890USE17700

Advantys STB

890USE17700 April

Table of Contents

STB NIP 2212 Web Server

IP Parameters

Advanced Configuration Features

Data Exchange

Connection Example

890USE17700 April

Safety Information

Procedure

Important Information

Schneider Electric. All Rights Reserved

About the Book

At a Glance

Who Should Use This Manual?

Title of Documentation Reference Number

Validity Note Related Documents

Introduction

Introduction Whats in this Chapter?

Topic

Network

What Is a Network Interface Module?

Purpose

Fieldbus

Introduction

Structural

Primary

What Is Advantys STB?

Introduction

Island Bus I/O

Segment

Extension

Segments

Island bus can support as many as six extension segments

Modules

Preferred

Length

Standard

CANopen

Devices

STB NIP 2212 Product Overview

Introduction

TCP/IP

Ethernet Communications and Connectivity

Introduction

STB NIP 2212 NIM

External Features of the STB NIP

Features NIM operations are located

Summary

Server, p

Feature Function

Island’s Logic Power Bus, p to the NIM

An RJ-45 See STB NIP 2212 Network Interface, p

Ethernet Port

STB NIP 2212 Network Interface

Fieldbus interface is also called the Ethernet port

Used to connect the STB NIP 2212 to the Ethernet baseband

Connector

Communications

Cable

Represents the ones digit

Rotary Switches

Physical

Description

Valid IP Address

Settings

Ethernet LAN

LED Indicators

Front bezel

Ethernet LAN and the Ethernet port are healthy and alive

ERR red

Ethernet Communications LEDs

Advantys STB Communications LEDs

Label Pattern Meaning

Configuration, p error

Flap on the bottom front of the NIM

Advantys configuration software or an HMI panel

Parameter Valid Values Factory Default Settings

CFG Interface

Parameter Description

Power Supply Interface

Male two-pin connector illustrated below

Located at the bottom left of the module

Connectors

Use either

Right

Improper Galvanic Isolation

Logic Power

Power

External Source

Flow Power and sends it across the primary segment

Logic Power

Improper Galvanic Isolation

NIM PDM

Suggested

TSX SUP 26 W, TSX SUP 1021 53 W, TSX SUP 1051 120 W, or

Telemecanique and, in the United States, from Square D

General Specifications

Module Specifications

Http

STB NIP 2212 NIM

Configuring the Island Bus

Bus Address

Auto-Addressing

Exchange and require island bus addresses

About the Island

Module Physical Location Island Bus Address

An Example

Bus Location

Customizing a

Auto-Configuration

Configuration

About Auto

Installing the STB XMP 4440 Optional Removable Memory Card

Loss of CONFIGURATION-MEMORY Card Damage or

Contamination

Installing the Card

Use the following procedure to install the card

Step

Step Action Open the card drawer

Data are ignored

Edit Mode

New island is in edit mode

Overwritten

Ration Scenarios

Reconfigu

Configuring

Initial

Edit mode

RST Button

Description, p , and behind the same hinged cover

RST button See The RST Button, p causes the island bus to

Unintended Equipment OPERATION/CONFIGURATION Data

Configuration Function to configure your island Scenarios

RST Functionality

With Factory

Default Values

Overwriting

Flash Memory

Configuring the Island Bus

IP Parameters

Assigned by an Internet server

MAC-based default IP address

How the STB NIP 2212 Obtains IP Parameters

Address. The IP address can be

Control MAC

Media Access

Deriving an

IP Address from

Example

Configured

MAC-Based

IP Address

IP Address Assignment Process

Determining

IP Address Checks to determine an IP address

Priorities

Internal positions See Rotary Switches, p

Formats. Ethernet II is the default

Software

Section Topic

STB NIP 2212 Web Server

Introduction Whats in this Section?

Introduction to the Embedded Web Server

About the Embedded Web Server

Use the following steps to access the STB NIP 2212 web site

Accessing STB NIP Web Site

Properties Web

STB NIP 2212 is configured

Properties Web

Sample

Web Server Configuration Options

Is linked to a menu option

Configuration Web

Configuration menu appears in the following figure

Configuration Options Accessing Menu

Configuring an IP Address for the STB NIP

Configured IP address is set up on the Configured IP web

Configured IP Web

IP Parameters Using Command Buttons

Position See Physical Description, p

Assigning a Configured IP Address to the STB NIP

Reboot Option, p

Step Action Comment

Configured IP Web Page, p opens

Restoring Default Parameters from the Web

About

Reboot Option

Field Name Description

Configuring Master Controllers

Controller Web

Setting Up Master Controllers for the Island

Master Configurator Web

Field Legal Values Description

Fields on the Master Configurator Web

Configuring a Master Configurator for the Island

Master Configurator Web Page, p

Configurator Web

Role Name Web

Configuring a Role Name

Three numeric characters, e.g., STBNIP2212002

Sample Role Name web page is shown below

Server-Assigned IP Addresses, p

Configuring a Role Name

Name

Default IP parameters. Use the following steps

Web Server Security

Web Access Password Protection

Default User

Password

STB NIP 2212 Web Server

Setting Up Web Access Login

Navigate to your url http//configured IP address

Properties Web Page, p is

Write protection for your web site is Restored

Configuration Password Protection

Introduction Set Configuration Password Procedure

See Configuring a Role Name, p

Passwords Site, and vice versa

Synchronizing

Advantys

Web Server Diagnostic Options

Menu Accessing Diagnostics

Diagnostics Web

Diagnostics

Diagnostics menu appears in the following figure

Ethernet Statistics

Design

Using Command Buttons

STB NIP 2212 Registers Web

By their Modbus register addresses

STB NIP 2212 Web Server

Modules can be represented on the I/O Data Values web

Data Values Web

Processes

Modules STB DDI 3610s and/or STB DDO 3600s, STB AVI 1270s

Values Web

Island Configuration Web

Configuration Web

Sample Island

Island Parameters Web

Reported on the Error Log web

Error Log Web

Error Log

Operations

Following table

Snmp Services

Snmp Device Management

Snmp PDU

Snmp manager can read the MIB objects for your

Configure Snmp Web

Introduction Fields on the Configure Snmp Web

Purpose Field Name Description

106

Schneider

About the Schneider Private MIBs

Information Base

MIB

Transparent

Factory Ethernet

TFE Subtree

TFE MIB

Service Description

Transparent Factory Ethernet TFE MIB Subtree

Transparent Factory Ethernet

Port502 MIB

Objects and OIDs used by a TFE service

Service Indication for Port Available Values

Port502 Messaging Subtree

Service Indication Available Values

Web MIB Subtree

Activity

Introduction Equipment Profiles MIB Subtree

Service Description Comment

Indicators, p

Equipment Profiles Subtree

Snmp agent

114

Data Exchange

Data Exchange with the STB NIP

Data Exchange

Process

Input modules or writes to the output modules

Data and Status

Objects

Types

Model Module Type

I/O modules have the following island bus addresses

119

Analog output module uses two contiguous registers

PDM short

Short in group

STB DDO 3600 status

Data Exchange Register

On the STB NIP

Reading Diagnostic Data

Are described below

Master Devices

Island

Status

Condition

127

Register

Memory. Each bit represents one configured location

Node

Associated location

130

Queued for the associated module

Emergency

Messages

Modules on the island. Each bit represents a module

132

High byte-all Advantys STB NIMs

Frame

Modbus Commands Supported by the STB NIP

Modbus

Message Data

Ethernet Statistics, p

List of Supported Commands

Issued, and the statistics are retrieved

Statistics

Word No. in Buffer Description Comment

Displayed as byte codes in hexadecimal format

Modbus Error Codes

General Error Codes

Error Code Error Type Description

138

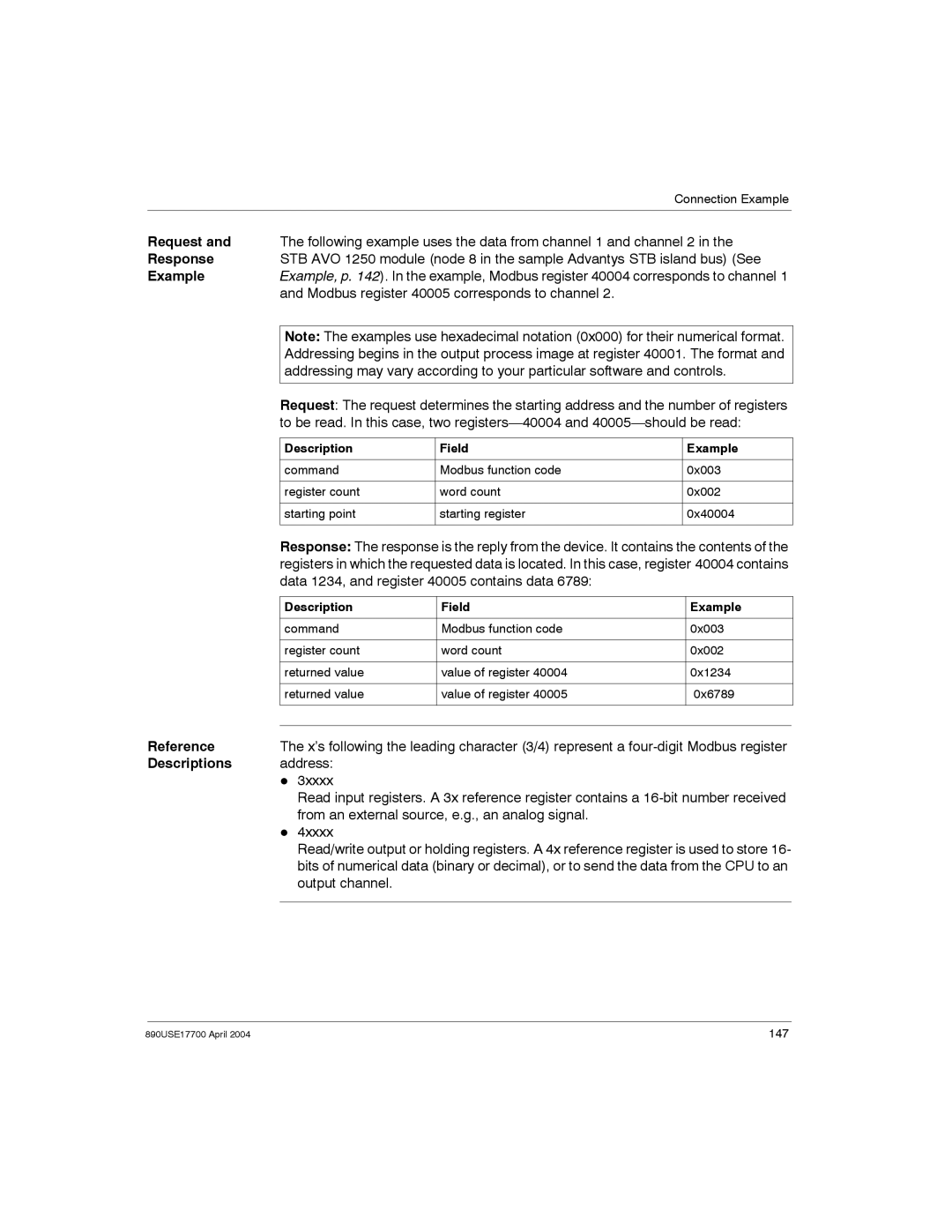

Connection Example

TCP/IP is an open protocol

Overview

Network Interface, p

Network Architecture

Type of Connection Cabling Guidelines

By Schneider Electric

Sample Configuration

Model Module Type Module’s Island Bus Address

Configuration

N3 status

AVI 1250 channel 2 status

45407

AVI 1270 channel 2 status 45408

AVI 1250 channel 1 status 45409

Modbus Functions Supported by the STB NIP

Descriptions

Request

Response

Reference

Statistics, p

Indicate an error condition

List of Supported Function Codes Their Descriptions

Modbus over TCP/IP Data Exchange

Advanced Configuration Features

Information

STB NIP 2212 Configurable Parameters

Accessing Configurable Parameters

General

151

Assigning

Reserving Data

Sizes

Must reserve space for that data. To reserve data sizes

Configuring Mandatory Modules

Specifying

Mandatory

CONFIGURATION-RST Button While Recovering from

Unintended Equipment OPERATION/LOSS

Mandatory Stop

Prioritizing a Module

Than other island modules

Limitations

Unexpected Output Operation

What Is a Reflex Action?

How Reflex

Actions Behave

Action

Configuring a

Reflex Action

Inputs to a Reflex

Reflex Action Result Action Module Type

First nested action

Nesting

Block is an operational input to the second block

Table above

On an action module

Number of Reflex

Blocks on an

Blocks

Island Fallback Scenarios

Fallback

Heartbeat

Fallback States

For Reflex

Functions

When you attempt to save it

Saving Configuration Data

Protection

Protecting Configuration Data

Feature

Characteristics

Displayed as the rightmost bit in the register

Modbus View of the Island’s Data Image

Registers

Their Bit

Block

167

Island’s Process Image Blocks

Output Data

Process Image

Capabilities

Read/Write

HMI Panel

HMI Blocks in the Island Data Image

171

172

Glossary

BOS

ARP

CRC

Can

COB

Coms

EMC

DIN

EDS

EIA

Fsdp

EOS

Fedp

Frdp

Devices on the network

Gateway

Program or /hardware that passes data between networks

GlobalID

IEC type 1 input

Base

Scanning

IEC

Interbus

Nema

Energized and open when the coil is energized

Energized and closed when the coil is energized

Contact

NMT

NIM

PDM

PDO

PLC

RTD

Selv

SAP

Scada

SDO

Snmp

Smmps

Stdp

TCP

TFE

Voltage group

UDP

Varistor

Suppress transient voltage surges

Index Numerics

Diagnostics menu

Index

191

192

193

194