Envelopes

Most envelopes will be suitable for your machine. However, some envelopes will have feed and

Envelopes can only be fed from Tray#1.

![]() Note

Note

We will not recommend a particular envelope because envelope manufacturers may change the envelope specifications. You are responsible for the quality and performance of the envelopes you use.

Before you put envelopes in the tray, check the following:

■Envelopes should have a lengthwise sealing flap.

■The sealing flaps should be folded crisply and correctly (irregularly cut or folded envelopes may cause paper jams).

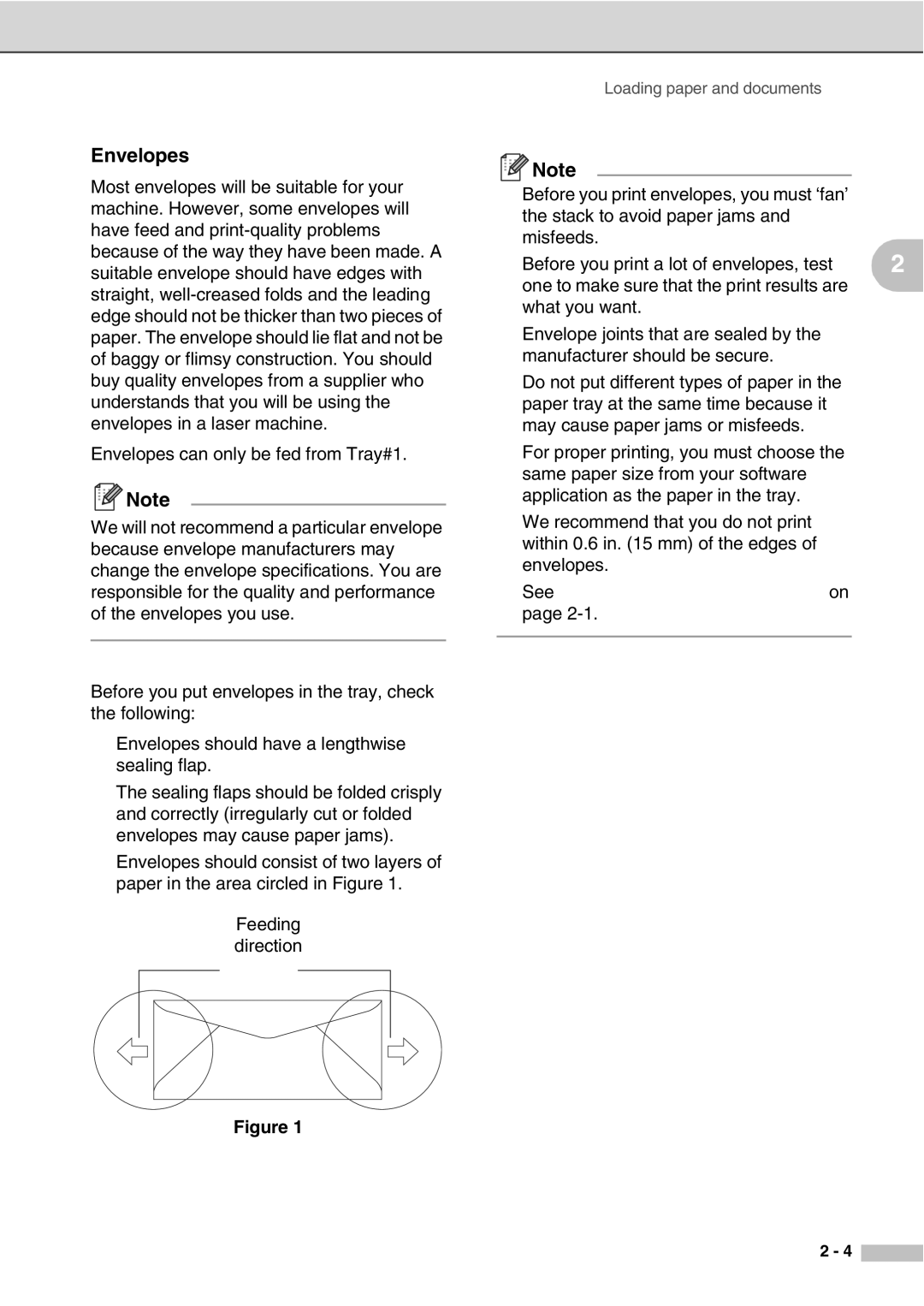

■Envelopes should consist of two layers of paper in the area circled in Figure 1.

Feeding direction

Figure 1

Loading paper and documents

![]() Note

Note

■Before you print envelopes, you must ‘fan’ the stack to avoid paper jams and misfeeds.

■ Before you print a lot of envelopes, test | 2 |

one to make sure that the print results are what you want.

■Envelope joints that are sealed by the manufacturer should be secure.

■Do not put different types of paper in the paper tray at the same time because it may cause paper jams or misfeeds.

■For proper printing, you must choose the same paper size from your software application as the paper in the tray.

■We recommend that you do not print within 0.6 in. (15 mm) of the edges of envelopes.

■See Acceptable paper and other media on page

2 - 4