Maintenance

8.0MAINTENANCE

The Liebert XD system components require little maintenance when proper fluid levels are main- tained and proper startup and operation procedures are followed. The following tasks should be per- formed at the intervals stated:

1.Check sight glass level of receiver on all circuits every

2.Check system for leaks every

8.1Fluorinated Greenhouse Gas Requirements

Stationary air conditioning, refrigeration, heat pump equipments and stationary fire protection sys- tems in the European Community market and operating with fluorinated greenhouse gases

The

Refer to the full regulation for additional details.

8.2Air Cooled Condenser

Restricted airflow through the condenser coil will reduce the operating efficiency of the unit and can result in high compressor head pressure and loss of cooling.

Clean the condenser coil of all debris that will inhibit air flow. This can be done with compressed air or commercial coil cleaner. Check for bent or damaged coil fins and repair as necessary. In winter, do not permit snow to accumulate around the sides or underneath the condenser.

Check all refrigerant lines and capillaries for vibration isolation. Support as necessary. Visually inspect all refrigerant lines for signs of oil leaks.

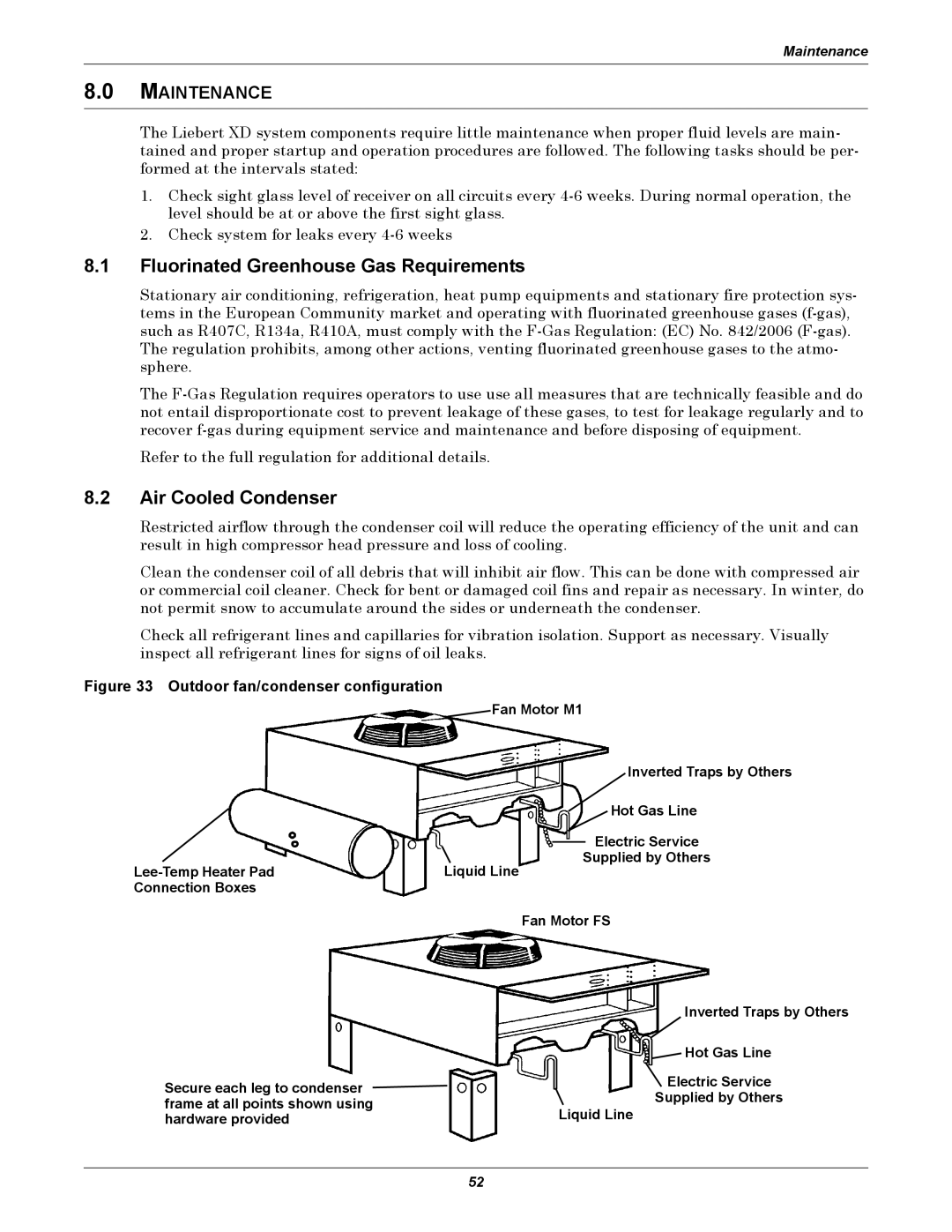

Figure 33 Outdoor fan/condenser configuration

Connection Boxes

Secure each leg to condenser frame at all points shown using hardware provided

![]() Fan Motor M1

Fan Motor M1

Inverted Traps by Others

Hot Gas Line

Electric Service

Supplied by Others

Liquid Line

Fan Motor FS

Inverted Traps by Others

![]() Hot Gas Line

Hot Gas Line

![]() Electric Service

Electric Service

Supplied by Others

Liquid Line

52