OperatingInstructions

Page

Foreword

General notes on service

Continual development

For technical exigencies requiring particular attention

Foreword

September

Max Holder GmbH Max-Holder-Straße Metzingen

Foreword

Table of contents

Page

Unintended use

Information on the tractor

Intended use

Site of operation

Residual hazards and risks

Information on the tractor

Disposal instructions

Over 32 km/h

Operating instructions

Driver’s licence

Driver’s licence classes

Operating instructions

Operating instructions

Previous drivers licence class

Working clothes

Safety

General notes on safety

Safety notes for retrofits

Gear oil, engine oil, diesel fuel

Safety instructions for handling fuel, fluids and lubricants

Hydraulic oil, brake fluid

Battery acid

Emissions Exhaust Gases

Heat

Battery

Tractor dimensions

Technical data

Dimensional drawing

Table of dimensions for S

Technical data

Distance between centreline of tires

Technical data

Weights

Curb weight Max. loading Type

990

Engine specifications

Theoretical ground speeds

Fuel system

Technical data /filling quantities

Front lift

Assembly Additional Description Information Steering

Brakes

Tow coupling

Dump body

Assembly Additional information Description Rear lift

Traction hydraulics

General tractor

Electrical system

Exhaust gas identification

Noise level

Views of vehicle

Description

Front left view

Tractor

Description

Rear right view

Operating controls

Driver’s station

Controls on right front console

Controls on right rear console

Hand throttle

Controls on rear console

Joystick

Description

Pedals

Steering column adjustment

Indicator lights

Controls at front bottom of cabin

Controls at front top of cabin

Door controls Door opener

Controls at rear of cabin

Identification plates

Location of plates and labels

Mounting instructions for licence plate

Overview of options and variants selection

Assembly Additional information Dimension/order No./type

Operating Instructions

A11VO40EP

Accessories

Page

Daily checks and activities prior to taking into service

Taking into service

Checking/cleaning the radiator and protection screens

Checking the engine oil level

Taking into service

Turning on the battery isolating switch

Battery can be switched off fully with the removable key

Checking the trailer coupling optional if necessary

Taking into service

Checking the tire inflation pressure

Checking the hydraulic oil level

Filling fuel

Checking the brake fluid level

Adjusting the steering wheel

Adjusting the backrest tilt

Adjusting the driver’s seat with pneumatic suspen- sion

Do not adjust the seat while driving. Risk of accident

Adjusting the lumbar support

Adjusting the horizontal suspension

Adjusting the driver’s weight

Horizontal seat adjustment

Checking the lights and rear view mirror

Topping up wiper water

Before starting, make sure no-one is

Do not start or run the engine in enclosed

Spaces. Danger of poisoning through exhaust

Gases

Starting the engine

BildC992H074

Checking the brakes and steering for proper function

Page

Operation

Driving safety rules

Before starting to drive

Driving with hydrostatic drive

Tractor must be stationary for switching

Operation

Driving

Operation

Stop

Table of driving programs Position Marking Function Use

Selecting road travel transport speed

Setting the operating speed of programs 3

BildC992H024

Adjusting the fine adjustment knob

Driving with SDS Special Drive System

Changing the direction of travel

Operating the inching pedal

Table of ground speed ranges with Dual Drive

Driving with hydrostatic Dual drive

Drive the tractor warm for approx -12 min. at range

Set the program switch to range

Switching the differential lock off

Switching the differential lock on

Two-stage steering

Steering

Brakes

Operating the service brake

Applying the parking brake

Releasing the parking brake

Driving on slopes

Hydraulic oil for stationary operation

Special operating instructions

Stationary operation

Park the tractor on level ground in both direc- tions

340 Nm

Adjusting the track width

Identical spacers must be installed on all four wheels

Special operating instructions

Special operating instructions

Operation in winter

Operating the attachments

Safety instructions for handling attach- ments

Possible attachments

Additional information for attachments

Operating the attachments

Rear attachment or front/rear combinations

Operating the attachments

Front attachment

Operating Instructions

Installation of attachments

Adjusting the hitch insert length

Adjusting the catch hooks

Hole Position Used for

Both threads must be screwed in equally far

Adjusting the upper link slide and upper link

Coupling the hydraulic hoses

Removing attachments

Installing the articulated shafts

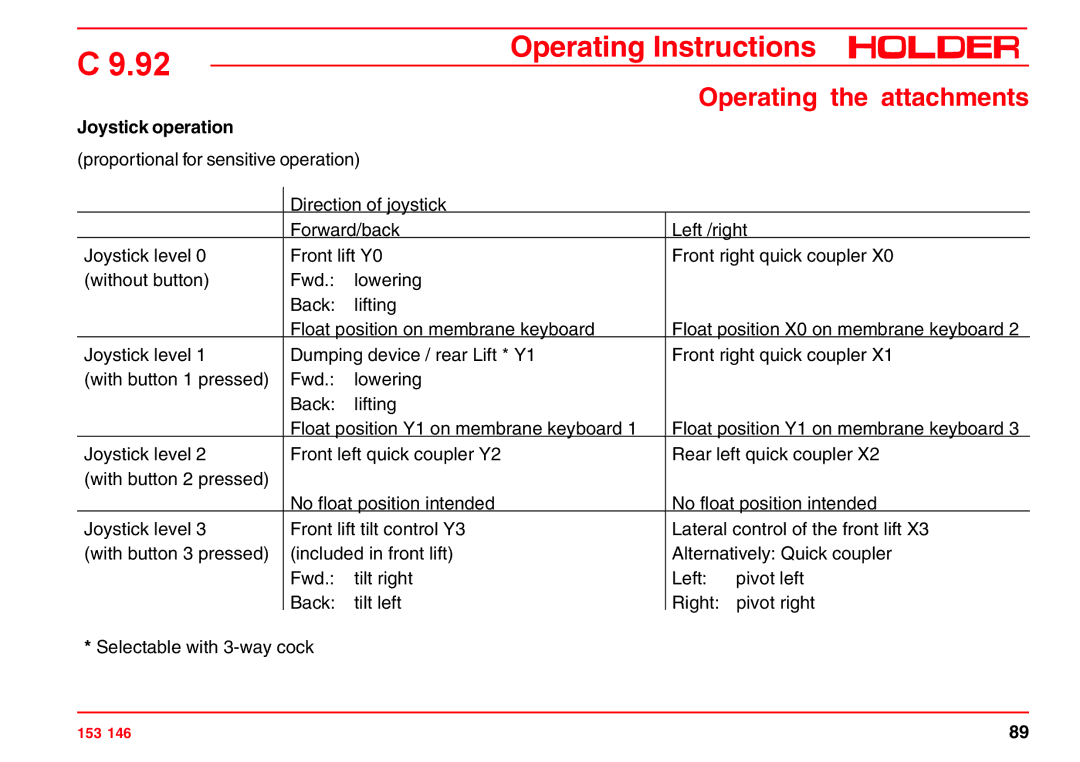

Operating the joystick

Joystick operation

Front lift tilt control

Operating the front lift

Lateral control of the front lift

Operating the front lift with the membrane keyboard

Adjusting the tilt with membrane keyboard

Switching the front lift to double-acting

Lateral control with the membrane keyboard

Transport safety

External operation of the front lift

Flow rate limiting for joystick

Setting key for float position button

Operating the rear lift

External operation of the rear lift

Operating the hydraulic couplings

Operating the blue hydraulic couplings

Operating the green hydraulic couplings

Operating the yellow and white hydraulic couplings

Turning on the front PTO

PTO switch 1 must be switched off

Before turning the PTO on, make sure that

Never turn the PTO on with the engine off

Turning on the rear PTO

Operating the hydraulic accumulator* front lift

Adjusting control sensitivity hysteresis

Gas pressure in the diaphragm accu- mulator is 30 bar

Applications with hydraulic accumulator

Switching the hydraulic accumulator off

105

Turn on the safety switch 6 only at low en- gine speed

S990 Variable pump flow

Switching off the attachment variable pump

Turn on the safety switch only at low engine speed

Operating the hydraulic system* fixed setting 80 L

Increase the speed of the engine slowly

Switching off the hydraulic system

Operating the hydraulic dumping device

Press button 4 only at low engine speed

Operating priority flow valve

Turning off the priority flow valve

113

114

Connecting line for priority flow valves 1

Page

Removing the roof hatch

Other operations

Operating the driver’s cabin

Operating the roof hatch Opening the roof hatch

Operating the windshield wiper/washer

Other operations

Front windshield wiper/washer

Other operations

To flash the headlights, pull the turn signal lever up

120

Turning on the top headlights

Activating the left / right turn signal

Operating the horn

Turning on the top strobe warning light

Operating the 4-way hazard flashers

Working light must not be used in public traffic

Turning on the working lights

Dome light Turning on the dome light

Radio* and loudspeaker Operating the radio

Power socket Connecting equipment to the power socket

Heating and ventilating Turning on the heating

Heater

Ventilation fan has 2 speeds

Turning on the ventilation

Recirculating air operation

Other operations

Air conditioning

Cleaning the condenser

Air conditioning

Operating the air conditioning

Fuses for the tractor

Fuses

130

Leaving the tractor unattended

Parking the tractor

Stopping the tractor

Parking

Parking the tractor

Leaving the tractor unattended

Trailers, towing

Operating the trailer coupling, attaching trailers

Trailers, towing

Driving with a trailer

Page

Do not step or stand under a suspended load. Danger to life

Transport, hoisting, towing

Transport instructions

Hoisting instructions

Towing instructions

Transport, hoisting, towing

Transport, hoisting, towing

Page

Adjusting the speedometer

Indicators, adjustments

Indication of special operating conditions

Page

Malfunction Cause

Malfunctions, causes, remedy

Engine and exhaust gas turbocharger mal- functions

Traction electronics and traction hydraulics malfunctions

Malfunction Cause Remedy

Malfunctions, causes, remedy

Malfunctions, causes, remedy

146

Hydraulic and steering system malfunctions

148

Working hydraulics malfunctions

150

151

152

How to value the tractor?

General remarks on maintenance

Qualification of service personnel

Service

Safety notes for maintenance

General remarks on maintenance

Handling fuel, fluids and lubricants

General remarks on maintenance

Doing work on the electrical equipment

Disconnect the battery ground lead

Jacking up

Jack lift points

Securing the dumping subframe dump body

Raise the cabin carefully

Tilting the cabin

Page

Maintenance during the initial period of operation

Maintenance schedule

See

Regular maintenance

Maintenance schedule

Interval Service and inspection Maintenance as required

Periodic maintenance

Maintenance every 1000 service hours

Maintenance every 500 service hours

Change the front and rear gearbox oil

Maintenance every 5 years

Interval Service and inspection Maintenance every 2 years

Checking air tubes and air hoses for leaks

Maintenance during the initial period of operation

Maintenance after the first 50 service hours

Checking the engine for leaks

Checking the coolant level, topping up if necessary

Maintenance after the first 50 service hours

168

Checking engine V-belt tension and condi- tion

Maintenance after the first 50 service hours

Adjust V-belt tension only when the engine is shut off

Checking the heating hoses for damage and tightness

Checking the hydraulic oil level

Checking the hydraulic lines and hoses for leaks and damage

170

Replacing the working hydraulics pressure filter

172

Replacing the traction hydraulics pressure filter

Changing the front and rear gearbox oil

Change the gear oil only when at operating temperature

Changing the front gearbox oil including axle

174

Filling oil

175

176

Checking the parking brake for proper op- eration

Check the service brake

Do not operate the tractor with a defective braking system

Tightening nuts and bolts according to the torque table

Tightening the wheel nuts

178

Maintenance after the first 500 service hours

Oil

Maintenance after the first 500 service hours

Cleaning

Maintenance after the first 500 service hours

Replacement

Hydraulic system is vented automatically

Approx L

Checking the engine valve clearances

Maintenance as required

Switch settings Combination Tire size Type

Maintenance as required

Checking the air cleaner system, cleaning if Necessary

Maintenance as required

186

Replacing the hydraulic return filter for hydraulic system

Cleaning with compressed air

Checking the radiator, cleaning if necessary

Cleaning with cold cleaner or water jet

Cleaning the condenser

190

Greasing the tractor except universal joints

Checking the frost protection of the windshield washer water

Checking the engine oil level

Maintenance every 250 service hours

Checking the air tubes and air hoses for leaks

Checking the coolant, adding if necessary

Maintenance every 250 service hours

Maintenance every 250 service hours

Checking the front and rear gearbox for leaks

Checking the service brake

Checking the fuel lines for condition and tightness

Checking the cable connections

Checking the air conditioner for proper operation

Checking the heating system for proper operation

Visual inspection of air conditioner for leaks

Checking the air conditioner hoses and wiring for damage

Checking the seat of the compressor

Checking the condensate water drain

Checking the preheating system

Lubricate the machine except universal joints

Tightening nuts and bolts according to the torque table

Checking the windscreen wiper, renewing if necessary

Checking the tire inflation pressure Tighten the wheel nuts

10.5 L

Maintenance every 500 service hours

Changing the engine oil at least once a year

Oil Unscrew the oil drain plug

Changing the engine oil filter

Maintenance every 500 service hours

Replacing the fuel filter element

Maintenance every 1000 service hours

Checking the engine valve clearances

Checking the glow plugs

Lubricating the universal joints at least once a year

Maintenance every 1000 service hours

Changing the hydraulic oil at least every 2 years

Maintenance every 1500 service hours

Page

Replacing the injection nozzles

Maintenance every 3000 service hours

This work may only be carried out by your service centre

Changing the toothed belt

Page

Changing the fresh air filter

Annual maintenance

Changing the air filter element

Changing the brake fluid

Checking the battery, coating the terminals with grease

Annual maintenance

Lubricating the universal joints

Page

Changing the hydraulic oil or at 1500 hours

Maintenance every 2 years

Changing the coolant

Replacing the V-belt

Replacing the air conditioner V-belt

Maintenance every 2 years

Secure the annular fan screws with Loctite

Changing the toothed belt or at 3000 hours

Maintenance every 5 years

Page

Engine preservation

Taking the tractor out of operation

Removing the engine preservation

Taking the tractor out of operation

Coolant, fuel and lubricant specifications

Page

Filling quantities 990

Maintenance data

Engine Torque Transmission, axles, wheels

Maintenance data

List of replacement parts

Maintenance data

Designation Order number

Bulbs 12 Use Power Rating

Technical data of the engine

226

Alphabetical index

Adjusting the driver’s seat with pneumatic suspension

210

Alphabetical index

Index

Alphabetical

230

231

232

233

234

235

236