HP Color LaserJet CM1312 MFP Series

Page

HP Color LaserJet CM1312 MFP Series

Copyright and License

Trademark Credits

Table of contents

Use product features

Use the product with Macintosh

Connectivity

Paper and print media

Copy

Print tasks

Color for Windows

Scan

Fax fax models only

Photo

Problem solve

Manage and maintain the product

Appendix B Service and support

Appendix a Supplies and accessories

Appendix C Specifications

Appendix D Regulatory information

253

Enww

Product basics

Product is available in the following configurations

Product comparison

Product features

HP LaserJet CM1312 mfp front view

Product walkaround

HP LaserJet CM1312 mfp back view

HP LaserJet CM1312 fax/photo-card model front view

HP LaserJet CM1312 fax/photo-card model Back view

Interface ports

Control panel

Copy Features button access the Copy menu

Control-panel walkaround

HP LaserJet CM1312 control panel

Liquid Crystal Display OK button and navigation arrows

HP LaserJet CM1312 fax/photo-card model control panel

Control-panel Setup menu

1Copy setup menu

Control-panel menus

Use the control-panel menus

Sharpen Default sharpen setting for copies. Possible values

Values range from 1 to 11 with 6 being the default no

Values can be set for each of the following settings

Background Removal

3Photo setup menu

2Reports menu

4Fax setup menu fax models only

Menu Item Sub-menu item Description Default output Color

Question using the arrow keys

Menu Item Sub-menu item Description Fax Set-up Utility

Basic setup Time/Date

Answer mode Automatic

Fax Header Your fax number

Company name

On multiple pages

5System setup menu

Paper setup Default paper size Letter

Legal Default paper type Lists available

Cancel

Does not specify a size

After Power On

Adjust Alignment Print Test

Adjust Tray

Volume Settings Alarm volume Soft

6Service menu

7Network configuration menu

Enww

Fax Resolution Standard Fine

Send Send a fax

Redial

Send fax later

8Fax Menu

Navigate through the photos

9Photo Menu

10Copy Menu

Software for Windows

Full software installation Print and scan driver

Supported operating systems for Windows

Supported printer drivers for Windows

HP Universal Print Driver UPD

UPD installation modes

Upd

Select the correct printer driver for Windows

Priority for print settings

Change printer-driver settings for Windows

Printers and Other Hardware

Printer

Software installation types for Windows

Remove software for Windows

HP Web Jetadmin web only

Supported utilities for Windows

HP ToolboxFX

Embedded Web server

Software for other operating systems

Software

Use the product with Macintosh

Priority for print settings for Macintosh

Change printer-driver settings for Macintosh

Software for Macintosh

Supported operating systems for Macintosh

Remove software from Macintosh operating systems

Software installation types for Macintosh

Supported utilities for Macintosh

Enww

Use features in the Macintosh printer driver

Create and use printing presets in Macintosh

Print

Resize documents or print on a custom paper size

Use watermarks

Print multiple pages on one sheet of paper in Macintosh

Use the Services menu

Scan

Print on both sides of the page duplex printing

Use automatic duplex printing

Fax HP LaserJet CM1312 fax/photo-card model only

Scanning tasks

Photo

Enww

Connectivity

Supported network operating systems

USB connection

Service name Description

2Network product discovery

3Messaging and management

4IP addressing

That server

View settings

Change settings

Network configuration

Configuration

Set password

Manual configuration

Automatic configuration

IP address

Link speed setting

IPv4 and IPv6 settings

Enww

Paper and print media

Understand paper and print media use

Size Dimensions Tray

Supported paper and print media sizes

1Supported paper and print media sizes

2Supported envelopes and postcards

Media type Weight Capacity1 Paper orientation

Supported paper types and tray capacity

Special paper or print media guidelines

Media type Weight Capacity

Media type

Load paper and print media

Tray

Configure tray

Enww

Use product features

Economy settings

Archive print

Select fonts

Fonts

Print lists of available fonts

Enww

Print tasks

Cancel a print job

Use features in the Windows printer driver

Open the printer driver

Use printing shortcuts

Set paper and quality options

Obtain support and product-status information

Set document finishing options

Set advanced printing options

Printer Features section. b In the Print All Text as Black

Change print-quality settings

Print edge-to-edge originals

Enww

Copy

Load originals

Automatic document feeder ADF models only

Flatbed scanner

Cancel a copy job

Use copy

One-touch copy

Multiple copies

Adjust the default copy size

Reduction/enlargement settings

Reduce or enlarge copies

Reduce or enlarge copies for the current job

Change the copy-collation setting for the current job

Change the copy-collation setting

Change the default copy-collation setting

Copy settings

Adjust the copy quality for the current job

Color copies or black and white copies Mono

Copy quality

Clean the scanner glass

Adjust the lighter/darker contrast setting

Adjust the default copy quality

Adjust the lighter/darker setting for the current job

Define custom copy settings

Change the default media-size setting

Copy onto media of different types and sizes

Print or copy edge-to-edge

Change the default media-type setting

Restore the copy-settings defaults

Copy a book photo card models only

Copy photos

Press Start Copy

Set the multiple-page flatbed copy setting

Copy mixed-size originals

Duplex two-sided copy jobs

Copy two-sided documents manually

Enww

Color for Windows

Manual color adjustment

Manage color

Automatic

Print in Grayscale

Setting description Setting options

Color themes

Neutral Grays

Edge Control

Match colors using the HP Basic Color Match tool

Match colors

Match colors using View Custom Colors

Select Install more software

Advanced color use

Advanced color use

Enww

Scan

Load originals for scanning

Automatic document feeder ADF fax/photo-card model

Use scan

Scan methods

Use the Scan To feature fax/photo-card model

Set up the product Scan Menu button

Set up destinations on the product

Scan from the PC

Add destinations

Scan to a file, e-mail, or software program

Delete destinations

Error Conditions Scanner Failures

Cancel scan

Scan to a memory card

Scan Details

Scan from the HP Scanning software

Cancel scan

Memory card failures

Scanner resolution and color

Scan settings

Scan file format

Resolution and color guidelines

Setting Recommended use

Scan quality

Color

Scan a book photo card models only

Scan a book photo card models only

Scan a photo

Fax fax models only

Fax features

Setup

Install and connect the hardware

Connect to a telephone line

Connect additional devices

Setup for stand-alone fax

Set up fax with a telephone answering machine

Configure fax settings

Use fax set-up wizard on the PC

Use the Fax Set-Up Utility

Use the control panel to set the fax time, date, and header

Manage the phone book

Use of common localized letters in fax headers

Delete phone book

Use phone-book data from other programs

Program Description

Manage speed dials

Special dialing symbols and options

Create and edit speed dials

Manage group-dial entries

Delete speed dials

Create and edit group-dial entries

Delete an individual from a group-dial entry

Set fax polling

Set the sound-volume settings

Change fax settings

Send fax settings

Set autoredial

Set the dial-tone detection

Set the redial-on-busy option

Set light/dark and resolution

Set the redial-on-communication-error option

Set the default light/dark contrast setting

Set resolution settings

Set the default resolution setting

Set the default glass-size setting

Set the resolution for the current fax job

Set the billing-code setting

Set tone-dialing or pulse-dialing

Set billing codes

Use billing codes

Receive fax settings

Use the rings-to-answer setting

Type of telephone line Recommended rings-to-answer setting

Set or change number of rings-to-answer

Set the answer mode

Set fax forwarding

Set up distinctive ring

Use autoreduction for incoming faxes

Create stamp-received faxes

Set the default fax reprint settings

Block or unblock fax numbers

Make an extension telephone available to receive faxes

Use fax

Cancel a fax

Fax software

Delete faxes from memory

Use fax on a DSL, PBX, ISDN, or VoIP system

VoIP

Send a fax

Fax from the flatbed scanner

Fax from the automatic document feeder ADF

Manual dial faxing

Dial manually with the automatic document feeder ADF

Dial manually with the flatbed scanner

Send a fax to a group manually ad hoc faxing

Use speed dials and group-dial entries

Send a fax by using a speed dial

Redial manually

Send a fax by using a group-dial entry

Send a fax from the software Windows XP or Vista

Send a fax from the software

Send a fax from the software Mac OS X

Windows

Send a delayed fax

Send a fax by dialing from a downstream phone

Use access codes, credit cards, or calling cards

Print a stored fax when private receive feature is on

Receive a fax

Reprint a fax

Receive faxes when fax tones are audible on the phone line

Solve fax problems

Fax error messages

Alert and warning message tables

1Alert and warning messages

Fax memory full Canceling recv

Fax memory full Canceling send

Fax recv. error

Fax Send error

No fax answer. Canceled send

Fax storage is full. Unable to answer call

Invalid entry

No Dial Tone

Fax memory is retained when there is a loss of power

Fax logs and reports

Print all fax reports

Print individual fax reports

Set the fax activity log to print automatically

Set the fax error report

Set the fax confirmation report

Set the fax-error-correction mode

Change error correction and fax speed

Perform a fax test

Problems sending faxes

Problem Cause Solution

Change the fax speed

Fax test on

Standard

Problems receiving faxes

Memory and then resumes answering

Performance problems

Photo

Insert a memory card

Insert and remove a memory card

Enww

Change memory card default settings

Print individual photos from the memory card

Print photos directly from the memory card

Print a range of photos from the memory card

Print a memory card thumbnail sheet

Print all of the photos from the memory card

Print and scan photos from a proof sheet

Manage and maintain the product

Description How to print

Information pages

PCL, PCL 6, or PS font list

Event log

Fax reports fax models only

Reports on

View the HP ToolboxFX

HP ToolboxFX

Status

Set up status alerts

Set up e-mail alerts

Alerts

Product information

Fax Receive

Fax

Fax phone book

Enww

Help

Fax send log

Fax receive log

Junk Faxes

Enww

System Settings

Device Information

Paper Handling

Print Quality

Print Density

Color Calibration

Paper Types

Print Settings

System setup

Service

Device polling

Network Settings

PostScript

Features

Embedded Web server

Use HP Web Jetadmin software

Security features

Turn on password protection using the embedded Web server

Turn on password protection from the control panel

Turn on private receive feature

Check supplies status by using the control panel

Check supplies status by using HP ToolboxFX

Manage supplies

Check and order supplies

Store supplies

HP policy on non-HP supplies

HP fraud hotline

Recycle supplies

Replace supplies

Print cartridge

Enww

Enww

Clean the product

Clean the paper path

Clean the paper path from HP ToolboxFX

Clean the paper path from the product control panel

Enww

Enww

Clean the lid backing

Clean the scanner glass

Firmware updates

Clean the exterior

Enww

Problem solve

Problem-solving checklist

Step Verification step Possible problems Solutions Number

Is the power on?

Does Ready appear

Does the product copy?

Does the product receive a fax?

Restore the factory-set defaults

Does the product print from the computer?

Does the product scan to the computer?

Does the device recognize and print from a memory card?

Control-panel messages

1Control-panel messages

Scanner Error

Fan Error, Turn off then on

Error Turn off then on

Canceled copy. Clear document

Comm. error Sender Csid

Device error, press OK

Engine Comm. Error

Engine error, press OK

Install color cartridge

Load Tray 1, Plain Size / Cleaning

Non-HP supply Installed

Fit to Page on flatbed only

Clear jams

Causes of jams

Where to look for jams

Clear jams from the ADF photo card models only

Enww

Enww

Clear jams from the input-tray areas

Clear jams from the output-bin

Avoid repeated jams

Solve image-quality problems

Print problems

Print quality problems

General print quality issues

AaBbCc

HP ToolboxFX on

See HP ToolboxFX on

Service menu item Less paper

Setting. See Control-panel menus

Print media on

Load paper and print media on

Solve issues with color documents

Information pages on page 158. If no

Print-media guidelines

Media-handling problems

See Match colors on

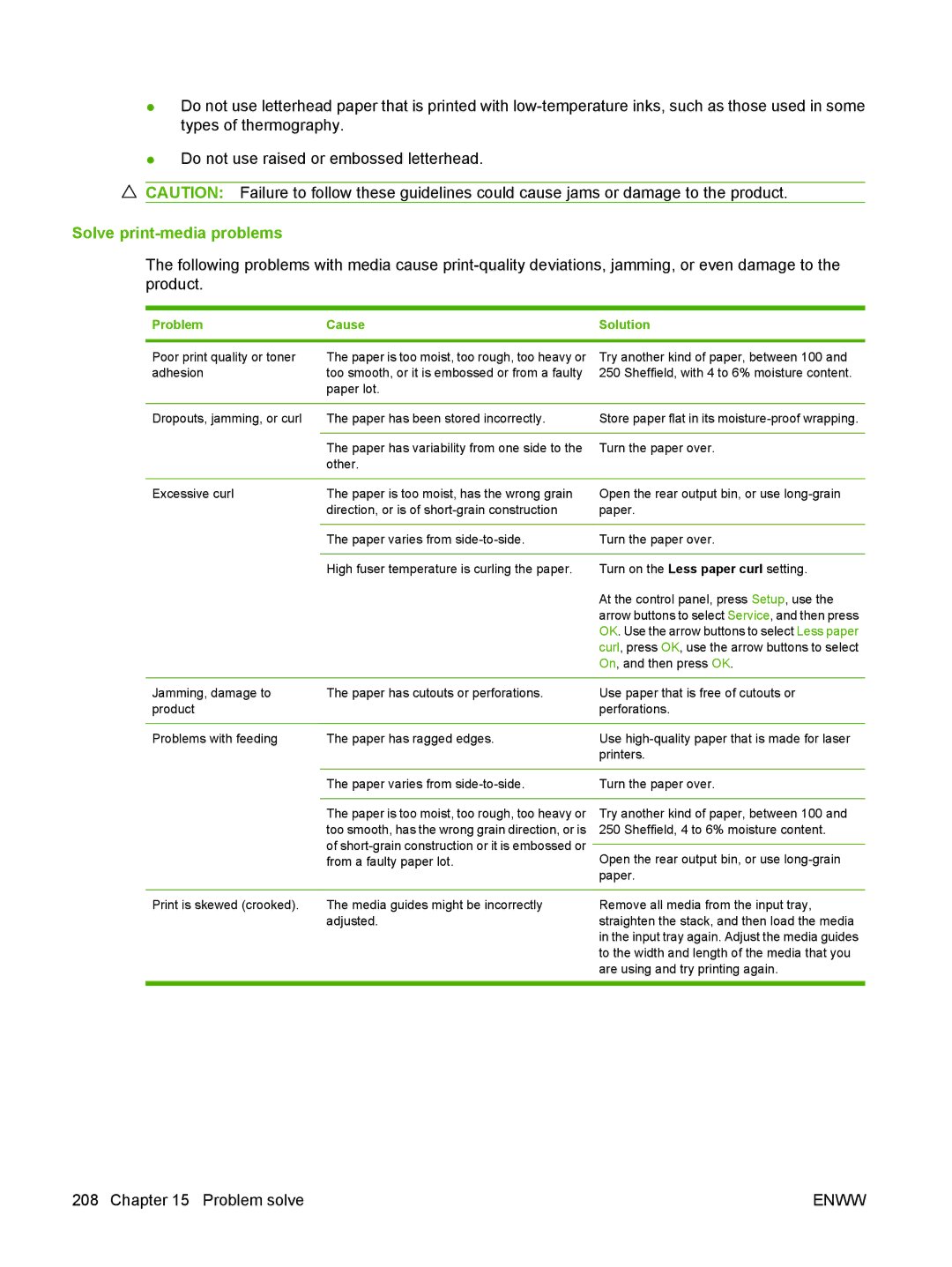

Solve print-media problems

Paper and print media on

Performance problems

Page. See Information pages on

Copy problems

Prevent copy problems

Click Set as Default Printer

Open the Printers or Printers and Faxes

Image problems

See Clean the product on

See Paper and print media on

Cartridge on

Paper varies from side-to-side Turn the paper over

See Load paper and print media

Side to be scanned facing up

Scan problems

Solve scanned-image problems

Problem Cause

Resolution and color on

Be jammed. See Clear jams from the ADF

Photo card models only on

Prevent scan-quality problems

Scan-quality problems

Solve scan-quality problems

Are plugged in securely

Fax problems

Print-quality checklist

Manage and configure printer drivers

Temporarily change print-quality settings

Solve direct-connection problems

Solve connectivity problems

Change print-quality settings for all future jobs

Resolve communication problems with the network

Network problems

Verify that the product is on and online

Enww

Solve software problems

Solve common Windows problems

Solve common Macintosh problems

2Problems with Mac OS X v10.3 and Mac OS X

Name, IP address, or Rendezvous or Bonjour host name

Solve PostScript PS errors

Software troubleshooting

Hardware troubleshooting

Issue Cause Solution

3PS errors

Supplies and accessories

Order parts, accessories, and supplies

Order through service or support providers

Order directly from HP

Order directly through the HP ToolboxFX software

Cable and interface accessories

Part numbers

Supplies

User-replaceable parts

Enww

Service and support

Hewlett-Packard limited warranty statement

Customer self repair warranty service

Print cartridge limited warranty statement

Customer support

Repacking the device

To repack the device

Enww

Specifications

Electrical specifications

Physical specifications

Power consumption

Environmental specifications

Table C-4Environmental specifications1

Acoustic emissions

Table C-5Acoustic emissions

Enww

Regulatory information

FCC regulations

Environmental product stewardship program

Plastics

HP LaserJet print supplies

Return and recycling instructions

United States and Puerto Rico

Paper

Material restrictions

Non-US returns

HP Color LaserJet CM1312 MFP Series

Material Safety Data Sheet Msds For more information

Telephone Consumer Protection Act United States

Additional statements for telecom fax products

IC CS-03 requirements

Additional statements for telecom fax products

Declaration of conformity

HP LaserJet CM1312

HP LaserJet CM1312nfi

Declaration of Conformity

Declaration of conformity

Laser safety

Country/region specific statements

Canadian DOC regulations

EMI statement Korea Laser statement for Finland

Substances table China

六价 铬 CrVI 溴溴 苯 PBB

Enww

Index

ADF

Enww

Enww

Enww

Printing directly from the memory

Enww

Unix

TCP/IP

Msds

Enww

Page

CC430-90975* *CC430-90975