RETRIES: (DATA line 3 and 1, FIRST and FINAL dispense)

When FIRST time dispense, (DATA line 3), does not equal FINAL dispense, (DATA line 1), one or more retries have occurred. Retries are evidence of a problem that will also cause percentage errors.

Retries may indicate possible problems; perhaps the hopper ran out of material, or the flow rate is so erratic that the first dispense was short for no good reason. Parameters _RT and _RP determine what shortage error is necessary to force a retry.

FLOW RATE NUMBERS: (DATA line 2)

Check the RATE numbers, (DATA line 2), to determine each dispense device.

In the example above:

In the REGRIND column, 18224 and 976 translate to 1822.4 grams in 4 seconds (244 interrupts = 1 sec), or 455.6 grams per second, typical for a regrind flowing through 3" round or 2"x3" dispense valves.

In the NATURAL column, 19993 and 488 indicate 1999.3 grams in 2 seconds, or 999.6 grams per second flow rate. This is a heavy natural material, not polyethylene. Perhaps Lexan or a glass filled material.

In the COLOR column, 12973 and 31232 indicate 1297.3 grams per 31232 interrupts, or 128 seconds, for a flow rate of 9.99 grams per second. This is a 1 inch auger feeder, from which we would typically expect about 8 grams per second. More recent auger feeders use faster motors delivering about 16 grams per second.

In the ADDITIVE column, 10240 and 31232 indicate a flow rate of 8 grams per second EXACTLY. Since it is exact, and since these two numbers are, in fact, the "default" settings from when the blender was first installed, we know that "Additive" has never been run on this blender, or at least not since the last "CLEAR ALL" was performed.

DATA line 3 dispense weight of 0.0 for additive, and the

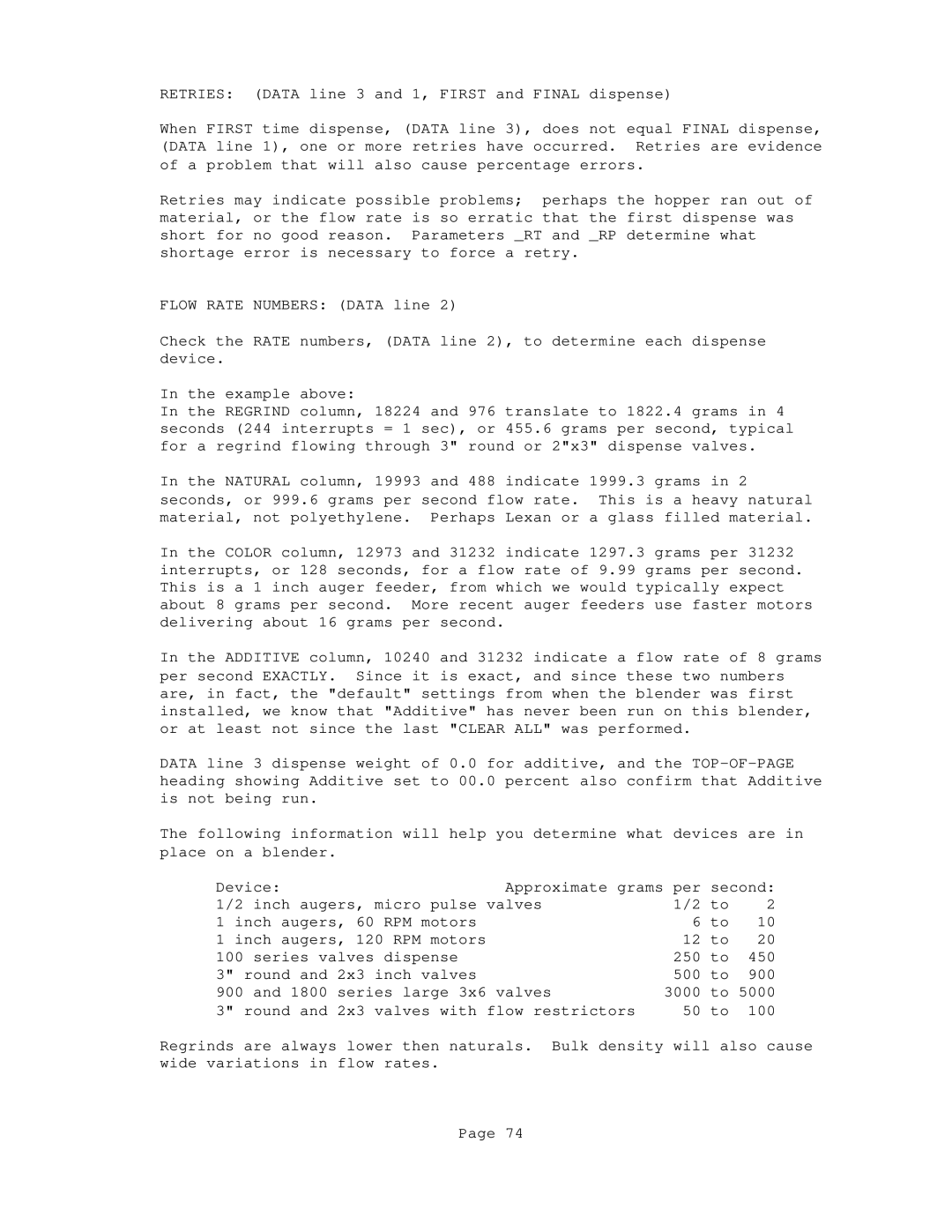

The following information will help you determine what devices are in place on a blender.

Device: |

| Approximate grams | per | second: | |

1/2 inch augers, micro pulse | valves | 1/2 | to | 2 | |

1 inch augers, 60 RPM motors |

| 6 | to | 10 | |

1 inch augers, 120 RPM motors |

| 12 | to | 20 | |

100 series valves dispense |

| 250 | to | 450 | |

3" round and | 2x3 inch valves |

| 500 | to | 900 |

900 and 1800 | series large 3x6 valves | 3000 | to 5000 | ||

3" round and | 2x3 valves with | flow restrictors | 50 | to | 100 |

Regrinds are always lower then naturals. Bulk density | will also cause | ||||

wide variations in | flow rates. |

|

|

|

|

Page 74