12. IO Scanning service

12. 1. Presentation

The IO Scanning service is used to exchange periodic I/O data between:

•A controller or PLC (IO Scanner).

•Devices (IO Scanning servers).

This exchange is usually performed by implicit services, thus avoiding the need to program the controller (PLC). The IO Scanner periodically generates the Read/Write Multiple Registers (23 = 16#17) request.

The IO Scanning service operates if it has been enabled in the PLC and the drive.

The drive parameters assigned to IO Scanning have been selected by default. This assignment can be modified by configuration.

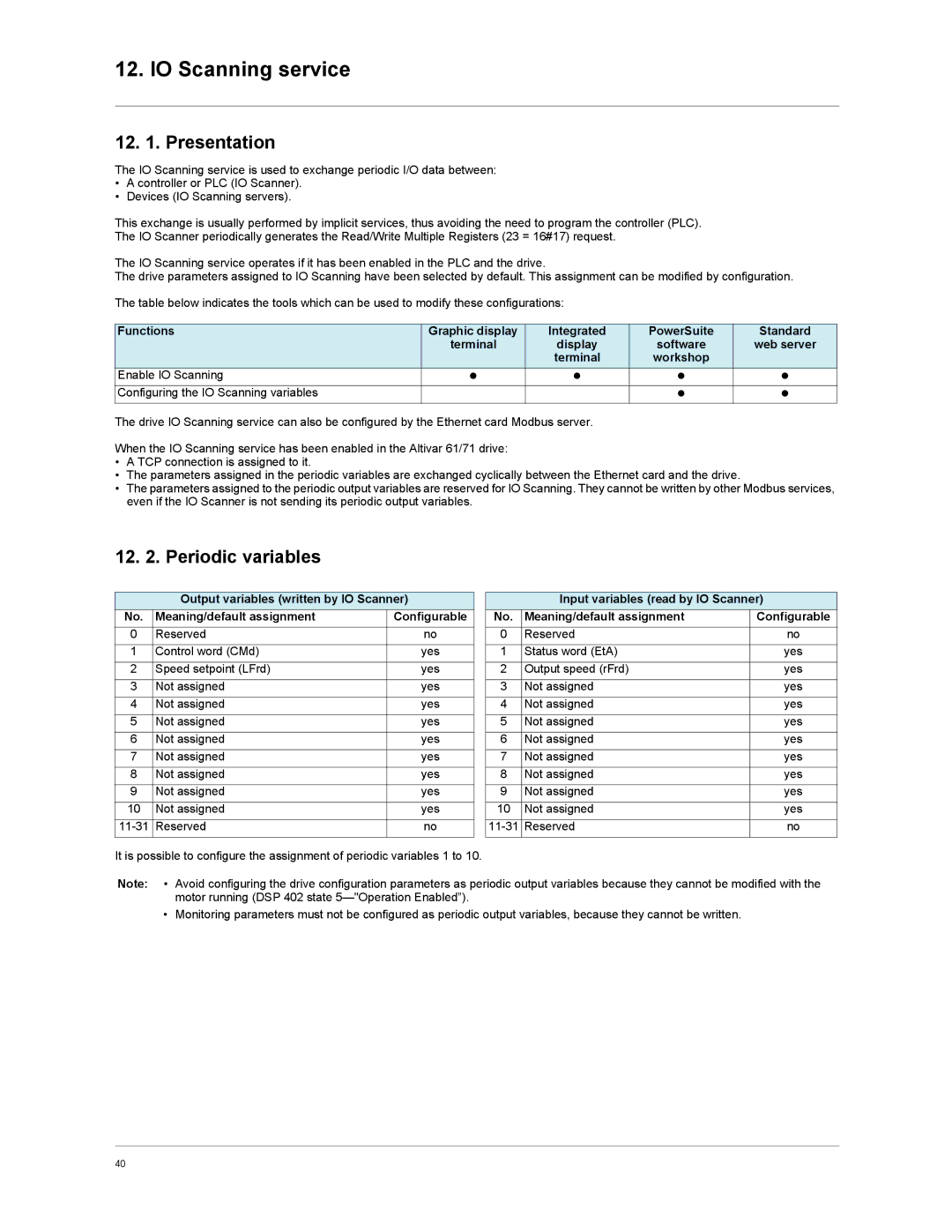

The table below indicates the tools which can be used to modify these configurations:

Functions | Graphic display | Integrated | PowerSuite | Standard |

| terminal | display | software | web server |

|

| terminal | workshop |

|

Enable IO Scanning | p | p | p | p |

Configuring the IO Scanning variables |

|

| p | p |

The drive IO Scanning service can also be configured by the Ethernet card Modbus server.

When the IO Scanning service has been enabled in the Altivar 61/71 drive:

•A TCP connection is assigned to it.

•The parameters assigned in the periodic variables are exchanged cyclically between the Ethernet card and the drive.

•The parameters assigned to the periodic output variables are reserved for IO Scanning. They cannot be written by other Modbus services, even if the IO Scanner is not sending its periodic output variables.

12. 2. Periodic variables

| Output variables (written by IO Scanner) | |

No. | Meaning/default assignment | Configurable |

0 | Reserved | no |

1 | Control word (CMd) | yes |

2 | Speed setpoint (LFrd) | yes |

3 | Not assigned | yes |

4 | Not assigned | yes |

5 | Not assigned | yes |

6 | Not assigned | yes |

7 | Not assigned | yes |

8 | Not assigned | yes |

9 | Not assigned | yes |

10 | Not assigned | yes |

Reserved | no | |

It is possible to configure the assignment of periodic variables 1 to 10.

| Input variables (read by IO Scanner) | |

No. | Meaning/default assignment | Configurable |

0 | Reserved | no |

1 | Status word (EtA) | yes |

2 | Output speed (rFrd) | yes |

3 | Not assigned | yes |

4 | Not assigned | yes |

5 | Not assigned | yes |

6 | Not assigned | yes |

7 | Not assigned | yes |

8 | Not assigned | yes |

9 | Not assigned | yes |

10 | Not assigned | yes |

Reserved | no | |

Note: • Avoid configuring the drive configuration parameters as periodic output variables because they cannot be modified with the motor running (DSP 402 state

• Monitoring parameters must not be configured as periodic output variables, because they cannot be written.

40