FORM

PROBLEM |

| CAUSE | SOLUTION |

|

|

|

|

|

|

| |

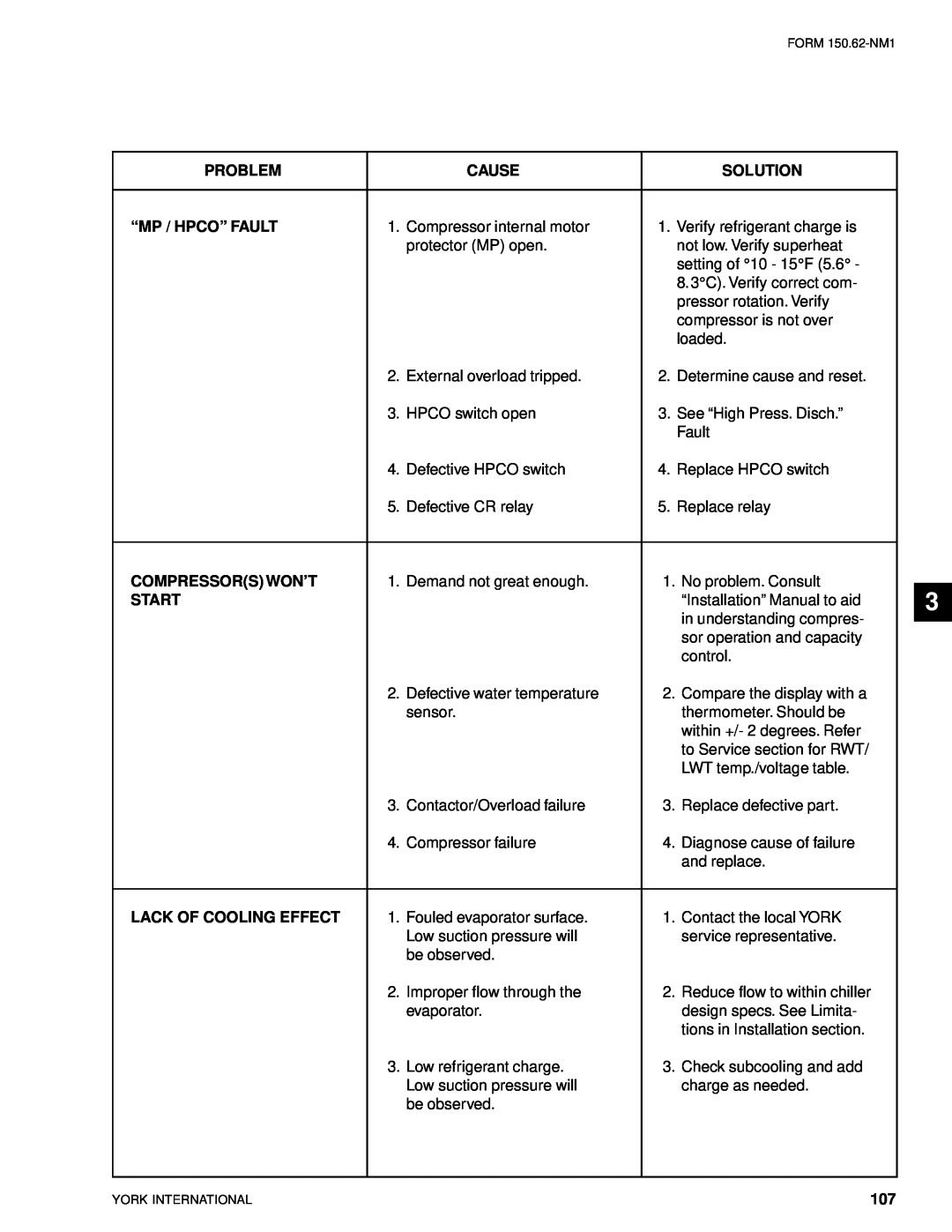

“MP / HPCO” FAULT | 1. Compressor internal motor | 1. Verify refrigerant charge is |

|

| |

|

| protector (MP) open. | not low. Verify superheat |

|

|

|

|

| setting of ° 10 - 15° F (5.6° - |

|

|

|

|

| 8.3°C). Verify correct com- |

|

|

|

|

| pressor rotation. Verify |

|

|

|

|

| compressor is not over |

|

|

|

|

| loaded. |

|

|

| 2. | External overload tripped. | 2. Determine cause and reset. |

|

|

| 3. | HPCO switch open | 3. See “High Press. Disch.” |

|

|

|

|

| Fault |

|

|

| 4. | Defective HPCO switch | 4. Replace HPCO switch |

|

|

| 5. | Defective CR relay | 5. Replace relay |

|

|

|

|

|

|

| |

COMPRESSOR(S) WON’T | 1. Demand not great enough. | 1. No problem. Consult |

|

| |

| 3 | ||||

START |

|

| “Installation” Manual to aid |

| |

|

|

| in understanding compres- |

|

|

|

|

|

|

| |

|

|

| sor operation and capacity |

|

|

|

|

| control. |

|

|

| 2. | Defective water temperature | 2. Compare the display with a |

|

|

|

| sensor. | thermometer. Should be |

|

|

|

|

| within +/- 2 degrees. Refer |

|

|

|

|

| to Service section for RWT/ |

|

|

|

|

| LWT temp./voltage table. |

|

|

| 3. | Contactor/Overload failure | 3. Replace defective part. |

|

|

| 4. | Compressor failure | 4. Diagnose cause of failure |

|

|

|

|

| and replace. |

|

|

|

|

|

|

| |

LACK OF COOLING EFFECT | 1. Fouled evaporator surface. | 1. Contact the local YORK |

|

| |

|

| Low suction pressure will | service representative. |

|

|

|

| be observed. |

|

|

|

| 2. | Improper flow through the | 2. Reduce flow to within chiller |

|

|

|

| evaporator. | design specs. See Limita- |

|

|

|

|

| tions in Installation section. |

|

|

| 3. | Low refrigerant charge. | 3. Check subcooling and add |

|

|

|

| Low suction pressure will | charge as needed. |

|

|

|

| be observed. |

|

|

|

|

|

|

|

|

|

YORK INTERNATIONAL | 107 |