Gemini User’s Manual

Paper

“Needle” pin

Sprlng

-

| Platen |

| Pln gulde |

r | Iron core I ‘IL |

$- |

I

Ribbon guide

Clapper

\’ Bobbin

Printer solenoid

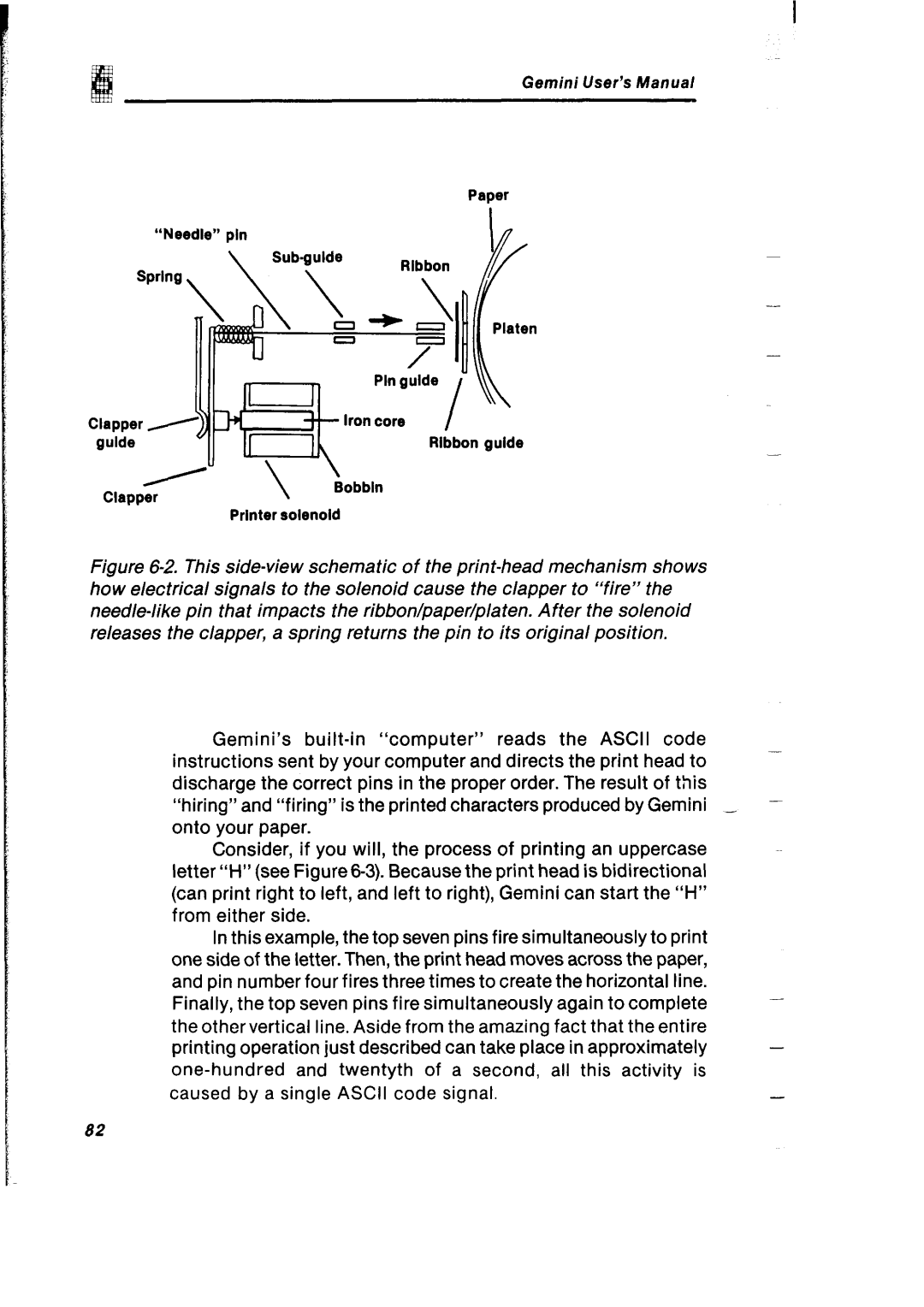

Figure 6-2. This side-view schematic of the print-head mechanism shows how electrical signals to the solenoid cause the clapper to “fire” the needle-like pin that impacts the ribbon/paper/p/a ten. After the solenoid releases the clapper, a spring returns the pin to its original position.

Gemini’s

Consider, if you will, the process of printing an uppercase letter “H”(see

In this example, the top seven pins fire simultaneously to print one side of the letter. Then, the print head moves across the paper, and pin number four fires three times to create the horizontal line. Finally, the top seven pins fire simultaneously again to complete the othervertical line. Aside from the amazing fact that the entire printing operation just described can take place in approximately

82