Unit Controls

PUMPDOWN (LLSV) CONTROL

Each system has a Pumpdown feature upon

LOAD LIMITING

Load Limiting is a feature that prevents the unit from loading beyond the desired value. 2 and 4 compressor units can be load limited to 50%. This would allow only 1 compressor per system to run. 3 and 6 compressor units can be load limited to 33% or 66%. The 66% limit would allow up to 2 compressors per system to run, and the 33% limit would allow only 1 compressor per system to run. No other values of limiting are available.

There are two ways to load limit the unit. The first is through remote communication via an ISN.

A second way to load limit the unit is through closing contacts connected to the Load Limit

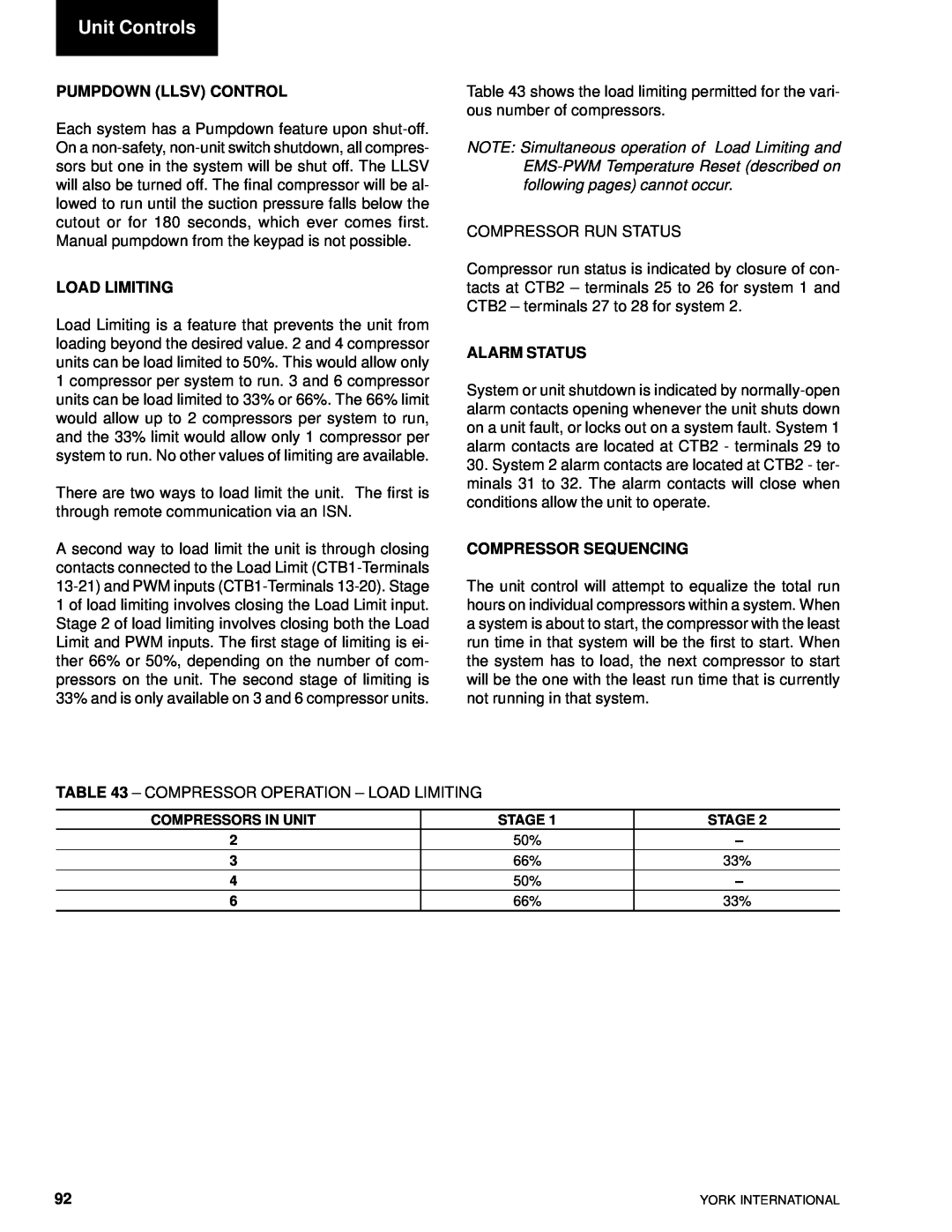

Table 43 shows the load limiting permitted for the vari- ous number of compressors.

NOTE: Simultaneous operation of Load Limiting and

COMPRESSOR RUN STATUS

Compressor run status is indicated by closure of con- tacts at CTB2 – terminals 25 to 26 for system 1 and CTB2 – terminals 27 to 28 for system 2.

ALARM STATUS

System or unit shutdown is indicated by

30.System 2 alarm contacts are located at CTB2 - ter- minals 31 to 32. The alarm contacts will close when conditions allow the unit to operate.

COMPRESSOR SEQUENCING

The unit control will attempt to equalize the total run hours on individual compressors within a system. When a system is about to start, the compressor with the least run time in that system will be the first to start. When the system has to load, the next compressor to start will be the one with the least run time that is currently not running in that system.

TABLE 43 – COMPRESSOR OPERATION – LOAD LIMITING

COMPRESSORS IN UNIT | STAGE 1 | STAGE 2 |

2 | 50% | – |

3 | 66% | 33% |

4 | 50% | – |

6 | 66% | 33% |

92 | YORK INTERNATIONAL |