GENERAL SAFETY GUIDELINES

Before beginning the installation of the Liebert XDC, read all instructions, verify that all the parts are included, and check the nameplate to be sure the Liebert XDC voltage matches available utility power.

Follow all local codes.

! WARNING

Risk of electric shock. Can cause injury or death.

Disconnect all local and remote electric power supplies before working within.

! WARNING

Risk of unit falling over. Can cause death, injury and equipment damage.

The Liebert XDC is

! CAUTION

Risk of piping and component rupture. Can cause injury or equipment damage. Closing service valves may isolate liquid refrigerant, causing high pressure and rupture of piping. Do not close valves without following recommended procedures for repair, maintenance and replacement of components. Install pressure relief valves in field piping that may become isolated by service valves.

! WARNING

Risk of refrigerant system explosion or rupture from overpressurization. Can cause injury, death or equipment damage.

Installer must install a 400 psig pressure relief valve in each of the two

For systems requiring EU CE compliance, the pressure relief valves must be

! CAUTION

Risk of contact with hot surfaces. Can cause burn injury. The compressors and refrigerant discharge lines are extremely hot during unit operation. Allow sufficient time for the compressors and refrigerant discharge lines to cool before working within the unit cabinet. Use extreme caution and wear protective gloves and arm protection when working on or near hot compressor and discharge lines.

NOTE

This document shall be used together with site specific documentation and documentation for other parts of the system (heat rejection devices and cooling modules).

NOTE

Before any action that could cause a disturbance in the XD system’s cooling function is begun, the facility manager MUST be informed. In addition, after the action is taken and the work is finished, the facility manager MUST be informed.

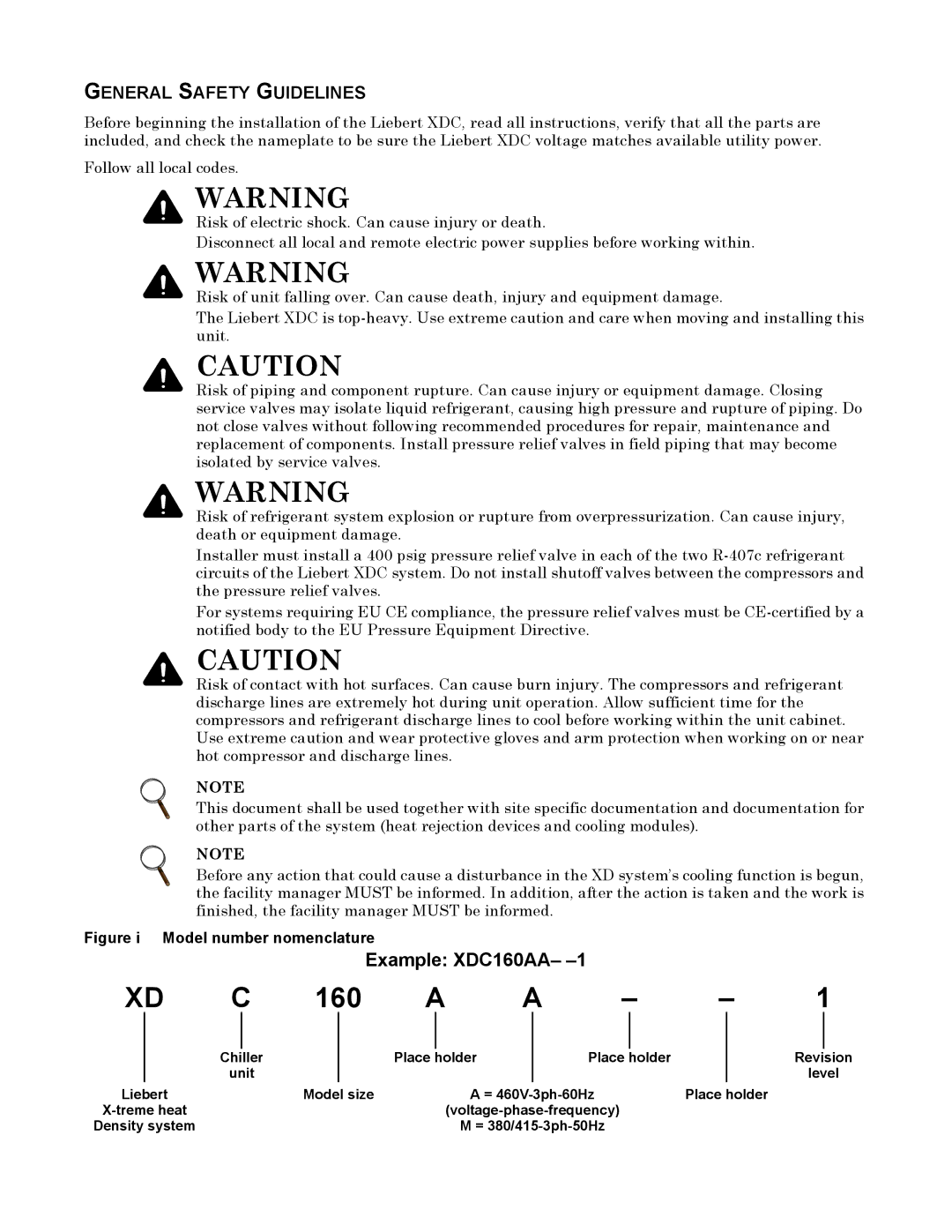

Figure i Model number nomenclature

|

|

|

|

| Example: XDC160AA– |

|

|

|

|

|

| |||||

XD | C | 160 | A | A | – | – | 1 | |||||||||

|

|

|

|

|

| Place |

| holder |

|

|

|

|

|

|

| |

|

| Chiller |

|

|

|

| Place holder |

|

| Revision | ||||||

|

| unit |

|

|

|

|

|

|

|

|

|

|

| level | ||

Liebert |

|

| Model size |

|

|

| A = | Place holder |

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

| |||||

Density system |

|

|

|

|

|

|

| M = |

|

|

|

| ||||