S Y S | 1 | S Y S | S W I | T C H | O F F |

S Y S | 2 | S Y S | S W I | T C H | O F F |

|

|

|

|

|

|

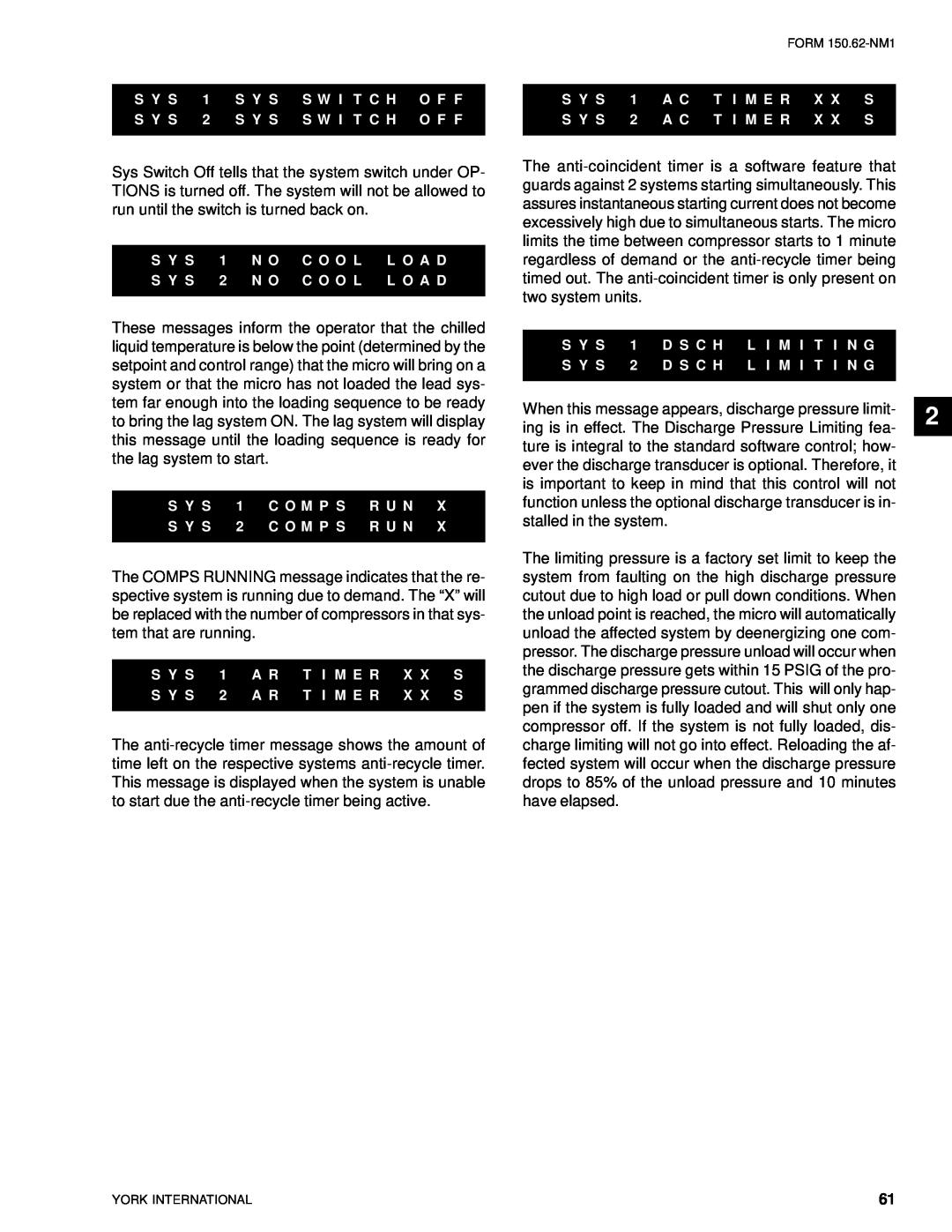

Sys Switch Off tells that the system switch under OP- TIONS is turned off. The system will not be allowed to run until the switch is turned back on.

S Y S | 1 | N O | C O O L | L O A D |

S Y S | 2 | N O | C O O L | L O A D |

|

|

|

|

|

These messages inform the operator that the chilled liquid temperature is below the point (determined by the setpoint and control range) that the micro will bring on a system or that the micro has not loaded the lead sys- tem far enough into the loading sequence to be ready to bring the lag system ON. The lag system will display this message until the loading sequence is ready for the lag system to start.

S Y S | 1 | C O M P S | R U N | X |

S Y S | 2 | C O M P S | R U N | X |

|

|

|

|

|

The COMPS RUNNING message indicates that the re- spective system is running due to demand. The “X” will be replaced with the number of compressors in that sys- tem that are running.

S Y S | 1 | A R | T | I M E R | X X | S |

S Y S | 2 | A R | T | I M E R | X X | S |

|

|

|

|

|

|

|

The

FORM

S Y S | 1 | A C | T | I M E R | X X | S |

S Y S | 2 | A C | T | I M E R | X X | S |

|

|

|

|

|

|

|

The

S Y S | 1 | D S C H | L | I M I | T | I | N G |

S Y S | 2 | D S C H | L | I M I | T | I | N G |

|

|

|

|

|

|

|

|

When this message appears, discharge pressure limit- ing is in effect. The Discharge Pressure Limiting fea- ture is integral to the standard software control; how- ever the discharge transducer is optional. Therefore, it is important to keep in mind that this control will not function unless the optional discharge transducer is in- stalled in the system.

The limiting pressure is a factory set limit to keep the system from faulting on the high discharge pressure cutout due to high load or pull down conditions. When the unload point is reached, the micro will automatically unload the affected system by deenergizing one com- pressor. The discharge pressure unload will occur when the discharge pressure gets within 15 PSIG of the pro- grammed discharge pressure cutout. This will only hap- pen if the system is fully loaded and will shut only one compressor off. If the system is not fully loaded, dis- charge limiting will not go into effect. Reloading the af- fected system will occur when the discharge pressure drops to 85% of the unload pressure and 10 minutes have elapsed.

2

YORK INTERNATIONAL | 61 |