Appendix 1 – Isolators

APPENDIX 1

INSTALLATION AND ADJUSTING INSTALLATIONS

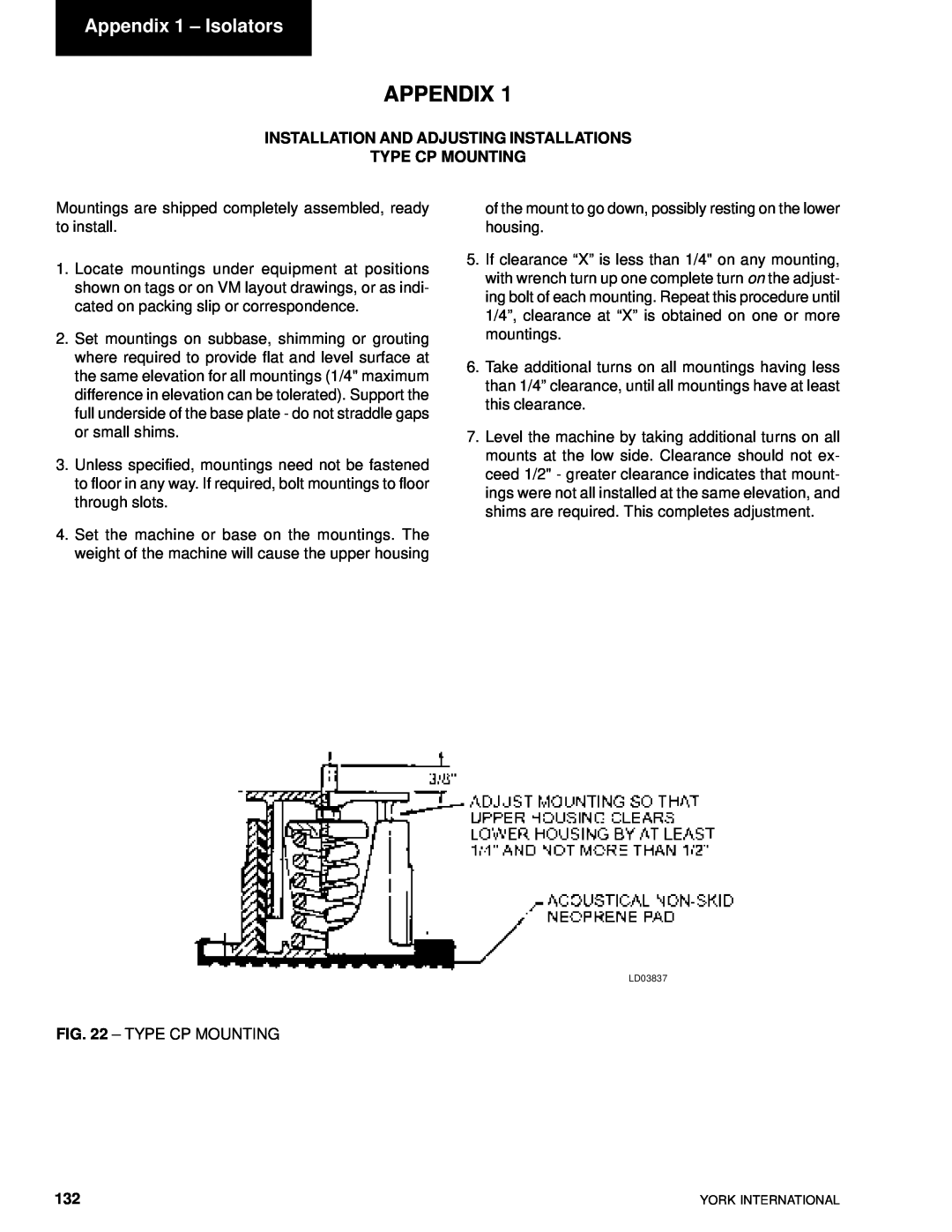

TYPE CP MOUNTING

Mountings are shipped completely assembled, ready to install.

1.Locate mountings under equipment at positions shown on tags or on VM layout drawings, or as indi- cated on packing slip or correspondence.

2.Set mountings on subbase, shimming or grouting where required to provide flat and level surface at the same elevation for all mountings (1/4" maximum difference in elevation can be tolerated). Support the full underside of the base plate - do not straddle gaps or small shims.

3.Unless specified, mountings need not be fastened to floor in any way. If required, bolt mountings to floor through slots.

4.Set the machine or base on the mountings. The weight of the machine will cause the upper housing

of the mount to go down, possibly resting on the lower housing.

5.If clearance “X” is less than 1/4" on any mounting, with wrench turn up one complete turn on the adjust- ing bolt of each mounting. Repeat this procedure until 1/4”, clearance at “X” is obtained on one or more mountings.

6.Take additional turns on all mountings having less than 1/4” clearance, until all mountings have at least this clearance.

7.Level the machine by taking additional turns on all mounts at the low side. Clearance should not ex- ceed 1/2" - greater clearance indicates that mount- ings were not all installed at the same elevation, and shims are required. This completes adjustment.

LD03837

FIG. 22 – TYPE CP MOUNTING

132 | YORK INTERNATIONAL |