E6581160

Note 1. Capacity is calculated at 220V for the 240V models, at 440V for the 500V models and at 575V for the 600V models. Note 2. Indicates rated output current setting when the PWM carrier frequency (parameter F300) is 4kHz or less. When

exceeding 4kHz, the rated output current setting is indicated in the parentheses. It needs to be further reduced for PWM carrier frequencies above 12 kHz.

The rated output current is reduced even further for 500V models with a supply voltage of 480V or more. The default setting of the PWM carrier frequency is 12kHz.

Note 3. Maximum output voltage is the same as the input voltage. Note 4. ±10% when the inverter is used continuously (load of 100%).

Note 5. If you are using 600V model, be sure to connect an input reactor (ACL).

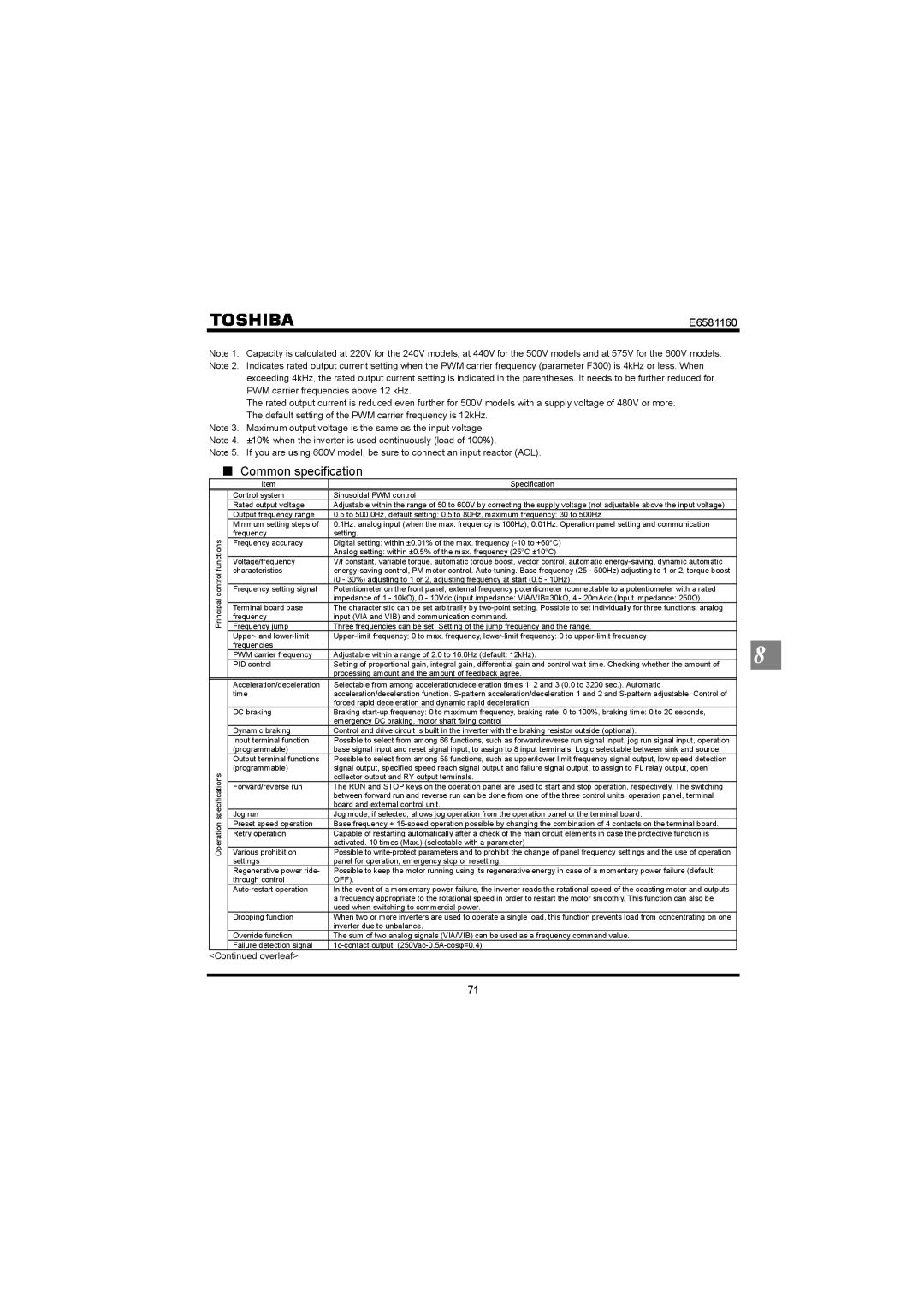

QCommon specification

| Item | Specification |

|

|

| Control system | Sinusoidal PWM control |

|

|

| Rated output voltage | Adjustable within the range of 50 to 600V by correcting the supply voltage (not adjustable above the input voltage) |

|

|

| Output frequency range | 0.5 to 500.0Hz, default setting: 0.5 to 80Hz, maximum frequency: 30 to 500Hz |

|

|

| Minimum setting steps of | 0.1Hz: analog input (when the max. frequency is 100Hz), 0.01Hz: Operation panel setting and communication |

|

|

functions | frequency | setting. |

|

|

Frequency accuracy | Digital setting: within ±0.01% of the max. frequency |

|

| |

| Analog setting: within ±0.5% of the max. frequency (25°C ±10°C) |

|

| |

| Voltage/frequency | V/f constant, variable torque, automatic torque boost, vector control, automatic |

|

|

control | characteristics |

|

| |

| (0 - 30%) adjusting to 1 or 2, adjusting frequency at start (0.5 - 10Hz) |

|

| |

| Frequency setting signal | Potentiometer on the front panel, external frequency potentiometer (connectable to a potentiometer with a rated |

|

|

Principal |

| impedance of 1 - 10kΩ), 0 - 10Vdc (input impedance: VIA/VIB=30kΩ, 4 - 20mAdc (Input impedance: 250Ω). |

|

|

Terminal board base | The characteristic can be set arbitrarily by |

|

| |

| frequency | input (VIA and VIB) and communication command. |

|

|

| Frequency jump | Three frequencies can be set. Setting of the jump frequency and the range. |

|

|

| Upper- and |

|

| |

| frequencies |

|

| 8 |

| PWM carrier frequency | Adjustable within a range of 2.0 to 16.0Hz (default: 12kHz). |

| |

| PID control | Setting of proportional gain, integral gain, differential gain and control wait time. Checking whether the amount of |

| |

|

| processing amount and the amount of feedback agree. |

|

|

| Acceleration/deceleration | Selectable from among acceleration/deceleration times 1, 2 and 3 (0.0 to 3200 sec.). Automatic |

|

|

| time | acceleration/deceleration function. |

|

|

|

| forced rapid deceleration and dynamic rapid deceleration |

|

|

| DC braking | Braking |

|

|

|

| emergency DC braking, motor shaft fixing control |

|

|

| Dynamic braking | Control and drive circuit is built in the inverter with the braking resistor outside (optional). |

|

|

| Input terminal function | Possible to select from among 66 functions, such as forward/reverse run signal input, jog run signal input, operation |

|

|

| (programmable) | base signal input and reset signal input, to assign to 8 input terminals. Logic selectable between sink and source. |

|

|

| Output terminal functions | Possible to select from among 58 functions, such as upper/lower limit frequency signal output, low speed detection |

|

|

specifications | (programmable) | signal output, specified speed reach signal output and failure signal output, to assign to FL relay output, open |

|

|

| collector output and RY output terminals. |

|

| |

Jog run | Jog mode, if selected, allows jog operation from the operation panel or the terminal board. |

|

| |

| Forward/reverse run | The RUN and STOP keys on the operation panel are used to start and stop operation, respectively. The switching |

|

|

|

| between forward run and reverse run can be done from one of the three control units: operation panel, terminal |

|

|

|

| board and external control unit. |

|

|

|

|

|

|

|

Operation | Preset speed operation | Base frequency + |

| |

Various prohibition | Possible to |

|

| |

| Retry operation | Capable of restarting automatically after a check of the main circuit elements in case the protective function is |

|

|

|

| activated. 10 times (Max.) (selectable with a parameter) |

|

|

| settings | panel for operation, emergency stop or resetting. |

|

|

| Regenerative power ride- | Possible to keep the motor running using its regenerative energy in case of a momentary power failure (default: |

|

|

| through control | OFF). |

|

|

| In the event of a momentary power failure, the inverter reads the rotational speed of the coasting motor and outputs |

|

| |

|

| a frequency appropriate to the rotational speed in order to restart the motor smoothly. This function can also be |

|

|

|

| used when switching to commercial power. |

|

|

| Drooping function | When two or more inverters are used to operate a single load, this function prevents load from concentrating on one |

|

|

|

| inverter due to unbalance. |

|

|

| Override function | The sum of two analog signals (VIA/VIB) can be used as a frequency command value. |

|

|

| Failure detection signal |

|

|

<Continued overleaf>

71