HDP600 High Definition Card Printer/Encoder User Guide Rev

Part Number L000444

Restricted USE only

Table of Contents

General Troubleshooting

Card Lamination Module

Restricted USE ONLYFargo Electronics, Inc

Cleaning

Reviewing Spare Parts Lists

How to use the guide

Manual Description

Safety Messages review carefully

Reviewing the HDP600 Block Diagram

HDP600 Overview

Reviewing the HDP600 Sequence of Operations

Step Process

Reviewing HDP 600 Series Card Printer Sequence of Operations

Reviewing HDP 600 Series Card Printer Sequence of Operations

Reviewing the HDP600 Boot up Sequence

Reviewing the Lamination Module Sequence of Operations

Reviewing the Lamination Module Sequence of Operations

Reviewing the Lamination Module Boot up Sequence

Specifications

Table of Contents

Safety Messages review carefully

Introduction

Reviewing the HDP600 Printer Overview table

Reviewing the HDP600 Package

Reviewing the HDP600 front

Reviewing the HDP600 CR100 Card Printer

HDP600 Regulatory Compliances

HDP600 Agency Listings

Term

File Number E145118

Accepted Standard Card Sizes

Technical Specifications

HDP600 CR100 and HDP600-LC CR100 same reference

HDP600 and HDP600-LC

Technical Specifications

HDP600 CR100 and HDP600-LC CR100

Dimensions

Term Description

∙ 200 cards .030/.762mm

Memory Operating Temperature Options

HDP600/HDP600-LC

∙ 100 cards .030/.762mm

HDP600 CR100/HDP600-LC CR100

Print Ribbon Options Print Speed- Batch Mode

Description HDP600 and HDP600-LC

HDP600 and HDP600-LC see note below

HDP600 CR100 and HDP600-LC CR100 see note below

Technical Specifications

Function

Functional Specifications

Dye- Sublimation

Component

Component Description

Printer Components LCD and Softkey Control Pad

Softkey Buttons LCD Display

Fargo Electronics, Inc

Print Status Screen Cancel button

Printer Components LCD and Softkey Control Pad

Pause button LED Light

Component Description

Printer Components Print Ribbons

Type

Printer Components Blank Cards

Card Size Design Card Surface UltraCard stock

Printer Components Card Input and Output Hoppers

Card Input Hopper

Card Output Hopper Reject

Printer Components Card Output Hopper and Reject Hopper

Description HDP600/HDP-LC and HDP600 CR100/HDP600-LC CR100

Printer Unit Reviewing the Card Lamination Module

Controls Temperature Adjustment New Setting

Printer Components Transfer Roller

Reviewing the Overlaminates

Term Description Cross Reference

Reviewing the CR-90 or CR-100 Patch Size

Reviewing the Overlaminate Design

Installation Procedures

Restricted USE ONLYFargo Electronics, Inc

Safety Messages review carefully

Time Requirement

System Requirements

Inspection HDP600

Unpacking the Printer

Choosing a Good Location

About Moisture Condensation

Step Procedure

Printer Loading Procedures

Loading the Print Ribbon

Loading the Print Ribbon

Display B Loading the Print Ribbon supply spool

Display C Loading the Print Ribbon take-up spool

Loading the Print Ribbon

Loading clear HDP Film into the Transfer Station

Loading clear HDP Film into the Transfer Station

Display B Loading the HDP Film take-up spool

Display C Loading the HDP Film take-up spool

Inserting the Card Cleaning Cartridge

Inserting the Card Cleaning Cartridge

Display B Inserting the Card Cleaning Cartridge

Inserting the Card Cleaning Cartridge

Loading the Overlaminate

Loading the Overlaminate

Loading the Overlaminate

Loading the Overlaminate

Loading the Overlaminate

Connecting power to the HDP600 Printer

Connecting power to the HDP600 Printer

Display B Connecting the AC power cable to the power supply

Connecting power to the HDP600 Printer

Connecting power to the HDP600 Printer

This applies to the HDP600-LC Printer only

Connecting power to the HDP600 Printer

Connecting power to the HDP600 Printer

Display H Displays the Printer power switch ON/OFF

Loading the Blank Cards

Loading the Blank Cards

Display B Loading the Blank Cards into the empty Hopper

Display C Inserting the Card Weight Push to the back

Printer Driver Installation Procedures

Installing the HDP600 Printer Driver

Installing the HDP600 Printer Driver

Display a Select HDP600 Card Printer/Encoder below

Installing the HDP600 Printer Driver

Display B Please wait during installation

Click on the Next button to continue with the installation

Installing the HDP600 Printer Driver

Installing the HDP600 Printer Driver

Installing the Printer Driver Windows 2000 Only

Click on the Install button to begin the installation

Installing the Printer Driver Windows XP Only

Wait during the installation

Installing the HDP600 Printer Driver

Installing the HDP600 Printer Driver

Installing the HDP600 Printer Driver

Installing the HDP600 Printer Driver

Installing the HDP600 Printer Driver

Installing the Printer Driver Windows XP Only

Installing the Printer Driver Windows XP Only

Installing the Printer Driver Windows XP Only

Installing the Printer Driver Windows XP Only

Installing the Printer Driver on Windows XP only

Step Procedure You have completed this procedure

Printing a Test Print Image

Printing a Test Print Image

Display a HDP600 Printer Driver Card Tab

Printing a Test Print Image

Card Lamination Module Installation

Introduction

Inspecting the Card Lamination Module

Unpacking the Card Lamination Module

Choosing a proper Location

Preventing Moisture Condensation

Installing the HDP600 Series Card Lamination Module

Estimated Repair Time Ten 10 minutes Procedure

Steps

Display a Output Bin and Output Bin Stop Latch

See the previous

Installing the HDP600 Series Card Lamination Module

Display B Lam-Ready Output Bin

Step Description

Com

Installing the HDP600 Series Card Lamination Module

Installing the HDP600 Series Card Lamination Module

You have completed this procedure

Installing the Printer Diagnostic Utility

Installing the Fargo Diagnostics Utility

Installing the Fargo Diagnostics Utility

Installing the Fargo Diagnostics Utility

Installing the Fargo Diagnostics Utility

Wait while the files are being copied, as shown below

Installing the Fargo Diagnostics Utility

Display a HDP600 Printer Driver Card Tab

Printing a Test Print Image

General Troubleshooting

Cause Solution

LCD Messages

Reviewing LCD Messages

Message

Reviewing LCD Messages

Cause

Message Cause

Message Cause Solution

See the HDP600 Printhead Replacement Procedure procedure

Reviewing LCD Messages

Reviewing LCD Messages

Lam Error Lamination Module requires

Wrong Lam Type Failed to verify the encoded mag data

LAM

General Troubleshooting Guide

Problem

Possible Solution

Ribbon Wrinkle Film Wrinkle

General Troubleshooting Guide

Problem Possible Solution

General Troubleshooting Guide

General Troubleshooting Guide

Magnetic and E-card Troubleshooting Guide

Magnetic and E-card Troubleshooting Guide

Printing a Test Image

Reviewing the Gray/Align YMC/K Self-Test

Reviewing the Color/Resin Ymck Self-Test

Reviewing the Color Bars YMC Self-Test

Reviewing the Card Count Self-Test

Reviewing the Magnetic Test option

Reviewing the Lamination Color/Resin YMCK+L Self-Test

Ethernet Option Section

Reviewing Frequently-asked Questions

Here are the system requirements for Ethernet

Technical Specification Ethernet Option

Requirement

Functional Specification Ethernet Option

Fargo Ethernet option includes these features

Feature

Upgrades Troubleshooting IP Tracer

Reviewing the Print Server

Reviewing the Web Page Server

Reviewing the Network Management Interface

Reviewing the Telnet Server

Snmp interface is described below

Initiating a Telnet Session

Interface

Reviewing the Telnet Command Table

Telnet Command

Command Purpose

Command Format

Reviewing the Telnet Command Table

List all Diff

Lpq Printer

Set syslog from defaultcurrent

Set sysinfo contact location label From

Set User Add

Add a new User definition Up to four 4 Users may be defined

Store Net Addr Mask Gateway Dns Domain Opts

Command Purpose Command Format

Save Load Lpstat Cancel Quit

Reviewing Web page security

Logging

Accessing the Home pages

Reviewing the HDP600 Home

Category Field

Reviewing the Home Page Categories and Fields table

Purpose

Accessing the Network Settings

Configuring the Network Settings

Select the Network link from any web page of the Printer

Reviewing the Interface

Reviewing the Current Settings

Switching to the automatic IP address mode

Changing to the static IP address mode

Changing to the static IP address mode

See the Reviewing Web page security procedure

Entering the TCP Window Size

Using the Clear Changes button

Using the TCP/IP

Using the TCP/IP Status Web

See the Using the TCP/IP page procedure

Status Device Print Jobs

Using the Printer

Status

Reviewing the Printer

See the previous page for descriptions of the fields

Using the System Log

Changing the Log Name

Select the System Log link

Changing the Log Name

Selecting the Log Type

Selecting the Log Destination

Step Procedure No event logging

Specify one destination for the log

Setting up Email Event logging

Step Procedure Specify email logging

Specifying UDP Event logging

Specifying UDP Event logging

Specifying TCP Event logging

Specifying TCP Event logging

Using the System Information

Using the Administration pages

∙ Location textbox ∙ Contact textbox

Using the System Information

Changing the Root Password

Changing the Root Password

Upgrading the Print Server

Upgrading the DTC400 and HDP600 Print Server

Using the Reboot pages

Rebooting the Ethernet Server

Rebooting the Ethernet Server

Resetting to Default Settings

Using the Help

Help page displays the Help information

Reviewing LED and Dipswitch Tables

LEDs and dipswitches can be found on the back of Printers

Reviewing the LED Table

LED HDP600 Flash Rate position Indicates

Reviewing the Dip Switches

Dipswitch

Forces Default IP

Comments

Restoring the Factory Settings for Ethernet

Restoring the Default Settings

Accessing the IP address of your Printer

Accessing the HDP600 IP address

Start Programs Fargo Fargo Diagnostic Utility

Restricted USE only

Troubleshooting procedures

Follow the Printing a test page procedure

Verifying the Printer Connection

Verifying the Printer IP address

Step Procedure

Printing a test

Question

Answer

See Accessing the IP address of your Printer

Reviewing Frequently-asked Questions Answer

See Upgrading the Print Server

Reviewing Frequently-asked Questions Answer

Reviewing Frequently-asked Questions

Select Next, Next, Finish and Close

Reviewing Frequently-asked Questions

Glossary of Terms

Term Purpose

Glossary of Terms

Card Lamination Module

Reviewing the Card Lamination Module

Safety Messages review carefully

Opening the Card Lamination Module

Opening the Card Lamination Module

Adjusting the Card Lamination Module

Adjusting the Card Flattener

Printer Adjustments

Restricted USE ONLYFargo Electronics, Inc

Safety Messages review carefully

Adjusting the Card Size

Adjusting the Card Thickness Adjustment Lever

Printing on Alternate Card stocks

Selecting the Right Cards and optimize the HDP Print Process

Selecting the Appropriate HDP Printer Driver settings

Card/Ribbon Type

Transfer Temp

190º 195º

Conducting the Tape adhesion Test

Conducting the Tape adhesion Test

Conducting the Tape adhesion Test

Installing Printer Driver Updates

Printer Driver Options

Setting Up the Printer Driver

Setting up Windows 2000/Windows XP

Using the Card tab HDP600/HDP600-LC

Use this option to control specific Printer functions

Using the Card tab HDP600 CR100/HDP600-LC CR100

Selecting the Card Size HDP600 and HDP600-LC

See three previous procedures

Selecting the Card Size HDP600 and HDP600-LC

Selecting the Custom Card Size

Selecting the Card Type all HDP600 Printers

Selecting the Card Type

Selecting the Card Hopper HDP600 and HDP600-LC only

Selects the appropriate Card Hopper

Restricted USE only

Specifying the number of Copies

Setting the Orientation

Specifies the number of copies to be printed

This will launch the Diagnostic tool if installed

Selecting the Diagnostics button

Selecting the Test Print button

Selecting the About button

Using the Device Options tab HDP600/HDP600-LC

Using the Device Options tab HDP600 CR100/ HDP600-LC CR100

Adjusting the Ribbon Type

Use the Ribbon Type dropdown menu to match Ribbon type

Adjusting the Film Type

Adjusting for the Color Matching

Adjusting for the Color Tone Natural or Enhanced

Select the appropriate

Adjusting for the Resin Dither

Using the Print Both Sides option

Using the Split 1 Set of Ribbon Panels option

Using the Print Back Side First option

Using the Print Back Side Only option

Use this option to print only onto the backside of cards

Step Procedure

Using the Print in Single Card Mode option

Using the Disable Printing option

Using the Image Color tab HDP600

Using the Image Color tab

Using the Image Color tab

Using the Image Color tab

Using the Image Transfer tab

Adjusting the Image Position controls

Step Procedure

Adjusting the Transfer Dwell Time and Temperature

Using the K Panel Resin tab

Selecting the Full Card with the K Panel Resin tab

Selecting the Defined Areas with the K Panel Resin tab

Selecting the Undefined Areas with the K Panel Resin tab

Defining the Area to activate the Card Grid

Measuring the Total Card area

Measuring the Area to be positioned on the Card

Selecting the Print YMC under the K and Print K Only options

Using the Magnetic Encoding tab

Using the Encoding Mode option

Using the Encoding Mode option

Encoding the Mode/Coercivity/Magnetic Track Selection

Encoding the Mode/Coercivity/Magnetic Track Selection

Reviewing the Magnetic Track Options

Reviewing the Enable MLE Support checkbox

Reviewing the Verification options

Reviewing the Shift Data Left

Reviewing the ISO Track Locations

Sending the Track Information

Reviewing the Sample String

Track Start End

Field Valid Characters

Maximum Number Characters

Reviewing the Ascii Code and Character Table

Using the Lamination tab only with Card Lamination Module

Selecting the Lamination Position

Selecting the Lamination Side

Selecting the Lamination Type

Adjusting the Transfer Dwell Time and Transfer Temperature

Selecting the Sensors button and Defaults button

Selecting the Sensors button and Defaults button

Cleaning

Using the Required Supplies

Safety Messages review carefully

Cleaning inside the Printer

Cleaning outside the Printer

Cleaning the Printhead

Replacing the Card Cleaning Tape

Steps Procedure

See the previous procedure in this section

Cleaning the Magnetic Encoder

Cleaning the Magnetic Encoder

Cleaning the Platen and Transfer Rollers

Cleaning the Transfer Rollers using the Cleaning Card

Packing the Card Printer

Board Level Diagnostics

Resolving the EE Memory Error

Board Errors

Resolving the EE Checksum Error

Resolving the Dram Memory Error

Resolving the RAM Memory Error

Resolving the Fpga Error

Sensor Testing

Symptom An unexpected hardware error has occurred

Sensor or Switch Location Low Range VDC High Range VDC

Reviewing the Sensor Locations and Voltages

Reviewing the Sensor Locations and Voltages

Motor Cable

Reviewing the Motor Locations and Cables

J31 J34 J33 J32 J28 J30 J29

LCD On-Line Menu Navigation

Entering the LCD Menu and selecting an Option

Selecting from the HDP600 Menu Option Structure Tree

Reviewing the Printer Setup

Reviewing the Printer Setup

Select Transfer TOF

Aligning the Print Offset

Aligning the Print Offset

Setting the Transfer TOF

Setting the Transfer TOF

Setting the Transfer EOF

Setting the Transfer EOF

Using the Gap Distance Table

Using the Gap Distance Table

Using the Gap Distance Table

Adjusting the Transfer Tension

Select MENU, Setup Printer and Transfer Tension

Adjusting the Film Drive

Adjusting the Ribbon Tension

Adjusting the Transfer Temperature

Adjusting the Ribbon Drive

Adjust the Transfer Temperature value

Adjusting the Transfer Speed

Setting the Printhead Resistance

Adjusting the Image Darkness

Changing the Encoder Settings

Setting the Magnetic TOF

Setting the Magnetic TOF

293 / 7.44mm Magnetic Track Data

Adjusting the Flipper Offset

∙ Mag/Prox ∙ Level ∙ Smart ∙ Inverted ∙ Home

Adjusting the Lamination Flipper Offset

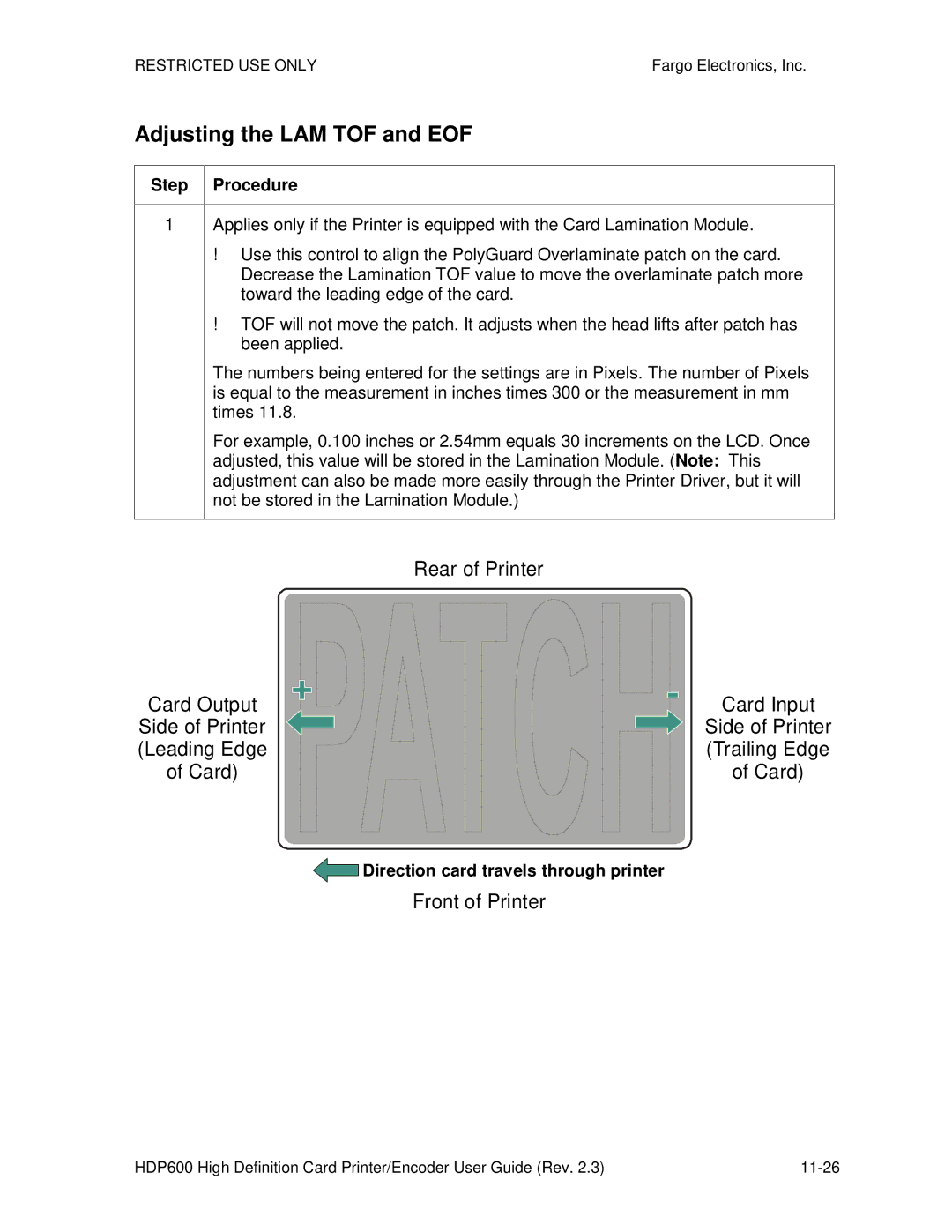

Adjusting the LAM TOF and EOF

Front of Printer

Adjusting the Lamination Sensor Calibration

Adjusting the Lamination Temperature Setting

Using the Show Card Count option

System Upgrade Firmware Upgrade

This option is used to upgrade the Printer Firmware

Upgrade by selecting System Upgrade

LCD will prompt Are you sure you want to continue?

Firmware Updates

Firmware Updater Application Program

Firmware Updater Application Program

Downloading Firmware Updates

Updating the Printers Firmware

Updating the Main Firmware

Updating the Main Firmware

Updating the Main Firmware

Updating the LCD Firmware

Updating the LCD Firmware

Fargo Technical Support

Contacting Fargo Technical Support

Finding out when a Fargo Card Printer was manufactured

Reading the Serial Numbers on a Fargo Printer

Reviewing Example No Serial Number

Reviewing Example No Serial Number A1280224

Reviewing Spare Parts Lists

Glossary of Terms

Definition

Barcodes

Cache

Glossary of Terms

Term Definition

Dwell Time

Eeprom

Encoder wheel

Glossary of Terms

Hard Drive Hardware HDP High Definition Printing

JIS II Japanese Industrial Standard

Glossary of Terms

Glossary of Terms

Glossary of Terms

Pinch Roller Pixel Platen

Printhead

Glossary of Terms

Saturation Self-test Sensor

Temp file Test Print Thermistor

Glossary of Terms

YMC Ymck Ymckh Ymckk Ymcko

Index

Embedded contaminants

Gray/Align YMC

Print Test Image

Sending Update to Printer dialog, 12-6,12-7 Sensor

Upgrade Failed or Upgrade Firmware Now on

Appendix a

Display a CR-100 Menu Tree

Display B CR-80 Menu Tree