Rev 13 14-SEP-2011

BX HVAC, and CX Convenience Store Controllers

Page

FCC Compliance Notice

Page

Table of Contents

E2 Hardware Setup

Serial Configuration

E2 Ethernet Peer Communications

Quick Start

Software Overview

Logging Groups

Multiflex CUB Board

Holiday Schedules

OPERATOR’S Guide to Using the E2

LOW Battery Notification

Page

E2 Refrigeration Controller

Introduction

Mrlds

E2 Building Con- troller

E2 Convenience Store Controller

1 E2 I/O Network

Networking Overview

Able for the RS485 Network

Network

Interconnection With Other E2s

Documentation Over View

On-Line Help System Overview

Software Licensing

E2 Hardware

Hardware Overview

PIB LEDs Status

1 E2 Main Processor Board 3 E2 Keypad

LEDs

Gateway Board

I/O Network Boards and Peripherals

Main Board Status CPU LEDs

Keyboard Status

MultiFlex 16 Input Board

MultiFlex Boards

Gateway Model

Model Name Description

Model Description Name

MultiFlex Combination Input/ Output Boards

E2 RX/BX/CX I&O Manual Rev 13 14-SEP-2011

MultiFlex RTU BX and CX Only

MultiFlex CUB

MultiFlex Rooftop Control Board RCB BX and CX Only

MultiFlex PAK Board

Hand-held Terminal P/N

MultiFlex ESR Board

10- Hand-held Terminal

8RO and 8ROSMT Relay Boards

13- 4AO Analog Output Board P/N

6 4AO Analog Output Board

8ROe Dis

16AIe Dis

20- Case Controller CC-100P shown

ESR8 Dis

Facility Status Display FSD

6 TD3 Temperature Display

Page

Mounting the E2

Mounting

Standard Mount

Recessed Mount

Standard Mount Inside Rear of Enclosure

Retrofit Mounting

Single/Double Enclosures

Mounting I/O Boards

Blank Face

1 16AIe and 8ROe

Echelon Devices

Boards Without Enclosures Snap Track

5 TD3

3 ESR8 Dis

MultiFlex ESR

Internal Modem

Two-Channel and Four- Channel Repeaters

Mounting Repeaters Overview

Mounting the Two-Channel Repeater

Pressure Transducers

Inside Temperature Sensor

Sensors and Transduc Ers

Supply and Return Air Sen Sors

Outside Temperature Sen Sor

Insertion Temperature Probe

Humidity Sensors and Humidistats

Product Temperature Probes

Mounting Bullet and Pipe Mount Sensors

Indoor RH Sensor

Outdoor RH sensor P/N

Outdoor RH Sensors

Duct-mounted Insertion RH Probe

Light Level Sensor

Dewpoint Probe

Liquid Level Sensors

Refrigerant Leak Detectors

Page

Setting up the E2

E2 Hardware Setup

Enclosure

Main Processor Board

Powering the E2

Echelon Card Plug-In P/N 537-4860with mounting screw P/N

Add-On E2 Peripherals

Modem P/N Description

Plug-In Digital I/O Network Card P/N

5 E2 RS485 Port Card P/N 537-4890

Battery Testing and Replacement

Plug-In Four-Channel Inter- nal Repeater

LEDs

Battery Enable Switch

Low Battery Notification

Battery Test

Battery Replacement Qual- ified Technicians Only

Echelon Earth

Page

Serial Device and Soft Ware Setup

Serial Configura- tion

Overview

COM Ports

E2 COM# Associations Connector

I/O Network

RS485 Network and Hardware Setup

1 I/O Board Names and Termi Nology

Board

MultiFlex-Plus + Board

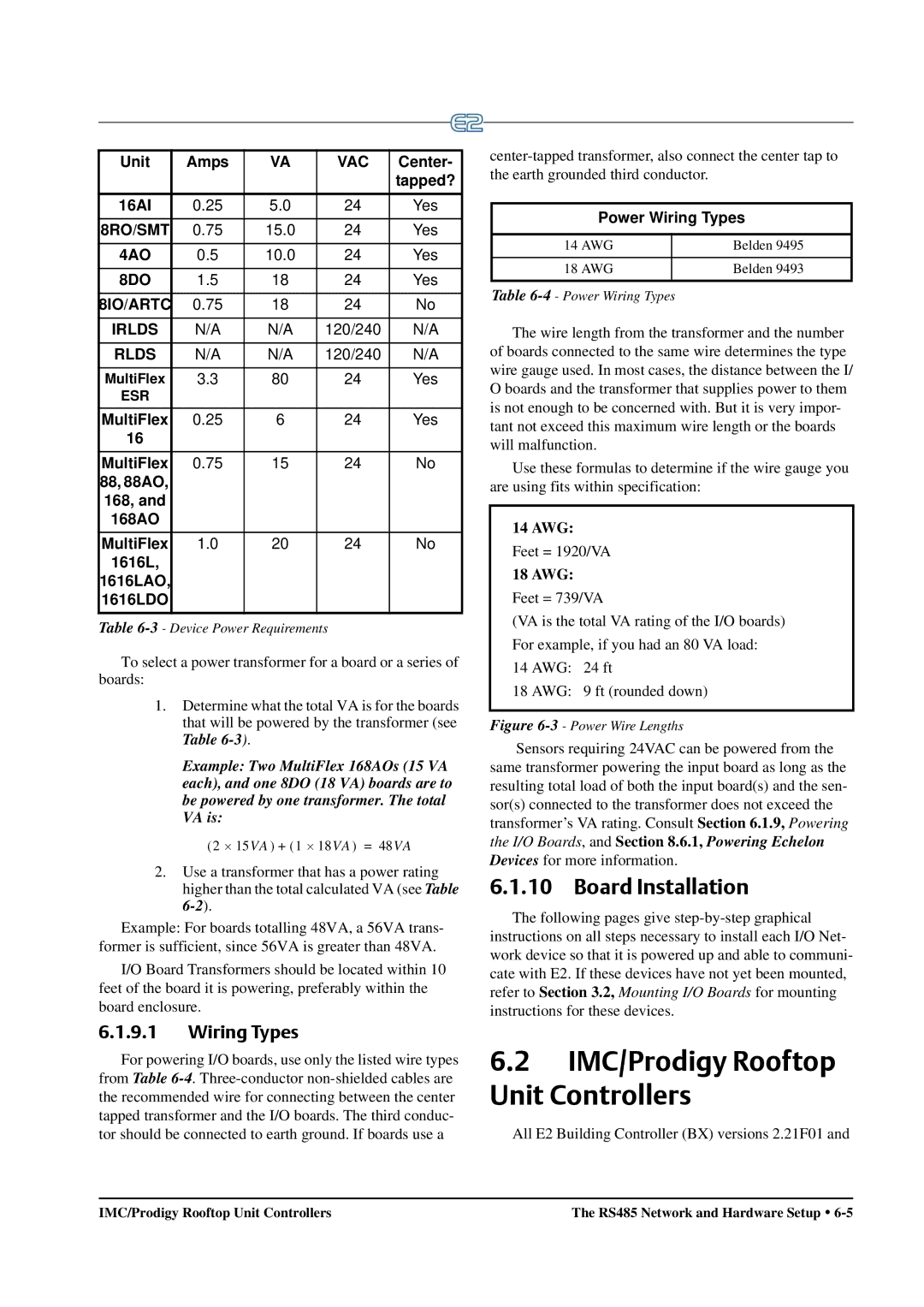

Wiring Types

I/O Network Structure Daisy Chains

Network Noise Minimiza Tion

Network ID Numbers Board Numbers

Setting the Baud Rate

Powering the I/O Boards

Setting the Terminating and Biasing Jumpers

IMC/Prodigy Rooftop Unit Controllers

Board Installation

Wiring Types

Control Techniques Drive

Copeland Discus with Core- Sense Diagnostics ISD

3 XR35CX, XR75CX, XEV22 Case Controllers

3.1 XR75CX-Case Display

Energy Meter

IPro DAC

Overview

Supported System Types

Diagnostic Alarm Descriptions E2 Advisory

Advisory and Alarms

Copeland Discus with Core- Sense Protection

Light Commercial Thermo Stat

Comfort Alert Descriptions Cause E2 Advisory

Comfort Alert Codes

Conditions for Return to Normal RTN on Diag- nostic Codes

High/Low Occ/Unocc Space Temperature Alarms

Supply Sensor Fail Alarm

Diagnostic Alarm Descriptions

Diagnostic Alarms

Refrigerant Leak Detection System Rlds

Copeland Scroll K5 Refrig- eration Compressor

11.1 XM670

XM Series of Case Control Lers

11.2 XM679

11.3 XM678

RS485 Network and Hardware Setup 6

14 E2 RX/BX/CX I&O Manual Rev 13 14-SEP-2011

NET

16 E2 RX/BX/CX I&O Manual Rev 13 14-SEP-2011

120/208/240 VAC

16AI Installation Guide

MultiFlex ESR Installation Guide

XEV22D Driver to E2 Installation Guide

XR35CX, XR75CX to E2 Installation Guide

Page

Equipment Specifications Type

Ethernet IP Configura Tions

E2 Ethernet Peer Communications

Hardware Specifica Tions

Closed Network Layout

Software Specifica Tions

Ethernet Network Layouts

Open Network Layout

Software Setup

5Peer Network Tab Set Group Name

Troubleshooting

Wiring Type

Echelon Network and Hardware Setup

Cable Type Retail Solutions Part Number

Loop Resistance

Maximum Number of Eche- lon Devices

Device Termination

Installing Echelon Devices

Wire Restrictions

Powering Echelon Devices

Maximum Total Segment Length

Open Echelon Device Connectivity

Configuring Echelon Devices

LEDs

Connected I/O Screen E2 firmware versions 2.81 and above

Troubleshooting

E2 RX/BX/CX I&O Manual Rev 13 14-SEP-2011

One pin when unterminating an

E2 RX/BX/CX I&O Manual Rev 13 14-SEP-2011

MultiFlex Boards

All Analog Temperature Sensors and Air Flow Sensors

16AI Boards

8IO and Artc Boards

Power Connection

Down

Sensor Input Type Wiring Dip Switch

Wall-mounted Down

207-1000 Refrigerant

MA output to input board

Sensor Input Type

20mA, Up for

Pulse

Association

Application

Pulse on

Sensor Type Description

Setting Up Digital Inputs

Set

8RO, 8ROe, 8IO, and MultiFlex Outputs

New 8ROs and 8RO-FCs

Old 8ROs

Setting Up Digital Outputs

Setting Up Analog Outputs

Connection

Temperature and Digital Sensors

Hand-Held Terminal Jack

Auxiliary Analog Input

335-3260 Generic Stepper and Emerson Flow Controls ESV Valve

335-3263 Pulse Valve

Pin

Page

Performing a Clean Out

Cleaning Out the Con- troller

Quick Start

Logging On

Unit Controllers Echelon

Setting Number of Network Devices

Boards on the I/O Network

Customizing the Home Screen

Setting Number of Applications

Header

Common Screen Ele- ments

Function Keys

Help Line

Main Menu

Screen Types

Status Screens

Actions Menu Item Description

Actions Menu

Key Function for

Menu Option Description

Setup Screens

System Configuration Menu

13- System Information Menu

System Information Menu

Setting the Time and Date

Time/Date Setup

Set Up Modem

17- TCP/IP Addressing

Set Up TCP/IP

10.11.2 I/O Network Baud Rate

Set Up Network Baud Rates

10.11.1 COM1 Serial RS232 Baud Rate

Level

Set Up User Access

Deleting a User

Changing Required User Access Levels

Creating a New User Account

Specify Number of Boards

Set Up I/O Network

Specifying Number Devices

Set Up Echelon Net Work

Checking Online Status

Commissioning a Device

Service Button Method

How Echelon Commissioning Works

Modbus Commissioning

TD3’s Service Button

CC-100’s Service Button

ESR8’s Service Button

Commissioning the EC-2

Manual ID Entry Method

License Management

33- TCP/IP Screen Locating the Mac Address

Web Services

37- Alarm Setup Menu

Set Up Alarming

Setting up an E2 to be an Alarm Annunciator

Specifying Alarm Reporting Types

Introduction Alarm Report Ing

Alarm Dial-Out

Priority Settings

Set Up Global Data

Example Setting Up an Outdoor Temperature Sen- sor

Set Up Applications

10.18.1 Add/Delete an Application

Using and Configuring a Setup Screen

Add an Application

Delete an Application

Entering Setpoints

Navigating the Setup Screen

Edit Menu

Help Line

Function Keys For Setup

Index Tabs

Using the Help Key to get Property Help

Page

Suction Groups

Software Overview

Introduction

Standard Suction Group Application

Hardware Overview

Learning Mode

Circuit Load Analysis

Control/Cycles Parameter

Input Sensor Type Wiring Instructions

Temperature Differential Strat Egy

Condenser Control

Air Cooled Condensers

Fast Recovery

Condenser Split Mode

Evaporative Condensers

Fan Control

Refrigeration Control

Standard Circuits

Defrost Control

Clean and Door Switches

Control Link CD Case Display

TD3 Temperature Display

Wiring

Typical Case in a Standard Circuit

Case Circuit Control Soft- ware Overview

Case Control Circuits

Overview

EEVs Liquid Pulse and Liquid Stepper

Valve Control

Off Cycle Timed

EEPRs Suction Stepper

Thermostatic Expansion Valves TXVs

Anti-Sweat Control

Temperature Termination

Demand Defrost

Wait State

Dual Temp Control

Clean/Wash Mode

Light Control

Dewpoint Input Sources

Walk-In Freezer Control

Fail-Safe Mode

Recoverable Sensor Failures

Logging Groups

Setting Up An Individual Case Controller

Data Compression

Possible Data Errors

Base Log Group

Clipping

Logging Setup Menu

Setting Up Logging

Log Reports

Logging Group Status Screen

System Log Report

Logging Group Report

Application Log Report

Air Handling Units

Temperature Control

Alternate Setpoints

Single-Speed Fans

Economizer Control

Economization Enable

Two-Speed Fans

Variable-Speed Fans

Analog Economizer Control

Digital Economizer Control

Dehumidification Control

Curtailment

Separate Setpoints

Inputs Sensor Type Wiring Instructions

AHU Zone Control

Intelligent Pre-Starts and Pre-Stops

Tion

Zone Control

Section

Applications That May Be Connected To Zones

How Zones Work

MultiFlex RTU Board

MultiFlex RCB Board

Economization Enable

Zone Temperature

Zone Humidity Input

Effect of Enabling Econ- omization

Effect of Enabling Dehu- midification

MultiFlex RTUs and RCBs

MultiFlex RTU/ARTC and AHU Zone Association

Losing Contact With Zone Applications

Stand-Alone MultiFlex RTUs

Lighting Schedules

MultiFlex CUB Board

MultiFlex PAK Board

Control Method Select

Functions of the Lighting Schedule Application

Standard Control

Light Level Interface Cell

Multi-Logic Combiner

Alternate Control

Schedule Interface Cell

Min ON/OFF Cell

Basic Schedule Cell

Proof Cell

Offset Solar Control

Output Light Dimming

Demand Control

Introduction to Demand Limit Control

Demand Monitoring

Shedding Levels

Load Shedding

Priority Levels

Definition

Other Notes About Priority Levels

Rotational Shed

Last Shed

How Demand Control Uses Load Shedding

Mode 1 KW Input Is Greater Than Setpoint

Mode 3 Integral Error Approaching Zero

Sensor Control

Power Monitoring Input

Analog Sensor Control

Cut In/Cut Out Setpoint Con Trol

Control Cells

Loop/Sequence Con Trol

Logical Combination

Loop/Sequence Control Cell Descriptions

Diagram

Output Cells

Select Cell

Output Cell Descriptions

How Schedules Work

Time Scheduling and Holidays

Events

Absolute and Relative Events

Holiday Schedules

Power Monitoring

Overlapping

Ranges

Hourly

Logging

Daily

Monthly

Heat/Cool Control

Anti-Sweat Setup

How Anti-Sweat Works

Unoccupied Hysteresis

Stops

Setpoint Reset

Lead/Lag

Analog and Digital Combiners

Configuration

Temperature Differential TD Strategy

TD Control

TD Control Fail-Safes

Pulse Accumulation

Alarms

Inputs

Outputs

Irrigation Control

Accumulator Reset Types

High Trip

Zones and Cycles

Zone Bypass Inputs

Cycle Scheduling

Zone Inhibit

Flow Sensor-Related Tests

Service Modes

Heat Cut In/Cut Out Set- points For Each Stage

Cool Cut In/Cut Out Set- points For Each Stage

Modular Chiller Con- trol MCC

Flexible Combiner

Compressor Control

Learning Mode

Control/Cycles Parame Ter

Bypass Valve Control

Boiler

Digital Scroll Compressor

Variable Frequency Drive Com Pressor

RMS Scale

RMS Asset

Log Information

Device Constraints

Unlogged Changes

Logged Changes

Page

BX Home Screen RX Home Screen

Operator’s Guide to Using the E2

E2 Home Screen

CX Home Screen

Logging On and Access Levels

Toggling Full Options

System Configuration Menu

Navigation

Menus

Actions Menu

System Information Menu

Screen Types

Setup Screens

Status Screens

Summary Screens

Index Tabs

E2 Keypad

Header Icons

Cursor

Keypad

Tab Key

Enter Key

Four Directional Arrow Keys

Log In/Out Key

Up/Page Down Keys

Ctrl Page Up/Ctrl Page Down Keys

Customizing the Home Screen

Manual Defrost and Clean Mode

Keys Function

Edit

Overrides

List menu and choose End Manual Mode

Checking Status Screens

Checking Boards Online

Accessing the Alarm Advi Sory Log

Alarms

Viewing the Controller Advi Sory Log

Date and Time

Area Ctrl Application Prop Erty

12.10.5 Ack/Reset State

Advisory Message

Acknowledging

Clearing

Resetting

Viewing Logs and Graphs

Facility Status Display FSD Alarms

Locating Logged Inputs Outputs

Home/Status Screens

Setting Up Input and Output Pointers

Setup Screens

Zooming In and Out

Log View

Low Battery Notifica Tion

Defrost Type

Appendix a Case Type Defaults

High Alarm, Low Alarm, and Delay

Hdbx

100 lb 200 lb 500 lb Xducer

Eclipse Transducers Voltage Pressure PSI

Page

Alarm Name Default Definition Priority

Appendix C Alarm Advisory Messages

E2 RX/BX/CX I&O Manual Rev 13 14-SEP-2011

Appendix C Alarm Advisory Messages C-3

Alarm Name Default Definition Priority

Appendix C Alarm Advisory Messages C-5

Alarm Name Default Definition Priority

Appendix C Alarm Advisory Messages C-7

Alarm Name Default Definition Priority

Appendix C Alarm Advisory Messages C-9

10 E2 RX/BX/CX I&O Manual Rev 13 14-SEP-2011

Appendix C Alarm Advisory Messages C-11

12 E2 RX/BX/CX I&O Manual Rev 13 14-SEP-2011

RAM

14 E2 RX/BX/CX I&O Manual Rev 13 14-SEP-2011

Throttling Range

Proportional P Mode

Appendix D PID Control

Why I Mode is Necessary

Integral Mode

Proportional Constant Kp

Throttling Range on page D-1

Saturation

Derivative Mode

I Mode Calculation

How Condenser Control Hvac PID Differs From Others

D Mode Calculation

Output at Setpoint

Output at Setpoint for Non-Condenser

Changing the Output at Setpoint

Other PID Features

Output at Minimum / Output at Max- imum

Output at Setpoint for Condenser/HVAC PID Control

Filtering

Minimum Accumulated Error

Page

Page

Medium Resolution

Reuccf

Page

Page

Refer to .1.9, Powering

Appendix F Troubleshooting

Echelon Network

Appendix F Troubleshooting F-3

Symptom Possible Problem Solution

Trip

Number of Fans field?

Symptom Possible Problem Solution

Appendix F Troubleshooting F-7

Figured as an analog input

Page

Page

Appendix G Revision Log

Page

Numerics

Index

Low 4-6,12-18

CS-100.See Case Controllers, CS-100

Demand Defrost. See Defrost, demand

Hot Gas Defrost. See Defrost, hot gas

Jumpers

PAK 2-7,11-30

Pmac

Hansen probe. See Sensors, liquid level

10 E2 RX/BX/CX I&O Manual Rev 13 14-SEP-2011

E2 4-2RS485 jumpers