Thermal Design Guide for Socket F (1207) Processors | 32800 Rev. 3.00 August 2006 |

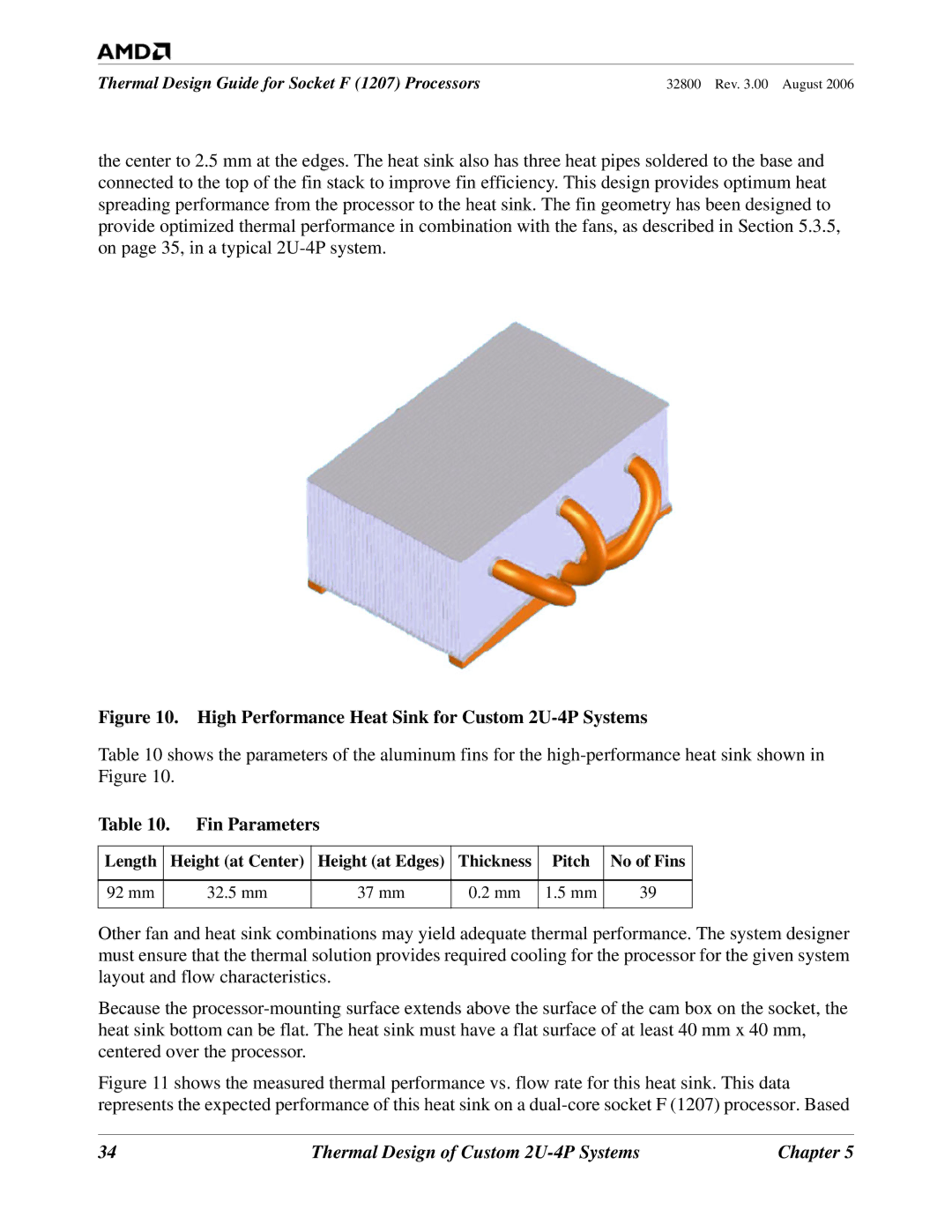

the center to 2.5 mm at the edges. The heat sink also has three heat pipes soldered to the base and connected to the top of the fin stack to improve fin efficiency. This design provides optimum heat spreading performance from the processor to the heat sink. The fin geometry has been designed to provide optimized thermal performance in combination with the fans, as described in Section 5.3.5, on page 35, in a typical

Figure 10. High Performance Heat Sink for Custom 2U-4P Systems

Table 10 shows the parameters of the aluminum fins for the

Table 10. | Fin Parameters |

|

|

| ||

|

|

|

|

|

|

|

Length |

| Height (at Center) | Height (at Edges) | Thickness | Pitch | No of Fins |

|

|

|

|

|

|

|

92 mm |

| 32.5 mm | 37 mm | 0.2 mm | 1.5 mm | 39 |

|

|

|

|

|

|

|

Other fan and heat sink combinations may yield adequate thermal performance. The system designer must ensure that the thermal solution provides required cooling for the processor for the given system layout and flow characteristics.

Because the

Figure 11 shows the measured thermal performance vs. flow rate for this heat sink. This data represents the expected performance of this heat sink on a dual-core socket F (1207) processor. Based

34 | Thermal Design of Custom | Chapter 5 |