APPENDIX 1 SPECIFICATIONS | |

| A1.3 Media |

|

|

A1.3.1 | Media Type (Cont.) |

|

|

| |

|

|

|

|

| Unit: mm+(inch) |

|

|

|

|

|

|

| ? | Label dispensing mode | Batch mode |

| Strip mode |

| Item |

|

|

|

|

| @Width including backing paper | 20 to 112 (0.8 to 4.4) | |||

| ALabel width |

| Min. 17 (0.7) | ||

| BLabel pitch | 12 to 999 (0.5 to 39.3) |

| 12 to 999 (0.5 to 39.3) | |

|

| 10 ips: 25.4 to 999 mm (1 to 39.3) | |||

| CLabel length | Min. 10 (0.4) |

| Min. 10 (0.4) | |

|

| 10 ips: Min. 23.4 (0.9) | |||

| DGap length (or black mark length) | 2 to 20 (0.08 to 0.8) | |||

| Black mark width |

| Min. 12 (0.5) | ||

| Thickness | 0.13 to 0.18 (0.005 to 0.007) | |||

| Max. outer roll diameter | φ200 (Reference value, See NOTE 6.) | |||

| Roll direction | Inside rolled paper is recommended. | |||

| Inner core diameter | 76.2±0.3 (3±0.01) (Reference value) | |||

NOTES:

1.To ensure print quality and print head life use only TOSHIBA TEC approved media.

2.For the backing paper Glassine paper 7K white or equivalent should be used. Also, the light transmission rate of the backing paper should be 22% or above.

3.When perforating the media, it should be done from the print side to the reverse side.

4.Ink used for

5.The reflectance of the black mark should be 10% or less when the wavelength is 950nm.

6.As this printer does not have a label holder, this figure is a guide for the system integrator using this printer. When the outer roll diameter of the labels being used is 200 mm or less, a hanging type supply holder similar to the type used in TEC desktop thermal printer’s will work correctly. When the outer roll diameter exceeds 200 mm, the label holder should have mechanisms, such as bearings, a damper, etc. to reduce the tension on the label. In any case, prior to actual operation, please be sure to test all practical conditions including the labels, system, etc. and confirm there is no problem.

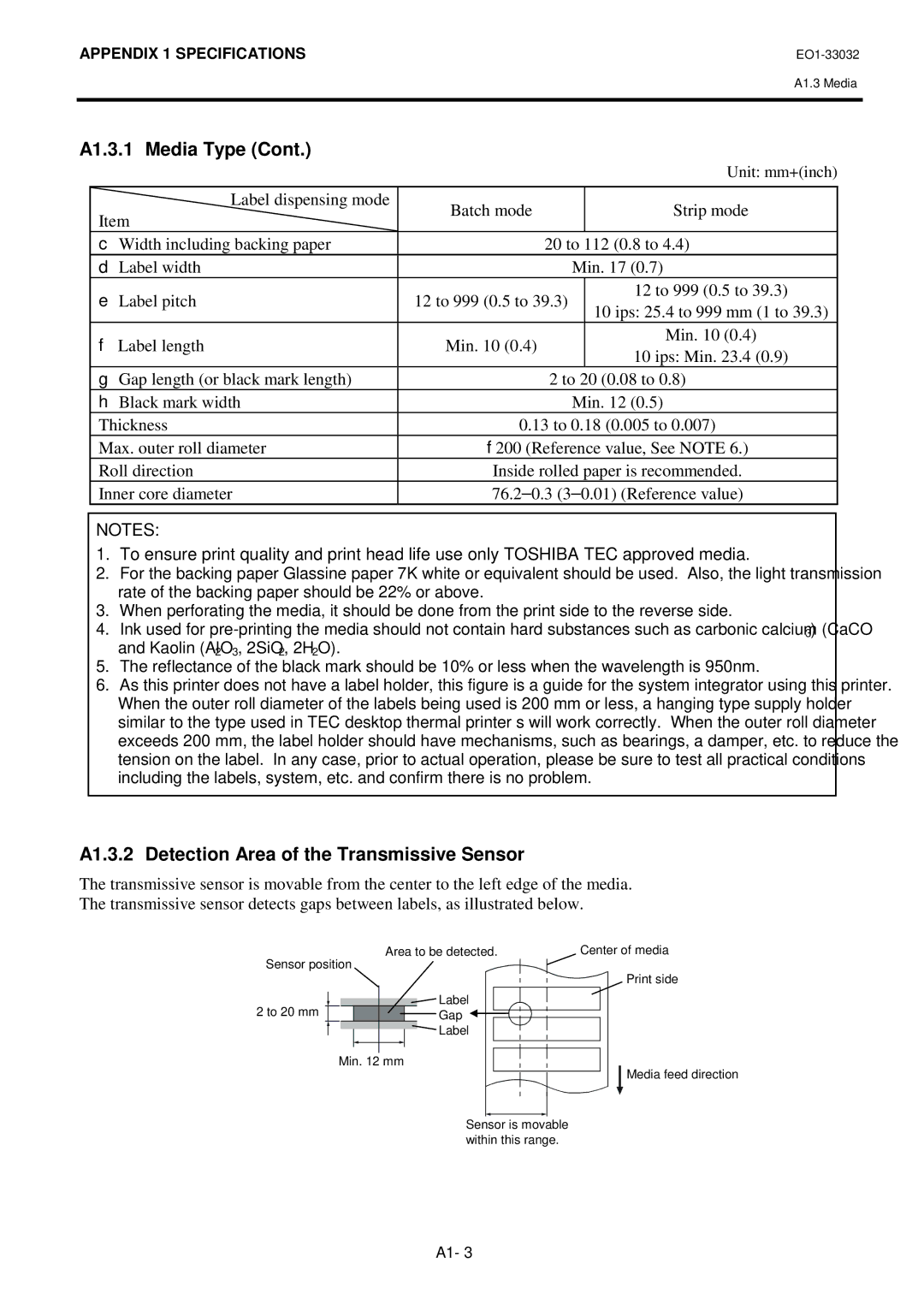

A1.3.2 Detection Area of the Transmissive Sensor

The transmissive sensor is movable from the center to the left edge of the media.

The transmissive sensor detects gaps between labels, as illustrated below.

|

|

|

|

|

| Area to be detected. |

|

|

| Center of media | |||||||||||||||||

Sensor position |

|

|

|

|

|

|

|

|

|

| Print side | ||||||||||||||||

|

|

|

| ||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

2 to 20 mm |

|

|

|

|

|

|

|

|

|

| Label |

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

| Gap |

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

| Label |

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

| Min. 12 mm |

|

|

|

|

|

|

|

|

|

|

| Media feed direction | ||||||||||||

|

|

|

|

|

| ||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

| Sensor is movable |

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

| within this range. |

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A1- 3