Indoor Units

Model No Outdoor Units

…In a Room

For safe installation and trouble-free operation, you must

…In Moist or Uneven Locations

…In an Area with High Winds

Check of Density Limit

Precautions for Installation Using New Refrigerant

Configuration and characteristics of cylinders

Contents

Tentative

Model No

Specifications Unit Specifications Way Cassette Type

Indoor Unit 36PU1U6 Outdoor Unit 36PE1U6

Indoor Unit 42PU1U6 Outdoor Unit 42PE1U6

Indoor Unit 26PU1U6 Outdoor Unit

Indoor Unit 36PU1U6 Outdoor Unit 36PS1U6

Indoor Unit 42PU1U6 Outdoor Unit 42PS1U6

Data Subject to Change Without Notice

Specifications Unit Specifications Wall Mounted Type

Indoor Unit 26PK1U6 Outdoor Unit

Performance

Specifications Unit Specifications Ceiling Type

Indoor Unit 36PT1U6 Outdoor Unit

Indoor Unit 42PT1U6 Outdoor Unit

Indoor Unit 26PT1U6 Outdoor Unit 26PS1U6

17˚F BTU / h Moisture removal High Pints / h

Indoor Unit 42PT1U6 Outdoor Unit 42PS1U6

Net weight Lbs. kg 128 Shipping weight 148 Shipping volume

Specifications Unit Specifications Low Silhouette Duct Type

Indoor Unit 36PF1U6 Outdoor Unit 36PE1U6

RCZ-RTC2

CZ-RWSC1U

Fan motor

Major Component Specifications Indoor Unit

Model No 36PU1U6 Source

Model No 42PU1U6 Source

Model No 26PK1U6 Source

Model No 26PT1U6 Source

Model No 36PT1U6 Source

Model No 42PT1U6 Source

Model No 26PF1U6 Source

Model No 36PF1U6 Source

Compressor

Specifications Major Component Specifications Outdoor Unit

CR-CH4872R Microprocessor

Lbs. kg R410A 7.9

26PS1U6

230V, 40µF

42PS1U6

Model No 26PE1U6, U-26PS1U6

Specifications Other Component Specifications Outdoor Unit

Model No 36PE1U6, U-36PS1U6

Model No 42PE1U6, U-42PS1U6

Ø1/8

Hol

Page

19/32

31/32 12-7/32

Dimension inch

56-25/32 Air outlet duct flange

Thickness more than T1/16 inch

Page

Page

Specifications

Operating Range

Temperature Indoor Air Intake Outdoor Air Intake

Page

Source

Specifications Noise Criterion Curves Way Cassette Type

Specifications Noise Criterion Curves Wall Mounted Type

Specifications Noise Criterion Curves Ceiling Type

Sound

Noise Criterion Curves Low Silhouette Duct Type

Specifications Noise Criterion Curves Outdoor Units

How to read the diagram

Specifications Increasing the Fan Speed

Indoor Fan Performance Type

Type

Air throw distance chart Way Cassette Type

Model 26 Type

Model 36, 42 Type

Specifications Air throw distance chart Wall Mounted Type

Air throw distance chart Ceiling Type

Model 36 Type

Model 42 Type

Outdoor Unit Type Time delay fuse or Circuit capacity

Wiring System Diagrams

How to Connect Wiring to the Terminal For stranded wiring

Installation Instructions

Ashrae

Selecting the Installation Site

Air-Discharge Chamber for Top Discharge

① Air discharge chamber ② Air discharge chamber base

For U-42PES1U6 unit

Direction

42PES1U6 unit

Front and both sides must remain open

25-13/32 25/32

30-5/64 Wind direction

Obstacle to the front of unit

Installation in front-rear rows

Installing the Outdoor Unit

Routing the Tubing and Wiring

Drainage Work

Low Silhouette Ducted Type Way Cassette Type

Preparation for Suspending

Way Cassette Type U1 Type Suspending the Indoor Unit

Placing the Unit Inside the Ceiling

Installing the Drain Piping

Checking the Drainage

Unit body

Before Installing the Ceiling Panel

When Removing the Ceiling Panel for Servicing

Installing the Ceiling Panel

Accessories

Installing the ceiling panel

Selecting and Making a Hole

Trical wiring or conduits are

Located

Hole Dia. inch

Installing the Rear Panel on the Wall

If Wooden Wall

If Block, Brick, Concrete or Similar Type Wall

How to remove the grille

Removing the Grille to Install the Indoor Unit

How to replace the grille

To mount the indoor unit on the rear panel

How to remove the cover plate

Wiring Instructions General Precautions on Wiring

Shaping the Tubing

Installing the Drain Hose

Ceiling Type T1 Type Suspending the Indoor Unit

Hinge Slide toward front side Side panel Unit

Outside

Good Not good

Duct for Fresh Air

Low Silhouette Ducted Type F1 Type

Required Minimum Space for Installation and Service

26PF1U6

36PF1U6

It is important that you use

Enough to support the weight

Extreme care in supporting

Indoor unit inside the ceiling

Their locking nuts face upward

Tighten the hose clamps so

Be careful since the fan will start

When you short the pin on

Indoor control board

To mount the tube cover, use 5/16

Indoor Fan Performance

Increasing the Fan Speed

When Installing the Indoor Unit

Checkpoint Symptom Remark

Checkpoint after installation

Wireless Remote Controller Installation

How to Install Batteries

If Wall-mounted Fixed Position

Room Temperature Sensor Setting

Address Switches

Setting the Model Code

CZ-RWSU1U

Ceiling Type T1 Type Indicator Section Installation

Electrical Wiring

Test Run Switch

How to use the test run setting U1, T1 Types

Alarm

Misoperation Alarm Indicators

Cause of Trouble

Lamp

If Wall mounted Fixed Position

107

Excessive load on

To avoid placing an

Equipment, use this

Function only when

Bright Cause of Trouble

Timer Standby

Will damage the equipment

Wiring procedure

Group control using 2 signal receiving units

Wiring System Diagram for Group Control

Setting method

Test Run Procedure Wall mounted Type K1 Type

Wireless remote controller transmitter

Check Items Before the Test Run

Test run Using the controller For S-26PK1U6

Indicator

Controller

Test OFF

Precautions

26PK1U6

Nos , 2 OFF, No on

Nos , 2, 3 all OFF

Diagnosis Table

Cause

Indoor unit

HOW to Install the Timer Wired Remote Controller

Tube diameter Tightening torque Tube thickness

Never grasp the drain or refrigerant connecting

Precautions for Packed Valve Operation

Insulating the Refrigerant Tubing Tubing Insulation

Tubes arranged together

Taping the Tubes

Finishing the Installation

Air Purging with a Vacuum Pump for Test Run Preparation

Manifold gauge Vacuum pump

Leak Test

Evacuation

Use a cylinder specifically

Designed for use with R410A

Charging Additional Refrigerant

Finishing the Job

R410A

Processes and Functions

Processes and functions Room Temperature Control

Chart Summary and Explanations

Cooling

Processes and functions Heating

Cold Draft Prevention Heating Cycle

Automatic Fan Speed Indoor Unit

Chart Explanations and notes

Current release control

Discharge temperature release control

Outdoor unit fan control

Coil heating control

Overcurrent protection control

Freeze prevention low-temperature release control

Current release value shift control

Heating high-load control

Defrost control

Outdoor Unit Control PCB

Outdoor Unit Control PCB CR-CH4272R

Example of wiring

Method of System Address Setting

Page

Electrical Data

Indoor Units

Page

Electrical data Wall Mounted Type S-26PK1U6

Electrical data Wall Mounted Type S-26PK1U6

Electrical data Ceiling Type S-26PT1U6, S-36PT1U6, S-42PT1U6

Electrical data Ceiling Type S-26PT1U6, S-36PT1U6, S-42PT1U6

Page

Page

Outdoor Units

Outdoor Units

26PS1U6

Outdoor Units

36PE1U6

Outdoor Units

36PS1U6

Outdoor Units

42PE1U6

Outdoor Units

42PS1U6

Outdoor Units

Page

Service Procedures

Contents of remote controller switch alarm display

Service procedures Meaning of Alarm Messages

Wireless

Remarks

Contents Correction

Remote Alarm Judgment condition Clear condition

Alarm

Eeprom

Service procedures Details of Alarm Messages

Alarm P29

MDC trouble

HIC PCB trouble

Alarm P26

HIC-CH4872R HIC-CH2672R

Alarm E31

26, 36 Type

Communications Trouble within unit

Alarm P22

Alarms F04, F06, F07, F08, F12

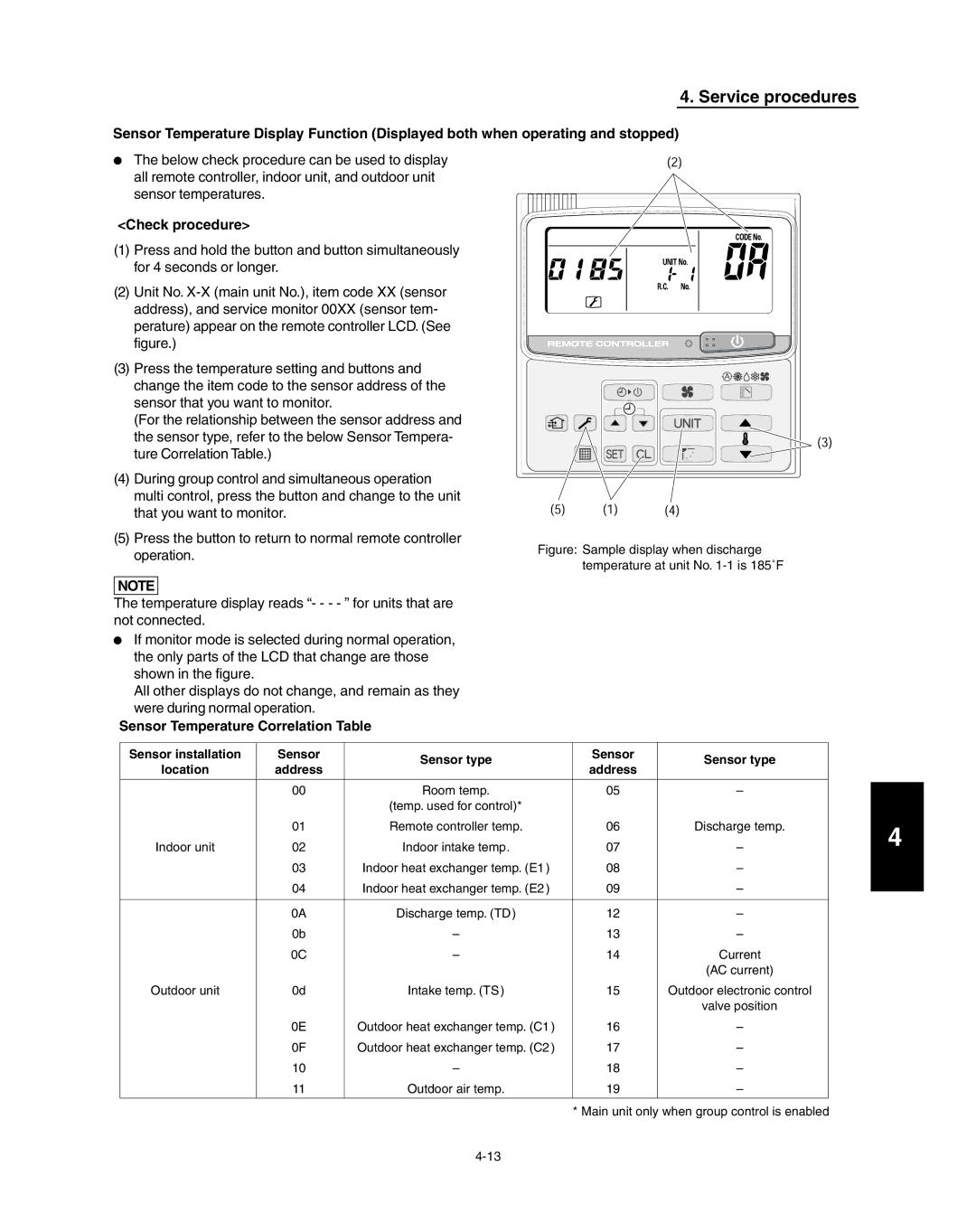

Check procedure

Sensor Temperature Correlation Table

Sensor installation Sensor type Location

Outdoor Air Temp. TO, Intake Temp. TS, Heat

Check Pin

Exchanger Temp. C1 Sensor, Heat Exchanger Temp. C2 Sensor

Discharge Temp. TD Sensors

Outdoor Unit Maintenance Remote Control

Outdoor unit maintenance remote control Overview

Switching between cooling/heating Operation

All units start/stop Operation

All units test run Operation

Sample displays

Item code Display contents

Display for unit Nos

Item code Meaning of Code

Display of first 3 digits Display of last 3 digits

Item code Parameter

List of Item Codes

Outdoor unit maintenance remote control

Figures represent the capacity data for each model

Test RUN

Test run

Preparing for Test Run

Test run U1, K1, T1, F1 Type 6-2. Caution

Items to Check Before the Test Run

Cause

Basic wiring diagram

Test run Examples of Wiring Diagrams

Remote controller crossover wiring for group control

Automatic address setting using the remote controller

Setting the outdoor unit system addresses

2P DIP switch Rotary switch

System address No

Main-sub remote controller control

Connecting 2 remote controllers to control 1 indoor unit

Remote controller setting mode

201201