pH ARC Sensors Modbus RTU Programmer’s Manual (EPHUM011)

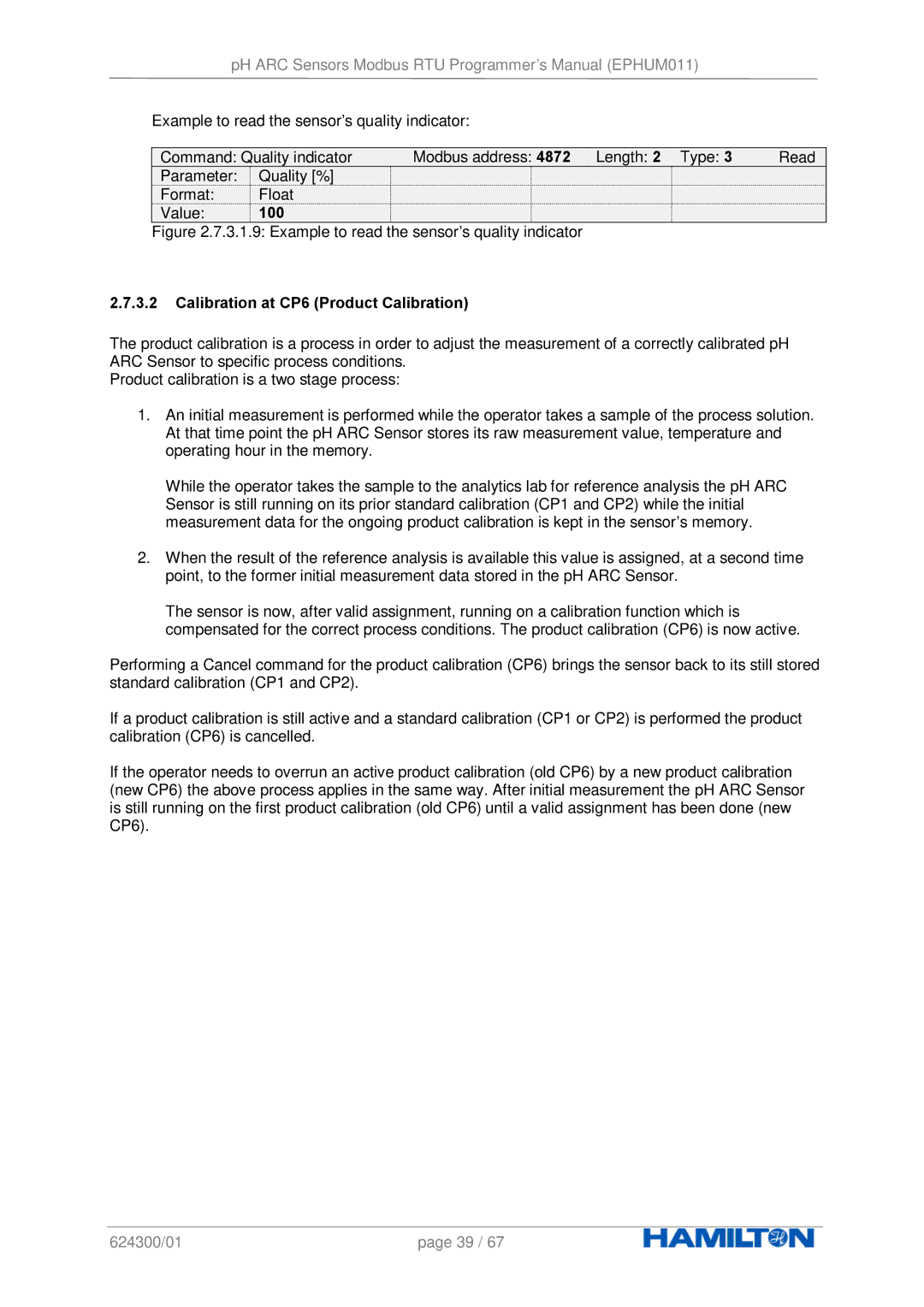

Example to read the sensor’s quality indicator:

Command: Quality indicator | Modbus address: 4872 | Length: 2 | Type: 3 | Read | |

Parameter: | Quality [%] |

|

|

|

|

Format: | Float |

|

|

|

|

Value: | 100 |

|

|

|

|

Figure 2.7.3.1.9: Example to read the sensor’s quality indicator

2.7.3.2Calibration at CP6 (Product Calibration)

The product calibration is a process in order to adjust the measurement of a correctly calibrated pH ARC Sensor to specific process conditions.

Product calibration is a two stage process:

1.An initial measurement is performed while the operator takes a sample of the process solution. At that time point the pH ARC Sensor stores its raw measurement value, temperature and operating hour in the memory.

While the operator takes the sample to the analytics lab for reference analysis the pH ARC Sensor is still running on its prior standard calibration (CP1 and CP2) while the initial measurement data for the ongoing product calibration is kept in the sensor’s memory.

2.When the result of the reference analysis is available this value is assigned, at a second time point, to the former initial measurement data stored in the pH ARC Sensor.

The sensor is now, after valid assignment, running on a calibration function which is compensated for the correct process conditions. The product calibration (CP6) is now active.

Performing a Cancel command for the product calibration (CP6) brings the sensor back to its still stored standard calibration (CP1 and CP2).

If a product calibration is still active and a standard calibration (CP1 or CP2) is performed the product calibration (CP6) is cancelled.

If the operator needs to overrun an active product calibration (old CP6) by a new product calibration (new CP6) the above process applies in the same way. After initial measurement the pH ARC Sensor is still running on the first product calibration (old CP6) until a valid assignment has been done (new CP6).

624300/01 | page 39 / 67 |