This manual contains detailed instructions and notes on

Table of Contents

Chapter Extended Functions

Chapter Basic Operations

Iii

Chapter Maintenance

Chapter Appendix

Chapter Troubleshooting

Introduction

Information

All Other Users

Disclaimer of Warranty

For Turkey only

Vii

For Users in India

Viii

Declaration of Conformity

Examples of symbols

Safety Precautions

Hazardous Moving Parts

Safety Precautions

Heater

Handling of the power cable Power supply

Handling of ink

Xii

Xiii

Xiv

Safety interlock

Xvi

Burn injury may result

Xvii

This chapter

Chapter Before Use

Working Environmental Temperature

Where to Install This Machine

Model Width Depth Height Gross weight

Moving This Machine

Front Side of the Machine

Names of Parts and Functions

Rear Side and Right Side of the Machine

Operation Panel

Signs on the power switch

Media sensor

Heater

Cutter blade and slot for cutting

Carriage

Capping station

Pinch rollers and Feed rollers

Your RIP must be compatible with USB

Connecting Cables

Connecting USB2.0 Interface Cable

Connecting the power cable

Inserting ink cartridge

How to assemble ink cartridge

Open the cover of the eco cartridge

Set the ink pack on the eco case

Double coated tape so that it may not move

Firmly fix the ink pack on the eco case with

Attach the cover

Attach the IC chip

About the ink that can be used with this machine

Insert the ink cartridge

Setting orders of ink cartridges

For Ink cartridge lamps

Changing an ink cartridge

About ink expiration date

About cartridge ink end and ink near end

Before Use

Usable sizes of media

Media

Remove the electrostatic sheet

About antistatic sheet

Fix the electrostatic sheet

About antistatic sheet

Chapter Basic Operations

Workflow

Turning the Power on

Turning the Power ON/OFF

Turning the Power OFF

Adjusting the Head Height

Setting a Media

Move the carriage to the Media Transfer Surface

Loosen two screws located at the front

Close the front cover

Fix the carriage

Return the carriage to the station position

Setting a Media

Setting a roll media

Insert the roll media in this machine

Tighten the roll holder fixing screw

Hold the media with the media press gently

Pull out the roll media out

Make the roll media even then lower the clamp lever

Press Key to select Roll

Hold the media with the media guide gently

Prepare for the take-up device

Fix the media on the take-up device. P.2-13

Entering the media remaining amount

Display Screen For entering media remaining

Amount Press Key to enter the media remaining

Take-up device

Setting the torque limiter

Push down the clamp lever

Setting leaf media

Media detection is started

Close the front cover Press Key Key to select Leaf

Changing the printing origin

Typical setting position of printing origin

Local, Press

After determining the origin, press Key

Press To set the temperature Each heater

Changing the Temperature Settings for the Heaters

Press Key to end the setting

Preparing for the Heaters

Changing the Temperature Settings for the Drying Heater

Checking the Heater Temperature

Press Key at the end of confirmation

Press Key three times

Press Key in Local three

Test Feeding

Times Press Key

Press To select ON/OFF

Relationship between head row and test pattern

Test Printing

Press Key in Local

Test Printing

Check the printed test pattern

Check before test

Perform head cleaning depending on the test printing result

Head Cleaning

About head cleaning

Set the media feeding

Setting Feed Correction

Set a media

Press Key to print a correction pattern

Press Key several times to end the setting

Performing the station maintenance without key

Correcting Media-feeding during Printing

Press Key in the Remote

Example of a Drop Position correct Printed Pattern

Press To select the resolution

Press Key to start pattern printing

Press To correct the dot position of Pattern

Repeat

Performing to correct the dot position without key

Next test pattern is printed

Checking the Status of Waste Ink Bottle

Printing Data

Checking the Status of Ink Cartridges

Starting a Printing Operation

Setting a Media Checking the Heater Temperature

Transmit data to be printed from the PC

Start printing

Deleting Received Data Data Clear

Stopping a printing operation halfway

Behavior after printing has been completed

Drying Feed

When INK END error occurs while printing

When Near END error occurs while printing

Cutting a media

Press To specify the cutting position

Printing Data

Page

Chapter Extended Functions

List of Functions

About default Host function

Function name Set value Default

When you set this to on or Host

Setting Logical Seek

Movement of heads when Logical seek is OFF

Movement of heads when Logical seek is on

Press To set drying time for scanning

Setting Drying Time

Press To select Drying Time

Press To select Margin

Setting Margins

Press To set the left margins

Press To set the right margins

Press To change print speed

Press To select Maps

Press To set ON/OFF

Press To select Auto Cleaning

Setting Auto Cleaning

Press To set a cleaning interval

Press To set a cleaning type

Press To select types

Press To select Interval Wiping

Press Key To set levels, and press

Press To set intervals, and press Key

Press To select an item for setting

Other Settings

Press Key To select the setting value

Set value is retained even when the power is turned OFF

Set value Default Meaning

Machine Settings

Press To select Machine Setup

Setting a Auto Power-off

Press To set time to turn OFF the power

Press Key twice

Press To select Media Remain

Setting the Display of Media Residual

Display is turned to on

Display is turned to OFF

Printing the Remaining Amount of a Media

Press To select Time

Setting Time

Press To enter time

Year/Month/Day/Time selectingby

Setting Units

Press To select KEY Buzzer

Setting a KEY Buzzer

Key several times to end the setting

Press To select Language

Setting a Language

Initial setting screed is displayed. LANGUAGE/TIME

Initializing the Settings

Already configured settings are initialized

Displaying the Information

Confirming Machine Information

Press To select Information

Press To select Usage

FILTERwhite

Print Length Print Area

Displaying the Information of this machine

Check such as the machine version information

Press To select a type of information

Information is displayed sequentially with Key

Page

Chapter Maintenance

About Cleaning Fluid

Maintenance

Precautions for Maintenance

Cleaning of after heater cover and pre heater cover

Cleaning the Exterior Surfaces

Cleaning the Media Transfer Surface

Cleaning the Media Holder

Cleaning the Media Sensor

Backside of the machine

Media sensor

Press MAINT. key in Local

Cleaning the Wiper and Cap

Press To select Station Maint

Station.Otherwise, you may get ink in your eyes

Remove the wiper

Open the right maintenance cover cover then

Kimwipe

Take out the wiper and remove ink blot etc. with a

Clean the area around the wiper

Clean the wiper slider

Set the wiper at the original position

Space between the wiper slider and ink guard W

Washing the Ink Discharge Passage Disway Wash

Performing the station maintenance without MAINT. key

Open the right maintenance cover

When the Machine Is Not Used for a Long Time Custody Wash

Close the right maintenance cover and press

Fill up the cap with Cleaning Fluid for maintenance.

Press To select Custody Wash

Clean the wiper and the bracket

Carriage moves onto the Media Transfer Surface

Close the right maintenance cover and press Key

Press To set the time for the Cleaning Fluid

Fill up the cap with Cleaning Fluid for maintenance .

To be left as it is

Open the left maintenance cover

Close the left maintenance cover then press

Cleaning the Head and the Area around It every day

Insert a new absorber

Open the rght maintenance cover then Remove the absorber

After its initial operation, the machine returns to

Close the right maintenance cover then press Key

Washing nozzle surface

Washing of Head nozzle

Press To select Nozzle Wash

Cap rubber. Wipe off so that Cleaning Fluid for

Close the right maintenance cover then press

Fill up the cap with Cleaning Fluid for Maintenance .

Press To select Head Maint

Washing nozzle surface

Close the left maintenance cover then press Key

Immerse Wiper for CR in Maintenance kit

Perform head cleaning Perform test printing

Wipe the nozzle surface from the rear of the main

Select the Nozzle line that needs Nozzle Recovery

Select Nozzle Recovery of the maintenance menu

Select the Print by pressing Key. Then Press

By pressing Key. Then press

Recovery State

Recovery and then press Key

Select the Reset by pressing Key

Reset the set value

Select the Nozzle line that needs clear the setting

Select the Check by pressing Key

Select Auto MAINT. of the maintenance menu

Setting the Refreshing Intervals

Press To set the refreshing interval

Function name Descriptions

Press To select Cleaning

Setting the Cleaning Intervals

Cleaning operation

Press To select a cleaning type

Cleaning type selection screen appears

Press To select CLEANINGWhite

Press To set the interval between each

Set value NORMAL, SOFT, Hard

Replacing consumables

Open the rght maintenance cover then remove

Replacing the wiper

Wiper

Confirmation Message in Local

If a Waste Ink Bottle Confirmation Message Appears

Message on the right is displayed

Check the state of the waste ink bottle

Replace the waste ink bottle with another

Close the waste ink bottle guard Press Key

Replacing the Cutter Blade

Screw

Replace the cutter unit by the carriage

Cutter unit

Screen returns to

Replacing the white ink filter

When white ink filter becomes required to be replaced

When white ink filter replacing time message is displayed

Replace the white ink filter

Open the W filter maintenance cover

Turn OFF the power of the printer

Attach the W filter maintenance cover

Replacing the white ink filter

Filling the white ink

Display

Press Key and show Damper Select

Press Key and select the damper

Ykww

Ink

Close the right maintenance cover Press Key

Press Key and perform air purge

Clearing white ink filter used days

Select Usage of the maintenance menu

Press Key five times, display the used

Number of days of Filter White

Page

Chapter Troubleshooting

Power does not turn on

Troubleshooting

Machine does not start printing

Yes

Is a recommended media used ?

Media get jammed / media is soiled

Image quality is poor

Heat or Constant LED does not light up

Phenomenon Measures

Colors in the printed image appear

Displaying the description of ink cartridge trouble

Nozzle is clogged

Ink cartridge warning appears

Select the damper to maintenance

When Error 618 to 61b occur

Select Damper of the maintenance menu

Select AIR PG of the maintenance menu

When nozzle missing occurs due to ink mixture or aeration

Start air purge by pressing Key

Select the damper to air purge

Close the port

Terminate air purge by pressing Key

Start pushing ink out

Select White MAINT. of the maintenance menu

Regular maintenance of white ink

When the feeding media is loosened and reached to the floor

When media heaves up at feeding

Media feeding

Ing status

Message displayed in Local

Errors when performing operations

Been nearly used up

Ink Error

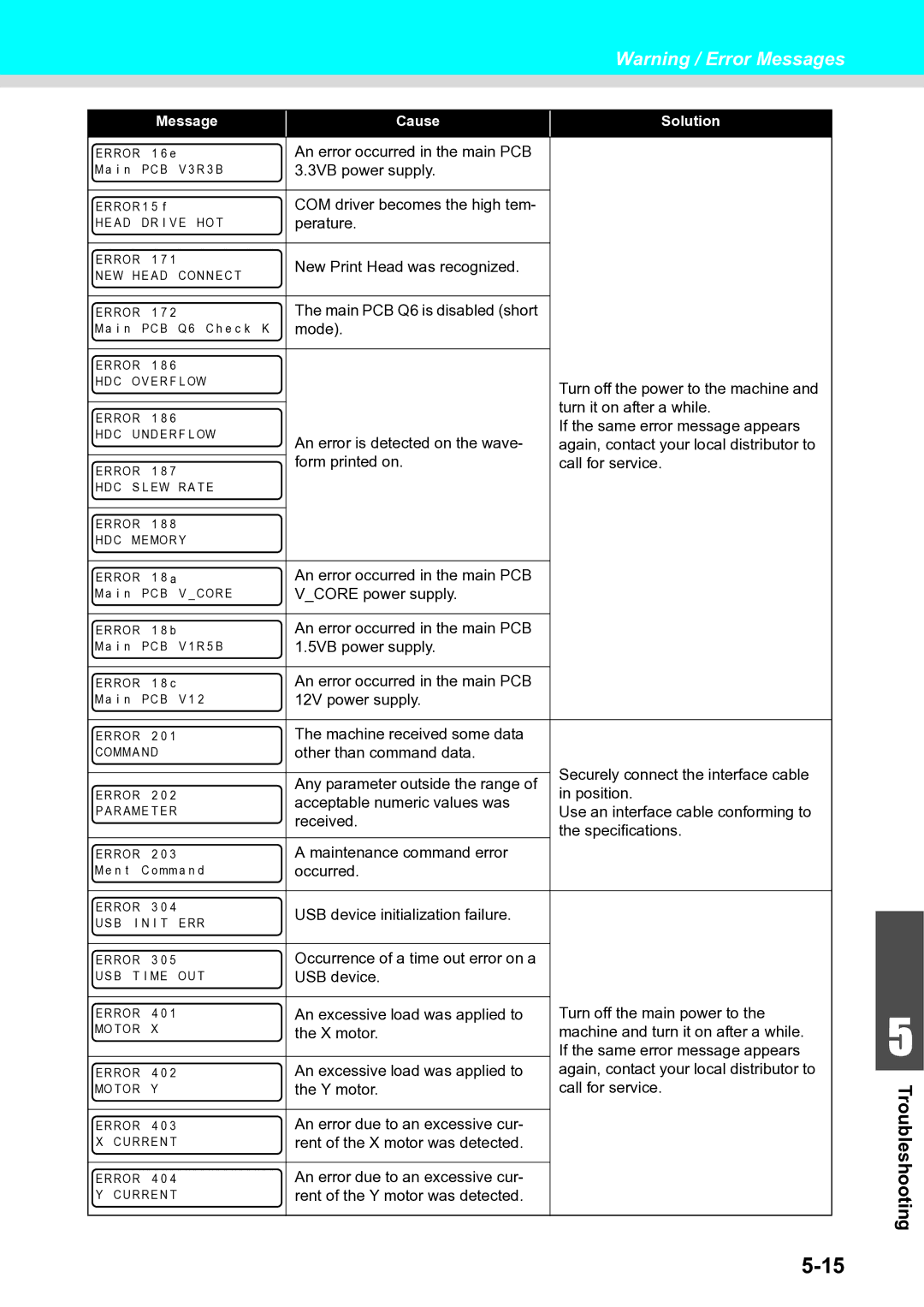

Error messages

3VB power supply

Media jam occurs Remove the media and reset it

System Halt

Page

Chapter Appendix

Machine specifications

Specifications

Specifications

Ink specifications

Product name Product code

List of consumables

Sheet for inquiry

To P.6-8

Function Flowchart

Function Flowchart

From P.6-6

When there is no recovery, it is not displayed

Setup Maintenance Machine SET

S T I N T S T a R T

To P.6-12 To P.6-16 To P.6-20

Setup

Print end

From P.6-12

Displayed when Manual is set

To P.6-18

To Local after initializing

Displayed on Cleaning

From P.6-16

P E Norma L

NE S E T U P

Function Flowchart

EN GB EN US EN AU