Checklist for Liebert XDC Startup

4.1System Refrigerant Charges Over 35 lb. (15.9kg) Require Additional Oil

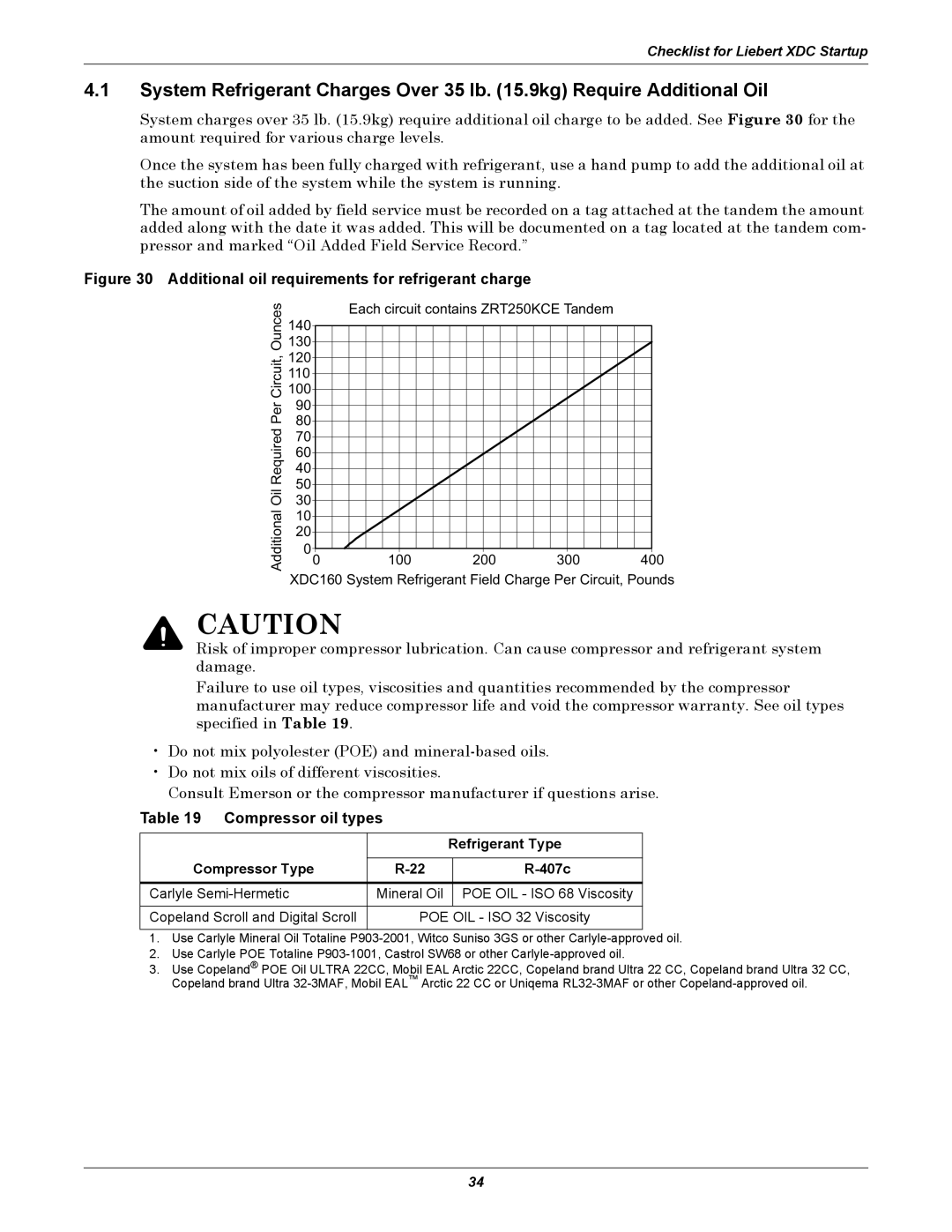

System charges over 35 lb. (15.9kg) require additional oil charge to be added. See Figure 30 for the amount required for various charge levels.

Once the system has been fully charged with refrigerant, use a hand pump to add the additional oil at the suction side of the system while the system is running.

The amount of oil added by field service must be recorded on a tag attached at the tandem the amount added along with the date it was added. This will be documented on a tag located at the tandem com- pressor and marked “Oil Added Field Service Record.”

Figure 30 Additional oil requirements for refrigerant charge

Ounces | 140 | Each circuit contains ZRT250KCE Tandem |

| |||

|

|

|

| |||

130 |

|

|

|

| ||

Circuit, | 120 |

|

|

|

| |

110 |

|

|

|

| ||

100 |

|

|

|

| ||

Per | 90 |

|

|

|

| |

80 |

|

|

|

| ||

Required |

|

|

|

| ||

70 |

|

|

|

| ||

60 |

|

|

|

| ||

40 |

|

|

|

| ||

50 |

|

|

|

| ||

Oil |

|

|

|

| ||

30 |

|

|

|

| ||

Additional | 10 |

|

|

|

| |

20 |

|

|

|

| ||

0 | 100 | 200 | 300 | 400 | ||

0 | ||||||

XDC160 System Refrigerant Field Charge Per Circuit, Pounds | ||||||

| ||||||

! CAUTION

Risk of improper compressor lubrication. Can cause compressor and refrigerant system damage.

Failure to use oil types, viscosities and quantities recommended by the compressor manufacturer may reduce compressor life and void the compressor warranty. See oil types specified in Table 19.

•Do not mix polyolester (POE) and

•Do not mix oils of different viscosities.

Consult Emerson or the compressor manufacturer if questions arise.

Table 19 Compressor oil types

|

| Refrigerant Type | |

Compressor Type |

|

|

|

|

| ||

|

|

|

|

Carlyle | Mineral Oil |

| POE OIL - ISO 68 Viscosity |

|

|

| |

Copeland Scroll and Digital Scroll | POE OIL - ISO 32 Viscosity | ||

|

|

|

|

1.Use Carlyle Mineral Oil Totaline

2.Use Carlyle POE Totaline

3.Use Copeland® POE Oil ULTRA 22CC, Mobil EAL Arctic 22CC, Copeland brand Ultra 22 CC, Copeland brand Ultra 32 CC, Copeland brand Ultra

34