OPERATION

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Idler Operational Exceptions

When the WELDING TERMINALS switch is in the “Welding Terminals Remotely Controlled” position, the idler will operate as follows:

a.When the triggering device (Amptrol, Arc Start Switch, etc.) is pressed, the engine will accelerate and operate at full speed provided a welding load is applied within approximately 15 seconds.

•If the triggering device remains pressed but no welding load is applied within approximately 15 seconds, the engine will return to low idle speed.

•If the triggering device is released or welding ceases, the engine will return to low idle speed after approximately 15 seconds.

8. HOUR METER

The hour meter displays the total time that the engine has been running. This meter is a useful indicator for scheduling preventive maintenance.

WELDER CONTROLS (Items 9 through 13 )

9. M WELD MODE & | OUTPUT CONTROL |

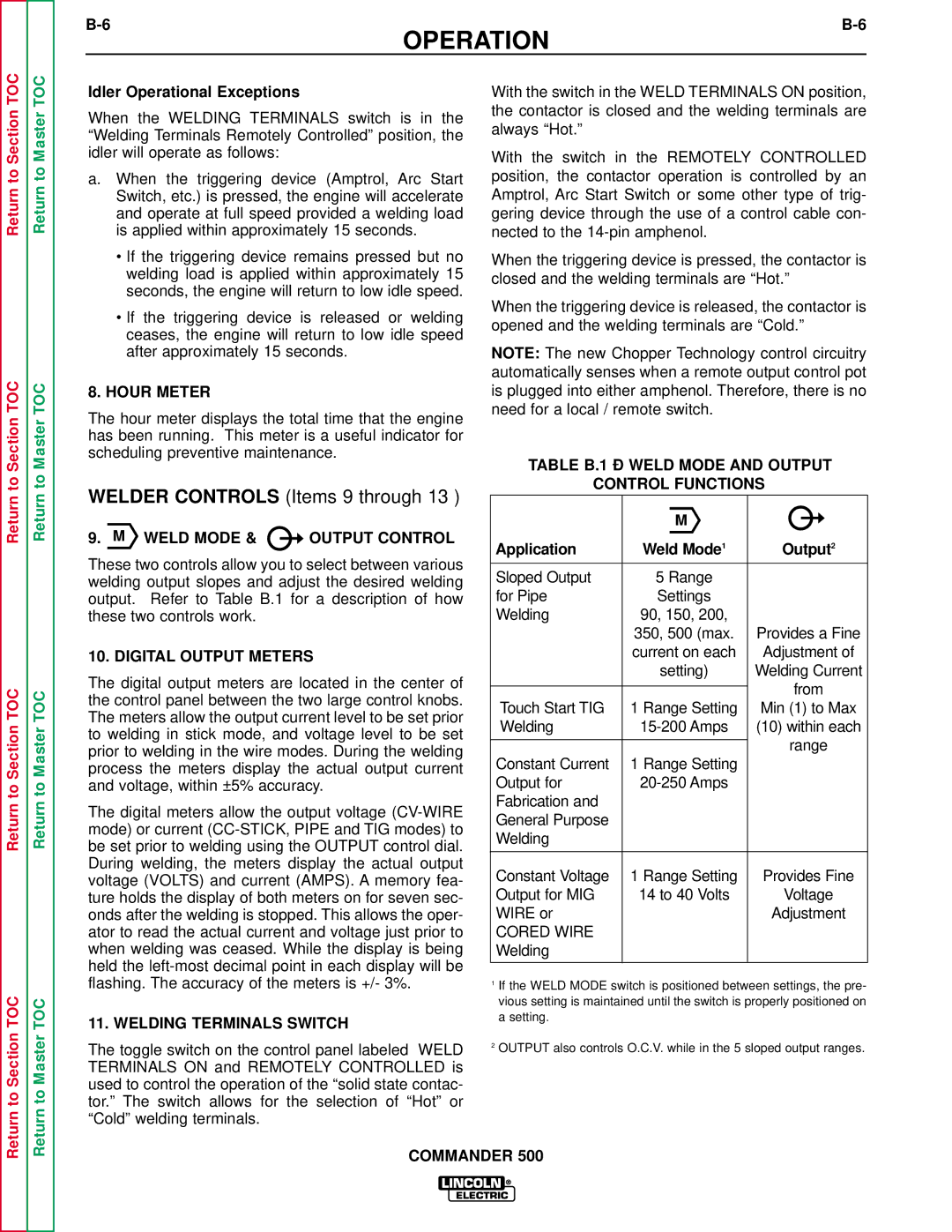

These two controls allow you to select between various welding output slopes and adjust the desired welding output. Refer to Table B.1 for a description of how these two controls work.

10. DIGITAL OUTPUT METERS

The digital output meters are located in the center of the control panel between the two large control knobs. The meters allow the output current level to be set prior to welding in stick mode, and voltage level to be set prior to welding in the wire modes. During the welding process the meters display the actual output current and voltage, within ±5% accuracy.

The digital meters allow the output voltage

11. WELDING TERMINALS SWITCH

The toggle switch on the control panel labeled WELD TERMINALS ON and REMOTELY CONTROLLED is used to control the operation of the “solid state contac- tor.” The switch allows for the selection of “Hot” or “Cold” welding terminals.

With the switch in the WELD TERMINALS ON position, the contactor is closed and the welding terminals are always “Hot.”

With the switch in the REMOTELY CONTROLLED position, the contactor operation is controlled by an Amptrol, Arc Start Switch or some other type of trig- gering device through the use of a control cable con- nected to the

When the triggering device is pressed, the contactor is closed and the welding terminals are “Hot.”

When the triggering device is released, the contactor is opened and the welding terminals are “Cold.”

NOTE: The new Chopper Technology control circuitry automatically senses when a remote output control pot is plugged into either amphenol. Therefore, there is no need for a local / remote switch.

TABLE B.1 – WELD MODE AND OUTPUT

CONTROL FUNCTIONS

| M |

| |

Application | Weld Mode1 | Output2 | |

|

|

| |

Sloped Output | 5 Range |

| |

for Pipe | Settings |

| |

Welding | 90, 150, 200, |

| |

| 350, 500 (max. | Provides a Fine | |

| current on each | Adjustment of | |

| setting) | Welding Current | |

|

| from | |

|

| ||

Touch Start TIG | 1 Range Setting | Min (1) to Max | |

Welding | (10) within each | ||

|

| range | |

Constant Current | 1 Range Setting | ||

| |||

Output for |

| ||

Fabrication and |

|

| |

General Purpose |

|

| |

Welding |

|

| |

|

|

| |

Constant Voltage | 1 Range Setting | Provides Fine | |

Output for MIG | 14 to 40 Volts | Voltage | |

WIRE or |

| Adjustment | |

CORED WIRE |

|

| |

Welding |

|

| |

|

|

|

1If the WELD MODE switch is positioned between settings, the pre- vious setting is maintained until the switch is properly positioned on a setting.

2OUTPUT also controls O.C.V. while in the 5 sloped output ranges.

COMMANDER 500