port for Messages

Using the MG Command to Configure Terminals

Formatting Messages

MG STR S3

Displaying Variables and Arrays

Summary of Message Functions

Example Printing a Variable and an Array element

Function Description

Local Formatting of Response of Interrogation Commands

LZ0

LZ1

Formatting Variables and Array Elements

Local Formatting of Variables

VF1

V1=ALPHA

Hardware I/O

Converting to User Units

Digital Outputs

Example- Set Bit and Clear Bit

Example Using Inputs to control program flow

Example Start Motion on Switch

Digital Inputs

Example- Output Port

Input Interrupt Function

Analog Inputs

Example Position Follower Point-to-Point

Configuring the I/O of the DMC-3425

Extended I/O of the DMC-3425 Controller

Example Position Follower Continuous Move

Accessing Extended I/O

Saving the State of the Outputs in Non-Volatile Memory

Bit I/O Block Binary Representation Decimal Value for

Wire Cutter

Example Applications

Interfacing to Grayhill or OPTO-22 G4PB24

Argument Blocks Bits Description

X-Y Table Controller

JP #A

BGC

AMC

BGC AMC

Speed Control by Joystick

BGS AMS

Position Control by Joystick

JG VEL JP #B

This page Left Blank Intentionally

Hardware Protection

Output Protection Lines

Signal or Function State if Error Occurs

Software Protection

Input Protection Lines

Programmable Position Limits

Off-On-Error

Automatic Error Routine

#AJP #AEN

Limit Switch Routine

Limit Switch Example

Installation

Symptom Cause Remedy

Symptom Cause

Communication

Stability

Operation

Theory of Operation

Level

Operation of Closed-Loop Systems

Velocity and Position Profiles

System Modeling

Functional Elements of a Motion Control System

Motor-Amplifier

Voltage Drive

Current Drive

Velocity Loop

Elements of velocity loops

Voltage Source

DAC

Digital Filter

System Analysis

ZOH

Motor Ms = P/I = Kt/Js2 = 500/s2 rad/A Amp Ka = 4 Amp/V

System Design and Compensation

Analytical Method

Kd = 10/32768 = Encoder Kf = 4N/2π =

DMC-3425 Theory of Operation

Equivalent Filter Form

KP, KD, KI, PL

PID, T

Electrical Specifications

Performance Specifications

Power Requirements

Servo Control

Connectors for DMC-3425

J3 DMC-3425 General I/O 37- PIN D-type

Acmda Pwma

Acmdy Signa

J3 DMC-3425-Stepper General I/O 37- PIN D-type

Pwmb

Signb Pwma

Signa

Pin-Out Description

J1 RS232 Main port DB-9 Pin Male

DCD DTR GND DSR RTS CTS

RTS CTS GND

Features

Specifications

ICM-1460 Interconnect Module

Reset

ERROR/PULSEY

AMPEN/SIGNY5

ACMDX/PULSEX

Opto-Isolation Option for ICM-1460

Opto-isolated inputs

Opto-isolated outputs

Figure A-1

Configuring the I/O of the DMC-3425 with DB-14064

CO n

Accessing extended I/O

Saving the State of the Outputs in Non-Volatile Memory

Connector Description

J6 50-PIN IDC Pin Signal Block Bit @INn Bit No @OUTn

Block Bit @INn Bit No @OUTn

IOM-1964 Opto-Isolation Module for Extended I/O Controllers

Description

Overview

Buffer chips

Configuring Hardware Banks

Figure A-4

Input Circuit

High Power Digital Outputs

Figure A-6

Output Command Result

Standard Digital Outputs

Electrical Specifications

High Power Digital Outputs

Standard Digital Outputs

Relevant DMC Commands

Screw Terminal Listing

DMC-3425 Appendices

PWROUT32

PWROUT31

PWROUT30

PWROUT29

Coordinated Motion Mathematical Analysis

1000 2000

Velocity

100000 = 0.05 s 2000000

List of Other Publications

Training Seminars

WHO should Attend

Contacting Us

Galil Motion Control

Warranty

Index

Eeprom

Homing, 38

Eeprom

Index DMC-3425