Table

Number | Control/Indicator | Description | Section |

|

|

|

|

15 | PREV indicator | Green LED, lights when PREV button is pressed |

|

|

|

|

|

16 | FINE button | Voltage and Current Fine/Coarse adjustment control. Op- |

|

|

| erates as a toggle switch. In Fine mode, the VOLTAGE |

|

|

| and CURRENT encoders operate with high resolution and |

|

|

| in Coarse mode with lower resolution (approx. 6 turns). |

|

|

| Auxiliary function: Set units as Master or Slave in Ad- | 5.15.2 |

|

| vanced parallel operation. |

|

17 | FINE indicator | Green LED, lights when the unit is in Fine mode. |

|

|

|

|

|

18 | ALARM indicator | Red LED, blinks in case of fault detection. OVP, OTP |

|

|

| Foldback, Enable and AC fail detection will cause the |

|

|

| ALARM LED to blink. |

|

19 | AC Power switch | AC On/Off control. |

|

|

|

|

|

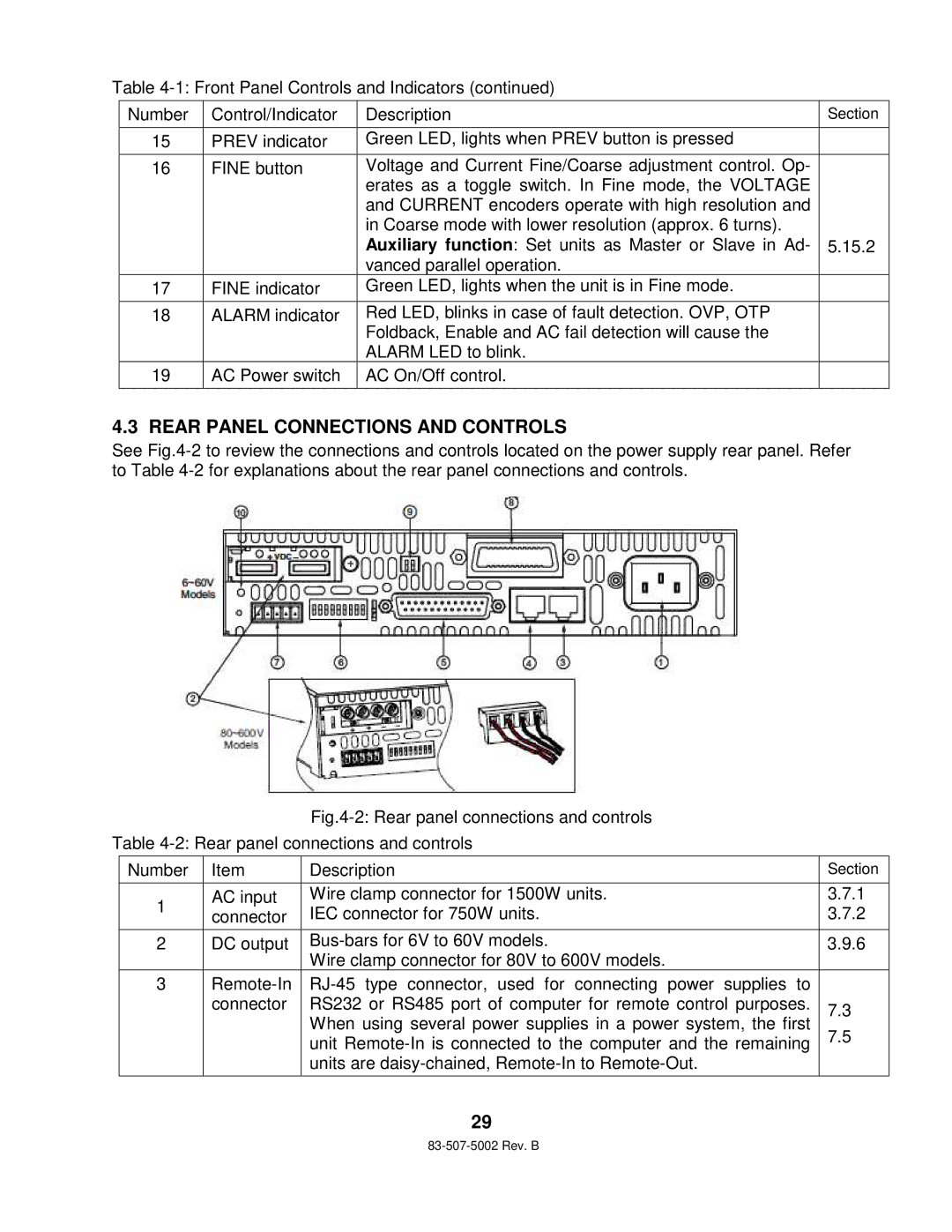

4.3 REAR PANEL CONNECTIONS AND CONTROLS

See

Fig.4-2: Rear panel connections and controls

Table

Number | Item | Description | Section | |

|

|

|

| |

1 | AC input | Wire clamp connector for 1500W units. | 3.7.1 | |

connector | IEC connector for 750W units. | 3.7.2 | ||

| ||||

|

|

|

| |

2 | DC output | 3.9.6 | ||

|

| Wire clamp connector for 80V to 600V models. |

| |

3 |

| |||

| connector | RS232 or RS485 port of computer for remote control purposes. | 7.3 | |

|

| When using several power supplies in a power system, the first | ||

|

| 7.5 | ||

|

| unit | ||

|

|

| ||

|

| units are |

| |

|

|

|

|

29