Piping and Filling with Refrigerant:

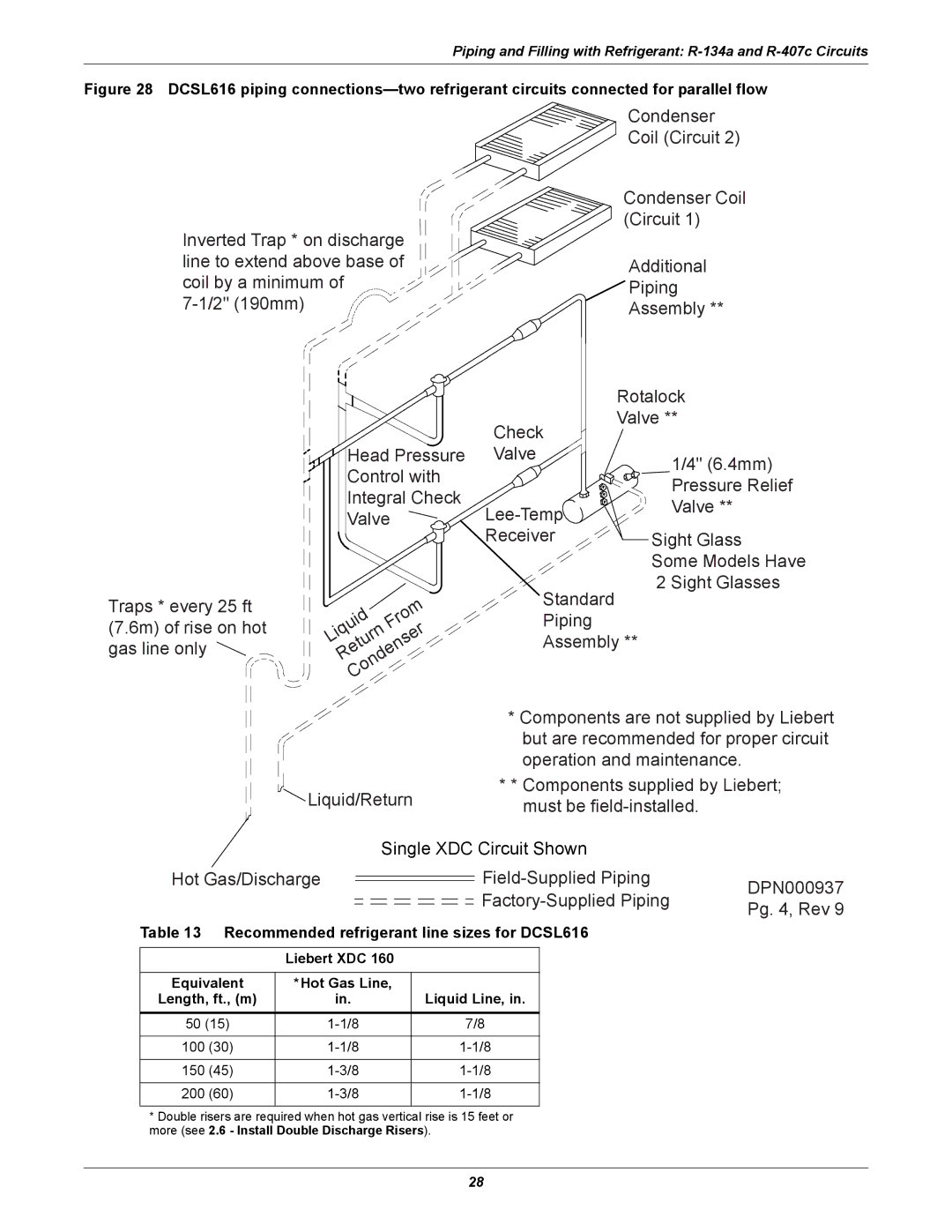

Figure 28 DCSL616 piping connections—two refrigerant circuits connected for parallel flow

Inverted Trap * on discharge line to extend above base of coil by a minimum of

Condenser Coil (Circuit 2)

Condenser Coil (Circuit 1)

Additional Piping Assembly **

Traps * every 25 ft (7.6m) of rise on hot gas line only

Head Pressure Control with Integral Check Valve

|

|

|

|

|

|

|

| m | |

|

|

| d |

| o |

| |||

|

|

|

| r |

| ||||

|

| i |

|

|

|

| |||

| u |

|

| F |

| r | |||

q |

|

| n |

|

| ||||

i |

|

|

|

| e | ||||

L |

|

|

| r |

|

| |||

|

| u |

| s | |||||

|

| t |

|

| n |

| |||

|

| e |

|

| e |

|

| ||

R |

|

| d |

|

|

| |||

|

|

|

| n |

|

|

| ||

|

|

| o |

|

|

|

| ||

|

| C |

|

|

|

|

|

| |

| Rotalock |

Check | Valve ** |

| |

Valve | 1/4" (6.4mm) |

| |

| Pressure Relief |

Valve ** | |

| |

Receiver | Sight Glass |

| Some Models Have |

2 Sight Glasses

Standard

Piping Assembly **

* Components are not supplied by Liebert

|

|

| but are recommended for proper circuit | ||

|

|

| operation and maintenance. |

| |

| Liquid/Return | * * Components supplied by Liebert; | |||

| must be |

| |||

|

|

|

| ||

| Single XDC Circuit Shown |

| |||

Hot Gas/Discharge | DPN000937 | ||||

|

|

| |||

|

|

| Pg. 4, Rev 9 | ||

|

|

|

|

| |

Table 13 Recommended refrigerant line sizes for DCSL616 |

| ||||

|

|

|

|

|

|

| Liebert XDC 160 |

|

|

| |

|

|

|

|

|

|

Equivalent | *Hot Gas Line, |

|

|

|

|

Length, ft., (m) | in. |

| Liquid Line, in. |

|

|

50 (15) |

| 7/8 |

|

| |

|

|

|

|

|

|

100 (30) |

|

|

| ||

|

|

|

|

|

|

150 (45) |

|

|

| ||

|

|

|

|

|

|

200 (60) |

|

|

| ||

|

|

|

|

|

|

*Double risers are required when hot gas vertical rise is 15 feet or more (see 2.6 - Install Double Discharge Risers).

28