CommanderTM

Safety

California Proposition 65 Warnings

Electric Shock can kill

Welding Sparks can cause fire or explosion

Iii

Précautions DE Sûreté

Sûreté Pour Soudage a L’Arc

Master Table of Contents for ALL Sections

Table of Contents Installation Section

Installation

Technical Specifications Commander 500 K1639-1

Safety Precautions

Location / Ventilation

Storing

Stacking

High Temperature Operation

Lifting

Towing

High Altitude Operation

PRE-OPERATION Engine Service

Muffler Outlet Pipe

Spark Arrester

Auxiliary Power Receptacles

Standby Power Connections

Welding Output Cables

Machine Grounding

Company

Table of Contents Operation Section

Safety Instructions

Operation

Operating Instructions

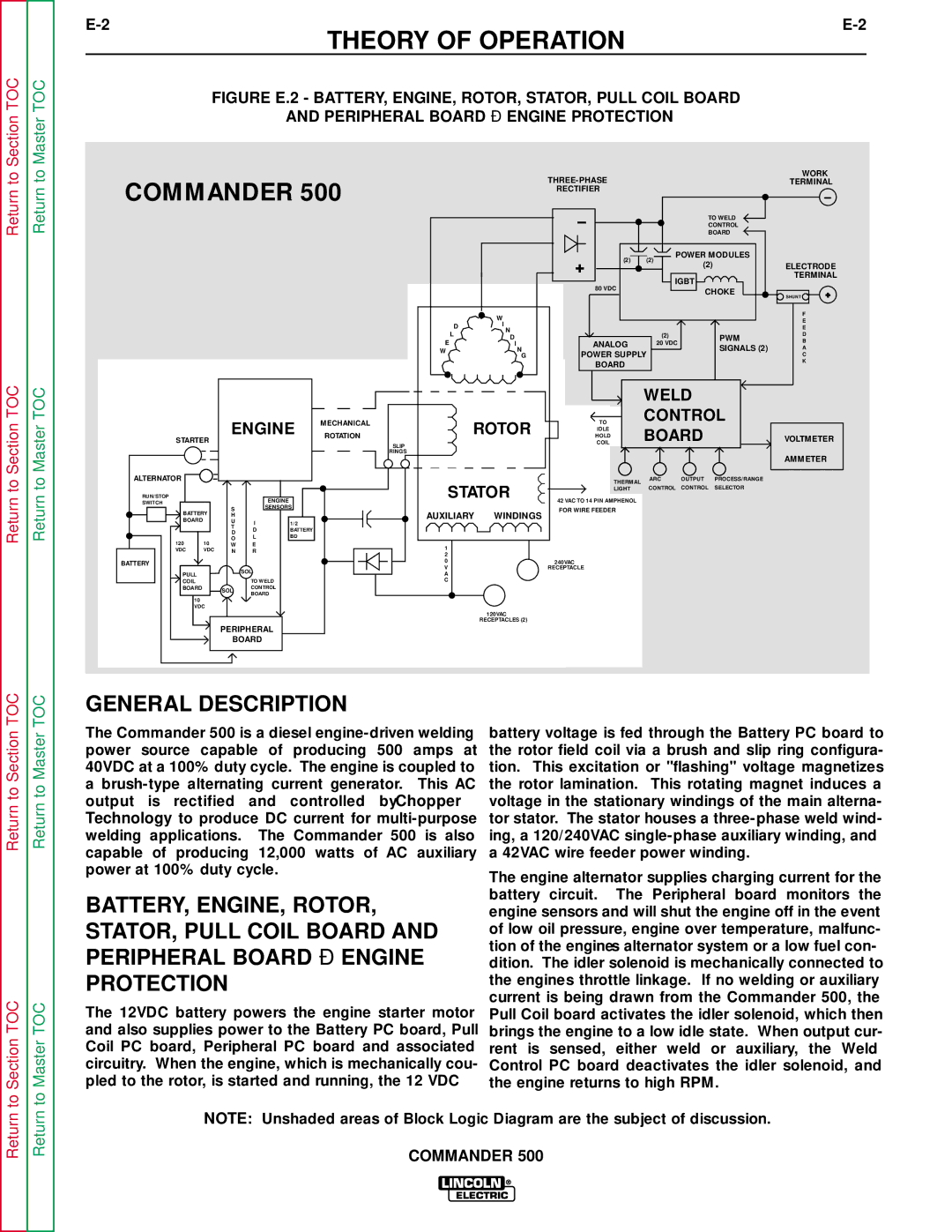

General Description

Design Features and Advantages

Recommended Applications

Controls and Settings

K1639-1 Commander 500 Standard Model

Welding Capability

RUN/STOP Switch

Idler Switch

Start Pushbutton

Fuel Level Gauge and Light

Weld Mode Output Control

Welding Terminals Switch

Table B.1 Weld Mode and Output Control Functions

Hour Meter

Auxiliary Power Controls

Engine Operation

Starting the Engine

BREAK-IN Period

Typical Fuel Consumption

Welder Operation

Stick Welding

Constant Current CC Welding

TIG Welding

Commander 500 Settings When Using the K799 HI-FREQ Unit

Commander 500 Settings When Using the K930-1 TIG Module

Table B.3 Typical Current RANGES1 for Tungsten ELECTRODES2

TIG Torch

Auxiliary Power Operation

Wire Feed Constant Voltage Welding

Simultaneous Welding and Auxiliary Power Loads

ARC Gouging

Extension Cord Recommendations

Permissible Permissible Auxiliary

Table of Contents Accessories Section

Accessories

OPTIONS/ACCESSORIES

Field Installed Options

Stick Welding Accessories

Semiautomatic Welding Accessories

Connection of Lincoln Electric Wire Feeders

Other Wire Feeders for the Commander

High Frequency Generators for TIG Applications

To Work Electrode Cable To Wire Feed Unit

ING CV

ING CV

ING CV

Figure C.5 Commander 500/LN-23P Connection Diagram

ING Terminals Always on

Table of Contents Maintenance Section

Maintenance

Routine and Periodic Maintenance

Engine Maintenance

Daily

Figure D.1 OIL Drain and Refill

Figure D.2 Fuel PRE-FILTER/WATER Separator Assembly

Fuel Filters

Figure D.3 Secondary Fuel Filter

AIR Filter

Maintenance

Frequency Maintenance Required

Table D.2 Engine Maintenance Parts Manufacturer Part Number

Battery Maintenance

Connecting a Battery Charger

WELDER/GENERATOR Maintenance

Figure D.5 Major Component Locations

Commander

Table of Contents Theory of Operation Section

Commander

Theory of Operation

Weld WINDINGS, RECTIFIER, Power Modules and Feedback

Analog Control Power Supply Board and Weld Control Board

Insulated Gate Bipolar Transistor Igbt Operation

Pulse Width Modulation

6E-6

Minimum Output

Maximum Output

External DC Solid State Inductor ARC Source Switch Diode

Chopper Technology Fundamentals

70-80VDC

Table of Contents

Troubleshooting & Repair Section

Section F-1

Troubleshooting & Repair

HOW to USE Troubleshooting Guide

PC Board Troubleshooting Procedures

PC Board can be damaged by static electricity

Troubleshooting Guide

Observe Safety Guidelines

Detailed in the beginning of this manual

Perform the Rotor Resistance

Justment Test

Function Problems

Charging Circuit Test

Engine Problems

Shutdown

Perform the Idler Solenoid

Problems Possible Areas

Symptoms Misadjustments Course of Action

Engine Starting Diagnostic Chart

START-UP and OCV Diagnostic Chart

Return

Case Cover Removal and Replacement Procedure

Description

Materials Needed

Case Cover Removal Replacement Procedure

Procedure

Figure F.1

Case Front Knobs Removal and Replacement Procedure

Removal

Power Module Capacitor Discharge Procedure

Procedure

Idler Solenoid Test

Test Description

Test Procedure

Figure F.5 Idler Solenoid Leads

Shutdown Solenoid Test

Figure F.6 Shutdown Solenoid Lead Terminals

Engine Throttle Adjustment Test

Figure F.7 Strobe Mark Location Mark Blower Paddle Here

Strobe-tach Method

Locking NUT

28F-28

Frequency Counter Method

Oscilloscope Method

Rotor Resistance Test

Test Procedure

Flashing and Rotor Voltage Test

10 11 12 13 14 15

Lead # 201A

Troubleshooting & Repair

Stator Voltage Test

Figure F.13 Front Control Panel Removal Screws

Troubleshooting & Repair

Auxiliary Power and Weld Windings Test

Auxiliary Leads #5B, #5E, #8, #9, #11, #12

Behind Panel

W6W1

Weld Winding Lead Connections

Analog Power Supply PC Board Voltage Test

Control Circuit Input Power

40F-40

J41

Analog Control Power Supply PC Board Test

Test Points Component Tested Voltage Reading

Output Rectifier Bridge Test

Perform the Power Module Capacitor Discharge Procedure

Troubleshooting & Repair

Figure F.20 Diode Lead Removal

Power Module Test

Temperature Switch

Power Module PC Board Diode Lead D4 Positive + Strap

W10

Check Igbt For Shorts

When all tests are complete

Check Diode Module

Charging Circuit Test

Figure F.24 Engine Alternator Location

#239 #281 #238

Scope Settings

Normal Open Circuit Voltage Waveform 115VAC Supply

High Idle no Load

15.8 ms Volts 50V5ms

Normal Open Circuit Voltage Waveform Stick

MAX TAP MAX Control POT High Idle no Load

Volts 50V5ms

Normal Weld Voltage Waveform Stick CC

Machine Loaded to 500 Amps AT 40 Volts

Volts 20V0.1ms

Normal Weld Voltage Waveform Wire CV

Normal TIG Mode Voltage Waveform

Loaded to 200A 16 Volts

Volts 10V50ms

Normal Open Circuit Voltage Waveform Wire CV TAP

MAX Control POT High Idle no Load

Shutdown Solenoid Removal and Replacement

Figure F Shutdown Solenoid Lead Connections

Reassembly

Figure F Shutdown Solenoid Linkage ARM Assembly

Description

Control Panel Removal Screws Front Green Ground Lead

Figure F Power Module Capacitor Lead Removal

Troubleshooting & Repair

Replacement Procedure

Description

Power Module PC Board Removal

Figure F.30 Power Module PC Board

Power Module PC Board Replacement

Diode Module Replacement

Diode Module Removal

Output Rectifier Bridge Diode Removal and Replacement

Refer to Figure F.32 Turn the engine off

Return Section TOC

Diode Stud Size Foot Pounds Inch Pounds

STATOR/ROTOR Removal and Replacement

Preparation and Lead Removal Procedure

Leads #229 #242D

Plug Fuel Lines Bolts

#200D #5P #201 #201A

Filter Field Diode Capacitor

Figure F.35 Brush Holder and Lead Removal

#232M

Figure F.37 Alternator Shroud Removal Screws Acoustical Foam

Figure F.38 Lift Frame and Associated Component Removal

Stator Removal Procedure

Figure F.39 Stator Removal

Rotor Removal Procedure

Reassembly Notes

Lead Reconnection Checklist

Engine

Output Panel and Control BOX

Welder CV Wire Output

Retest After Repair

Engine RPM

Welder DC Stick Output

Touch Start TIG Mode Output

Auxiliary Power Output

Electrical Diagrams

Table of Contents Electrical Diagrams Section

Electrical Diagrams

Schematic Complete Machine Commander

G3834

Schematic Battery PC Board

PC Board Assembly Battery PC Board

Return to Section

Schematic Chopper PC Board

PWM Input

PC Board Assembly Chopper PC Board

Return to Section Return to Section TOC

Schematic Peripheral PC Board

PC Board Assembly Peripheral PC Board

Return to Section

Schematic Power Supply Analog PC Board

PC Board Assembly Power Supply Analog PC Board

PC Board Reference QTY Designators Description

Schematic PULL-COIL PC Board

PC Board Assembly PULL-COIL PC Board

MOSFET/HEATSINK ASBLY,T12704-82&S1810

Schematic Weld Control PC Board Sheet

Electrical Diagrams

Electrical Diagrams

Electrical Diagrams

Electrical Diagrams

PC Board Assembly Weld Control PC Board

RESISTOR,SMD,METAL FILM,1/10W,150OHMS

SVM Error Reporting Form