| About This Document |

About This Document | 1 |

|

|

This document provides layout information and guidelines for designing platform or

This document is intended to be used as a guideline only. Intel recommends that you employ best- known design practices with

1.1Terminology and Definitions

Table 1. | Terminology and Definition (Sheet 1 of 2) |

| |||||||

|

|

|

|

|

|

|

|

|

|

| Term |

|

|

|

|

|

| Definition | |

|

|

|

|

|

|

|

|

|

|

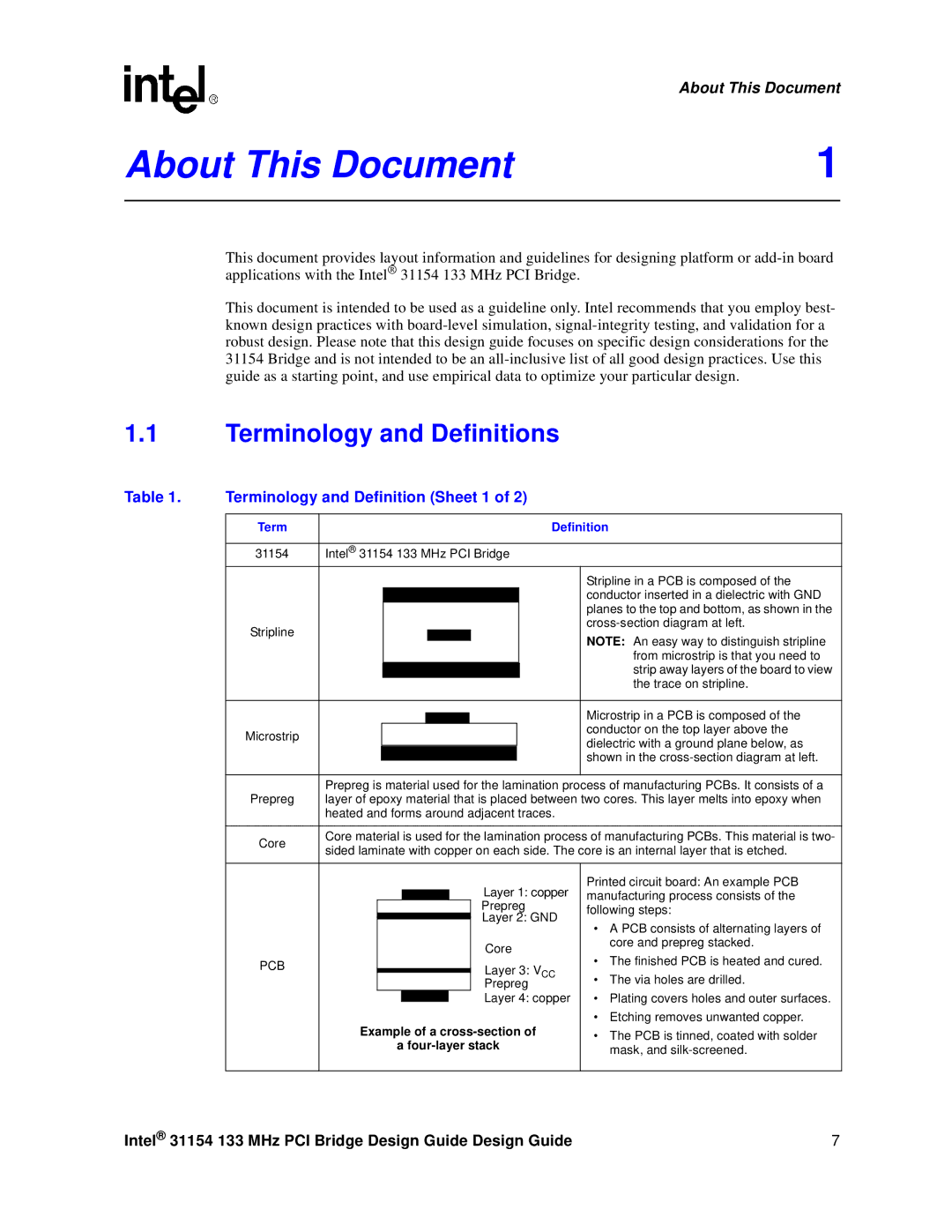

| 31154 | Intel® 31154 133 MHz PCI Bridge |

| ||||||

|

|

|

|

|

|

|

|

| Stripline in a PCB is composed of the |

|

|

|

|

|

|

|

|

| conductor inserted in a dielectric with GND |

|

|

|

|

|

|

|

|

| planes to the top and bottom, as shown in the |

| Stripline |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| NOTE: An easy way to distinguish stripline | |

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| from microstrip is that you need to |

|

|

|

|

|

|

|

|

| strip away layers of the board to view |

|

|

|

|

|

|

|

|

| the trace on stripline. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Microstrip in a PCB is composed of the |

|

|

|

|

|

|

|

|

| |

| Microstrip |

|

|

|

|

|

|

| conductor on the top layer above the |

|

|

|

|

|

|

|

| dielectric with a ground plane below, as | |

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| shown in the |

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

| Prepreg is material used for the lamination process of manufacturing PCBs. It consists of a | |||||||

| Prepreg | layer of epoxy material that is placed between two cores. This layer melts into epoxy when | |||||||

|

| heated and forms around adjacent traces. |

| ||||||

|

|

|

|

|

|

|

|

| |

| Core | Core material is used for the lamination process of manufacturing PCBs. This material is two- | |||||||

| sided laminate with copper on each side. The core is an internal layer that is etched. | ||||||||

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Layer 1: copper | Printed circuit board: An example PCB | |

|

|

|

|

|

|

| manufacturing process consists of the | ||

|

|

|

|

|

|

| Prepreg | following steps: | |

|

|

|

|

|

|

| Layer 2: GND | • A PCB consists of alternating layers of | |

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

| Core | core and prepreg stacked. | |

|

|

|

|

|

|

| • The finished PCB is heated and cured. | ||

| PCB |

|

|

|

|

| Layer 3: VCC | ||

|

|

|

|

|

| • The via holes are drilled. | |||

|

|

|

|

|

|

| |||

|

|

|

|

|

|

| Prepreg | ||

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

| Layer 4: copper | • Plating covers holes and outer surfaces. | |

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

| • Etching removes unwanted copper. |

|

| Example of a | • The PCB is tinned, coated with solder | ||||||

|

|

| a | ||||||

|

|

| mask, and | ||||||

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

Intel® 31154 133 MHz PCI Bridge Design Guide Design Guide | 7 |