Unit 1: Introduction

GENERAL DESCRIPTION

The MB200/201i are compact, transportable printers designed for frequent, but intermittant use. Their direct thermal print head not only allows high performance

Their ABS housing provides a durable,

THEORY OF OPERATION

When activated, the media is fed past the print head by an integrated drive train. The drive train is electric motor driven, coupled to a gear configuration located on the left side of the printer chassis. Kinetic energy is transferred to a platen roller which is the driving force of media movement. Paper guides within the chassis assembly ensure that the media remains properly positioned during the printing process and is fed unimpeded through an opening in the front.

A series of strategically located sensors sends signals to the processing unit. The processing unit in turn sends response signals to the various features based on programmed and received data.

Correct signals initiates print head activity.

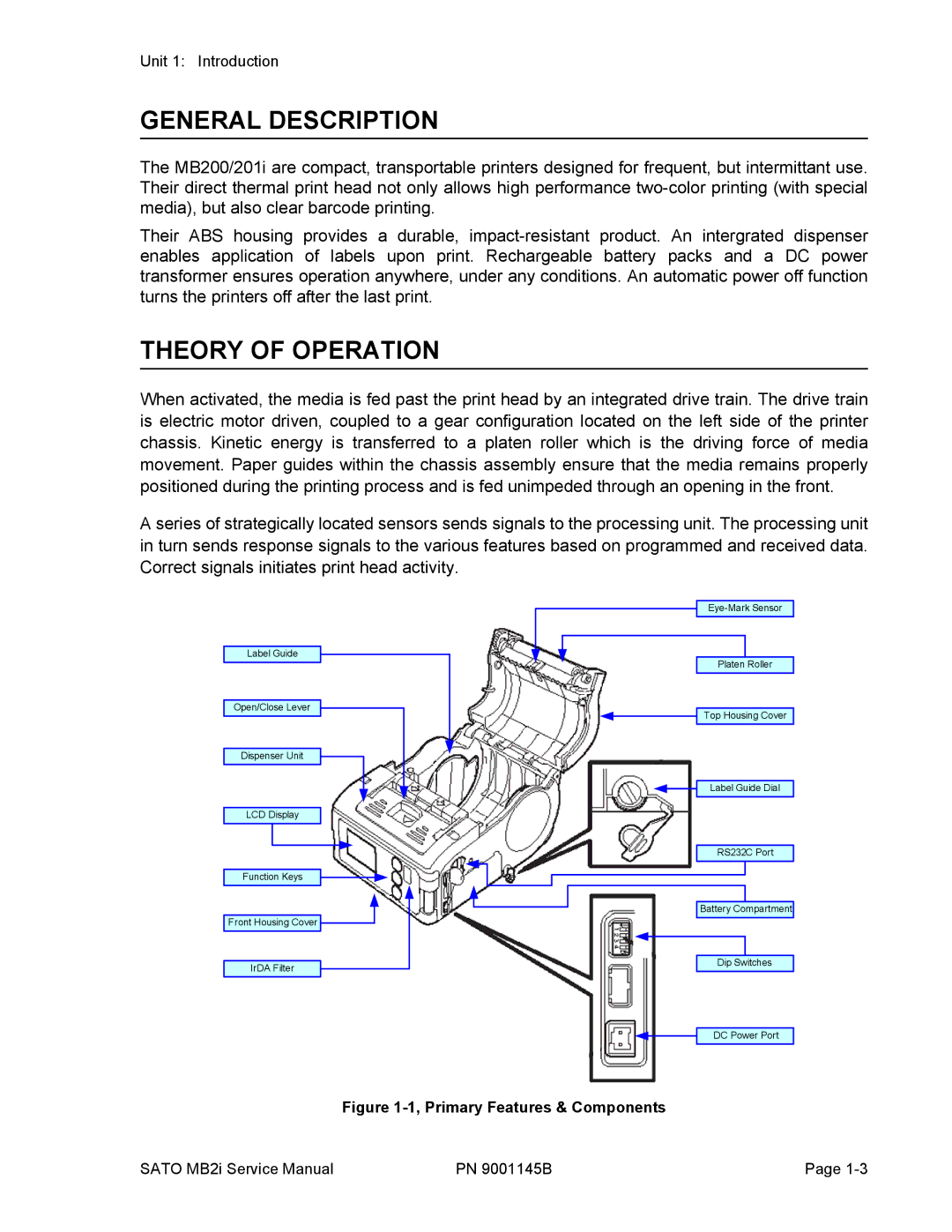

Label Guide

Open/Close Lever

Dispenser Unit

LCD Display

Function Keys

Front Housing Cover ![]()

![]()

IrDA Filter

Platen Roller

Top Housing Cover

Label Guide Dial

RS232C Port

Battery Compartment

Dip Switches

DC Power Port

Figure 1-1, Primary Features & Components

SATO MB2i Service Manual | PN 9001145B | Page |