Piping and Filling with Refrigerant:

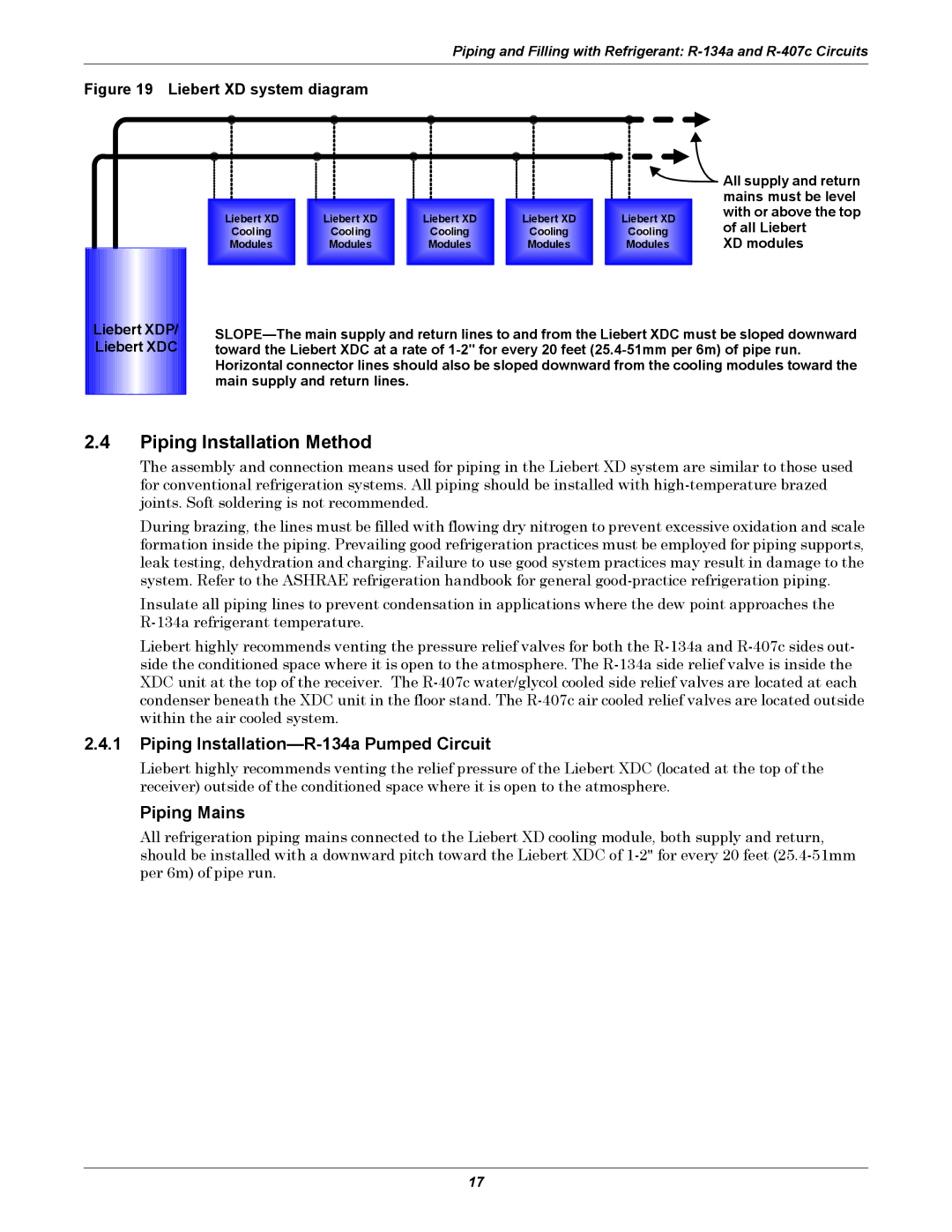

Figure 19 Liebert XD system diagram

Liebert XDP/ Liebert XDC

|

|

|

|

| All supply and return | |

|

|

|

|

| mains must be level | |

Liebert XD | Liebert XD | Liebert XD | Liebert XD | Liebert XD | with or above the top | |

of all Liebert | ||||||

Cooling | Cooling | Cooling | Cooling | Cooling | ||

Modules | Modules | Modules | Modules | Modules | XD modules |

2.4Piping Installation Method

The assembly and connection means used for piping in the Liebert XD system are similar to those used for conventional refrigeration systems. All piping should be installed with

During brazing, the lines must be filled with flowing dry nitrogen to prevent excessive oxidation and scale formation inside the piping. Prevailing good refrigeration practices must be employed for piping supports, leak testing, dehydration and charging. Failure to use good system practices may result in damage to the system. Refer to the ASHRAE refrigeration handbook for general

Insulate all piping lines to prevent condensation in applications where the dew point approaches the

Liebert highly recommends venting the pressure relief valves for both the

2.4.1Piping Installation—R-134a Pumped Circuit

Liebert highly recommends venting the relief pressure of the Liebert XDC (located at the top of the receiver) outside of the conditioned space where it is open to the atmosphere.

Piping Mains

All refrigeration piping mains connected to the Liebert XD cooling module, both supply and return, should be installed with a downward pitch toward the Liebert XDC of

17