|

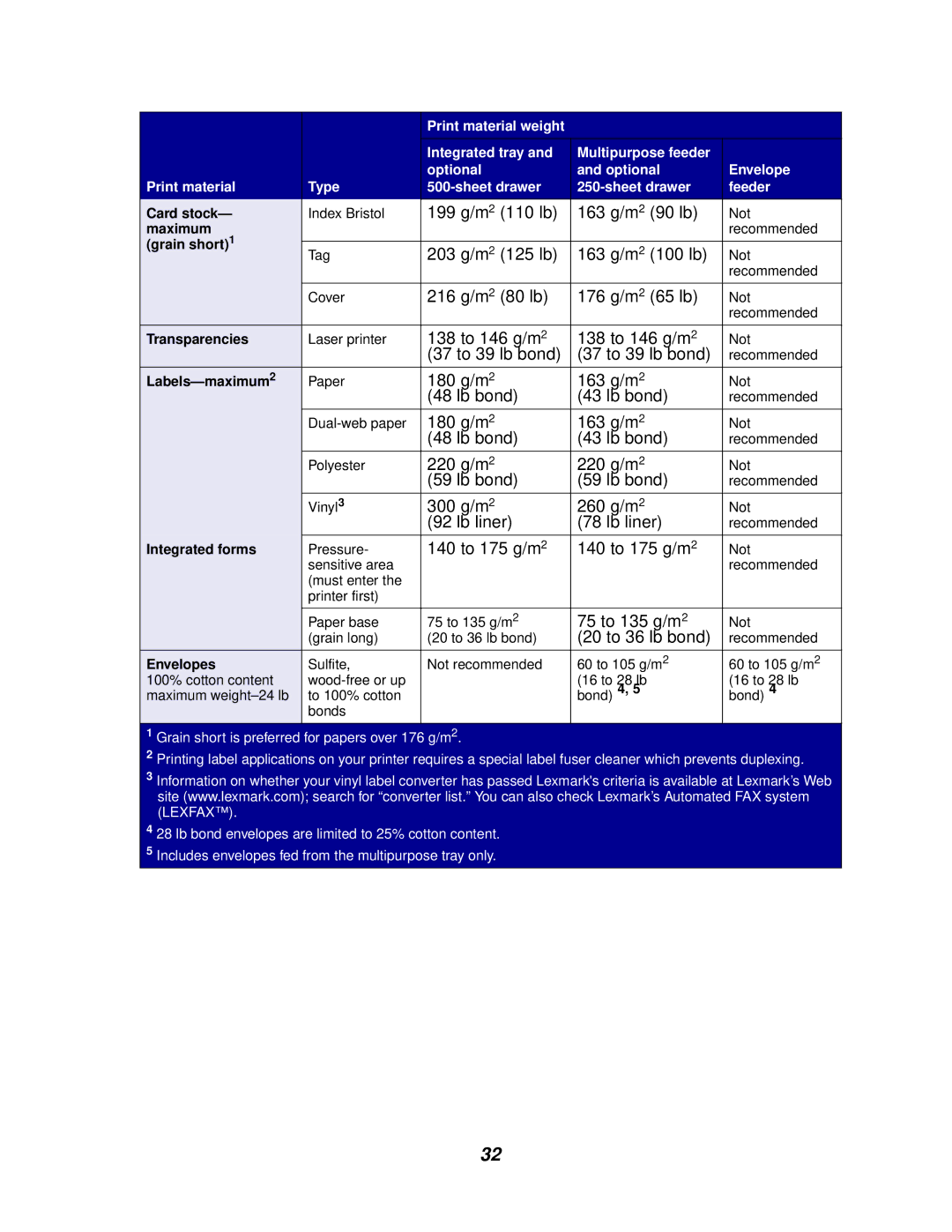

| Print material weight |

|

| |

|

| Integrated tray and | Multipurpose feeder |

| |

|

| optional | and optional | Envelope | |

Print material | Type | feeder | |||

Card stock— | Index Bristol | 199 g/m2 (110 lb) | 163 g/m2 (90 lb) | Not | |

maximum |

|

|

| recommended | |

(grain short)1 |

|

|

|

| |

Tag | 203 g/m2 (125 lb) | 163 g/m2 (100 lb) | Not | ||

| |||||

|

|

|

| recommended | |

|

|

|

|

| |

| Cover | 216 g/m2 (80 lb) | 176 g/m2 (65 lb) | Not | |

|

|

|

| recommended | |

Transparencies | Laser printer | 138 to 146 g/m2 | 138 to 146 g/m2 | Not | |

|

| (37 to 39 lb bond) | (37 to 39 lb bond) | recommended | |

| Paper | 180 g/m2 | 163 g/m2 | Not | |

|

| (48 lb bond) | (43 lb bond) | recommended | |

| 180 g/m2 | 163 g/m2 | Not | ||

|

| (48 lb bond) | (43 lb bond) | recommended | |

| Polyester | 220 g/m2 | 220 g/m2 | Not | |

|

| (59 lb bond) | (59 lb bond) | recommended | |

| Vinyl3 | 300 g/m2 | 260 g/m2 | Not | |

|

| (92 lb liner) | (78 lb liner) | recommended | |

Integrated forms | Pressure- | 140 to 175 g/m2 | 140 to 175 g/m2 | Not | |

| sensitive area |

|

| recommended | |

| (must enter the |

|

|

| |

| printer first) |

|

|

| |

|

|

|

|

| |

| Paper base | 75 to 135 g/m2 | 75 to 135 g/m2 | Not | |

| (grain long) | (20 to 36 lb bond) | (20 to 36 lb bond) | recommended | |

Envelopes | Sulfite, | Not recommended | 60 to 105 g/m2 | 60 to 105 g/m2 | |

100% cotton content |

| (16 to 28 lb | (16 to 28 lb | ||

maximum | to 100% cotton |

| bond) 4, 5 | bond) 4 | |

| bonds |

|

|

| |

|

|

|

|

|

1 Grain short is preferred for papers over 176 g/m2.

2 Printing label applications on your printer requires a special label fuser cleaner which prevents duplexing.

3 Information on whether your vinyl label converter has passed Lexmark's criteria is available at Lexmark’s Web site (www.lexmark.com); search for “converter list.” You can also check Lexmark’s Automated FAX system (LEXFAX™ ).

4 28 lb bond envelopes are limited to 25% cotton content.

5 Includes envelopes fed from the multipurpose tray only.

32