Piping and Filling with Refrigerant:

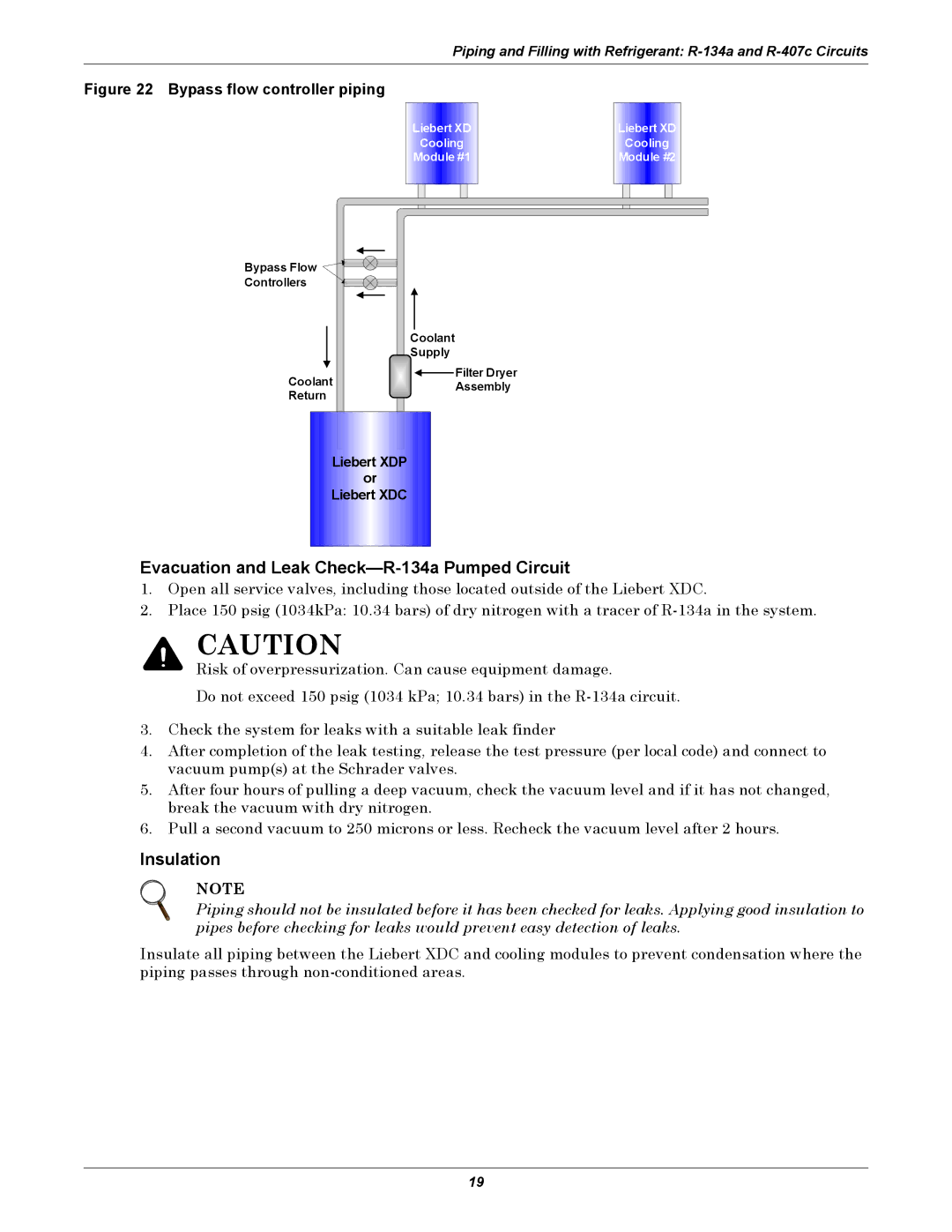

Figure 22 Bypass flow controller piping

Liebert XD

Cooling

Module #1

Bypass Flow ![]()

![]()

Controllers

Coolant

Supply

Filter Dryer

CoolantAssembly

Return

Liebert XD

Cooling

Module #2

Liebert XDP

or

Liebert XDC

Evacuation and Leak Check—R-134a Pumped Circuit

1.Open all service valves, including those located outside of the Liebert XDC.

2.Place 150 psig (1034kPa: 10.34 bars) of dry nitrogen with a tracer of

! CAUTION

Risk of overpressurization. Can cause equipment damage.

Do not exceed 150 psig (1034 kPa; 10.34 bars) in the

3.Check the system for leaks with a suitable leak finder

4.After completion of the leak testing, release the test pressure (per local code) and connect to vacuum pump(s) at the Schrader valves.

5.After four hours of pulling a deep vacuum, check the vacuum level and if it has not changed, break the vacuum with dry nitrogen.

6.Pull a second vacuum to 250 microns or less. Recheck the vacuum level after 2 hours.

Insulation

NOTE

Piping should not be insulated before it has been checked for leaks. Applying good insulation to pipes before checking for leaks would prevent easy detection of leaks.

Insulate all piping between the Liebert XDC and cooling modules to prevent condensation where the piping passes through

19