OPERATION

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

WIRE FEED (CONSTANT VOLTAGE) WELDING

Connect a wire feeder to the Commander 500 and set welder controls according to the instructions listed ear- lier in this section.

The Commander 500 in the

Some recommended Innershield electrodes are: NR- 311,

Recommended Outershield electrodes are:

Some recommended solid wires for MIG welding are:

.035 (0.9 mm), .045 (1.1 mm) and .052 (1.3 mm),

For any electrodes, including the above recommenda- tions, the procedures should be kept within the rating of the machine. For additional electrode information, see Lincoln publications

AUXILIARY POWER OPERATION

Start the engine and set the IDLER control switch to the desired operating mode. Full power is available regardless of the welding control settings, if no welding current is being drawn.

The auxiliary power of the Commander consists of two 20

50

120VAC operation.

The auxiliary power capacity is 12,000 watts of 60 Hz, single phase power. The auxiliary power capacity rating in watts is equivalent to

± 10% at all loads up to rated capacity.

NOTE: The 120/240V receptacle has two 120V out- puts of different phases and cannot be paralleled.

The auxiliary power receptacles should only be used with

The current rating of any plug used with the system must be at least equal to the current capacity of the associated receptacle.

SIMULTANEOUS WELDING AND AUXILIARY POWER LOADS

It must be noted that the above auxiliary power ratings are with no welding load. Simultaneous welding and power loads are specified in Table B.4. The permissi- ble currents shown assume that current is being drawn from either the 120 VAC or 240 VAC supply (not both at the same time).

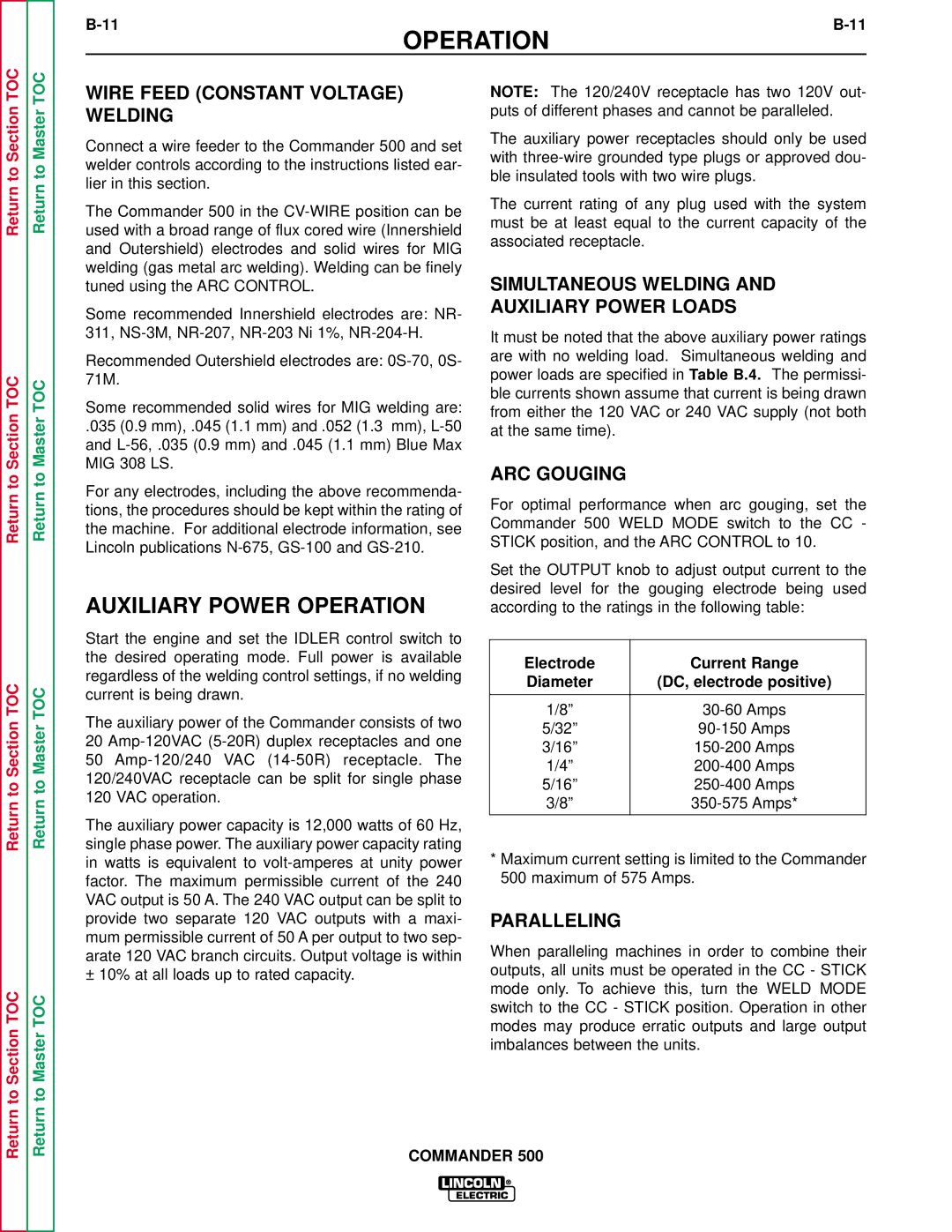

ARC GOUGING

For optimal performance when arc gouging, set the Commander 500 WELD MODE switch to the CC - STICK position, and the ARC CONTROL to 10.

Set the OUTPUT knob to adjust output current to the desired level for the gouging electrode being used according to the ratings in the following table:

Electrode | Current Range |

Diameter | (DC, electrode positive) |

|

|

1/8” | |

5/32” | |

3/16” | |

1/4” | |

5/16” | |

3/8” | |

|

|

*Maximum current setting is limited to the Commander 500 maximum of 575 Amps.

PARALLELING

When paralleling machines in order to combine their outputs, all units must be operated in the CC - STICK mode only. To achieve this, turn the WELD MODE switch to the CC - STICK position. Operation in other modes may produce erratic outputs and large output imbalances between the units.

COMMANDER 500