Protect PV.630

Page

Page

Page

Protect PV.630

Operating instructions

AEG Power Solutions GmbH

Table of Contents

Monitoring Systems, Messages and Faults

System Function

Interfaces

Graphical Display and Operation Unit

Information on How to Use these Instructions

Warranty

General Information

Validity

Target Groups

Explanations of Target Groups

Obligations of the Equipment Operator

Handling

Skilled Personnel Skills and Trainings

Storing Instructions

Obligations of skilled personnel

Symbol Meaning

Explanation of Symbols and Safety Instructions

Explanation of Symbols

Safety Instructions

Signal Words Used

Hazard Symbols Used

Symbol Meaning for skilled personnel

Signs Containing Orders for Personal Protective Equipment

Abbreviations

Emergency Procedure e.g. in the Event of a Fire

Safety Awareness

Particular Dangers associated with Photovoltaic Systems

Crystalline silicon cells

Thin-film cells

Lightning protection

Safety Signs and Warning Notices on the Equipment

Safety and Protection Devices for the Equipment

System stop switch

Protective Covers

Residual Hazards

Lockable Equipment Doors

Guard

Electrical Hazards

Risks Due to Moving Parts

Fire-Related Risks

Water in electrical equipment

Risk of injury due to rotating fans

Risks from Maintenance and Repair Work

Risks due to Loss of Control

Important information about equipment documenta- tion

Product Details

Product Description

Appropriate Use

Dimensions and Views

Safety

Nameplate

Inappropriate Use

Standards, Directives and CE Mark

Technology

Operating Elements

System Description

Operating Modes

Individual Operation

Partner Operation

System Function

Description of Sequence Control

OFF Status

Waiting for Feed Conditions Status

Operation Status

Waiting Status

Fault Status

Night Status

Sequence Control During the Course of the Day

Early morning

Day

Evening

Later in the evening

Night

Inverter stack switch-on time

Permissible voltage dip after switching on the stack

Power limit value for shutdown, delay time for shutdown

Sequence Control Parameters

Description of Fan Control General

Fan Control, Cabinet Fan

Cabinet Fan Control Parameters

Fan Control, Inverter Stack Fan

Igbt temperature limit value for switching off the fan

Igbt temperature limit

Parameters of Inverter Stack Fan Control

Insulation Monitoring and Earthing of PV Cells General

Maintenance mode

Operation with Thin-Film Solar Cells

General

Sequence control

Insulation Monitoring in Partner Operation

Insulation Monitoring Parameters

MPP Tracker

Linked Operation

Change of status to linked operation

Single Operation

Change of status to separate operation

Linked Operation in the Event of a Fault

Partner Operation During the Course of the Day

Extended operating mode

Load threshold for connecting the INV

Partner Operation Parameters

Later that morning

Monitoring Systems, Messages and Faults

Parameters of the Extended operating mode

Power rating for normal feed-in capacity

Power rating for increased feed-in capacity

Protect PV.630 Operating Instructions

Table of Faults

Temperature monitoring systems

Can I/O monitoring systems Fault/Message

Unit Monitoring Systems Fault/Message

DC voltage monitoring systems Fault/Message

Interfaces

Communication Interface

Technical Data MultiCom CCC hardware data assembly A29.1

Communication data port 1

Communication data port 2

Communication data port 3

Configuration jumpers

Structure of the MultiCom CCC Interface

Connections

Button

Description of serial interfaces

Port 2 X5 RS485 pin assignment default

Shield connection of the RS485 bus line

Port 3 X4 can pin assignment

Port 2 X5 RS232 pin assignment

Controller Area Network can at

Setting the terminal program

Configuration

Configuration Preparations

Carriage return or Enter key

Configuring the Modbus Protocol

Data protocol configuration

Configuring Modbus Data Transmission

Modbus/JBus data transmission configuration

Structure of the COM Server

COM Server General

Network Connection

Installation of the COM Server

Network Integration Configuration

Configuration of the Virtual COM Port

Structure

Remote Signalling

Technical data

Following default signals are used for remote signalling

Graphical Display and Operation Unit

DOU

Signalling

Acoustic signal generator

Keyboard Operation

LEDs

Possible symbol keys and their function

Start-up

Menu Structure Menu Tree

Main Menu

Operating Display

Operating display Normal operation

Examples of possible displays

Example of operating display

Solar radiation is too low, the inverter is in standby mode

Monthly data t = day 1 31 for the last 12 months

Example of yearly overview

Menu

Status/Measured Values

Blocking

Menu Inverter

Fault History

Settings

Service

Information

Installation and Start-up

80000047963 BAL

Isolating Solar Inverters

Connection Work

Start-up

Safety

General Information

Transport, Storage and Installation

Installation Site Requirements, Operating Area

Packaging

Storage

Air vents on the system 1=supply air, 2=exhaust air

Preparations

Using a Crane to Transport and Install the System

Risk of accident due to suspended loads

Transporting the Equipment

Preparation

Using a Forklift or Lowlift Truck to Transport the System

Risk of accident due to transport with industrial trucks

Transporting a system using industrial truck

Installing, Aligning, Attaching

Bottom attachment 80000047963 BAL

Tightening Torque Values for Screw Connections

Installation without control cabinet doors

Connection Work

System not installed correctly

Power terminals

External Connections

Control/Monitoring terminals

Cables are connected as follows

Start-up

Prerequisites

Before connecting the AC voltage, check

Start-up Preparations

Right bridge block

Medium voltage Switchgear not connected correctly

Connection of AC Voltage

Auxiliary power supply via external circuit

After connecting the DC voltage

Field rotation fault fault message

Other fault indications

Connection of DC Voltage

Isolation Procedure

Isolating Solar Inverters

Maintenance and Servicing

Protect PV.630 Maintenance and Servicing

Fault Messages

General Information

Maintenance and Repair

Scope of the Recommended Measures

Inspection

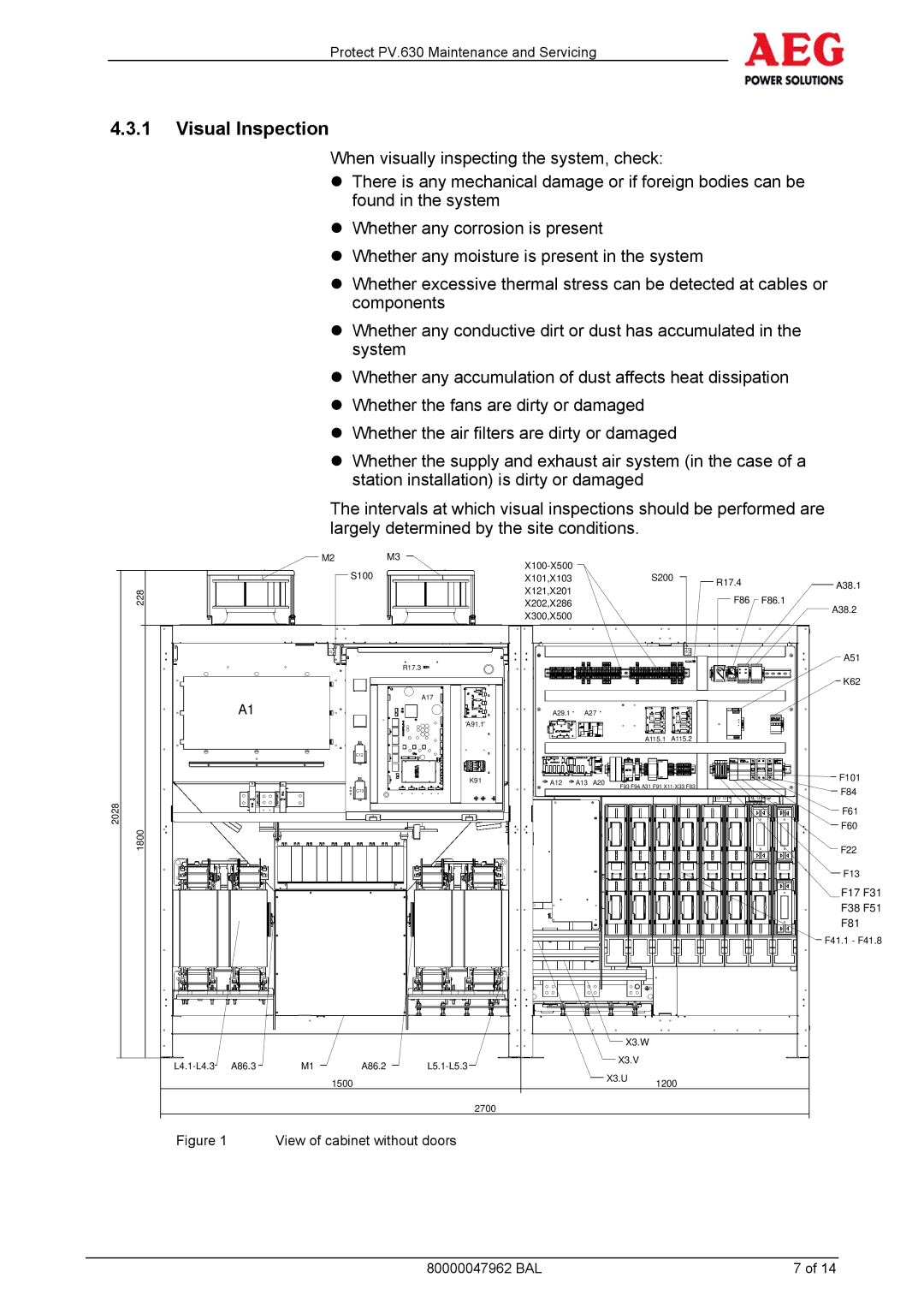

Visual Inspection

View of cabinet without doors 80000047962 BAL

Diagnostic Functions

Reading Out the Memory

Removing Accumulated Dust

Obligation to Keep a Written Record

Functional Test

Isolating Solar Inverters

Cleaning and Checking the Protection Devices

Maintenance

Checking the Monitoring System

System Stop

Additional Work

Repair

Removing the fan

Removing and Installing the Fans

Installing the fan

Power Section

Component

Fault Messages

Spare Parts and Customer Service

Page

Protect PV.630

Page

CEA

Page

X3UVWPE

Page

1000003063

Page

Peinv

Page

F83

Page

A29.1 A27 A20

Page

1000003063 en