5.4OVEN SYSTEMS

Right Lock Motor Assembly |

| e. | Select “Top Oven.” | |

The right lock motor assembly consists of a motor, |

| f. | Select “Mags.” For Gen 1 ovens, the Cook- | |

|

| Wheel must not be in the Off position. | ||

locking mechanism for the right side of the Speed- |

|

| ||

|

|

| ||

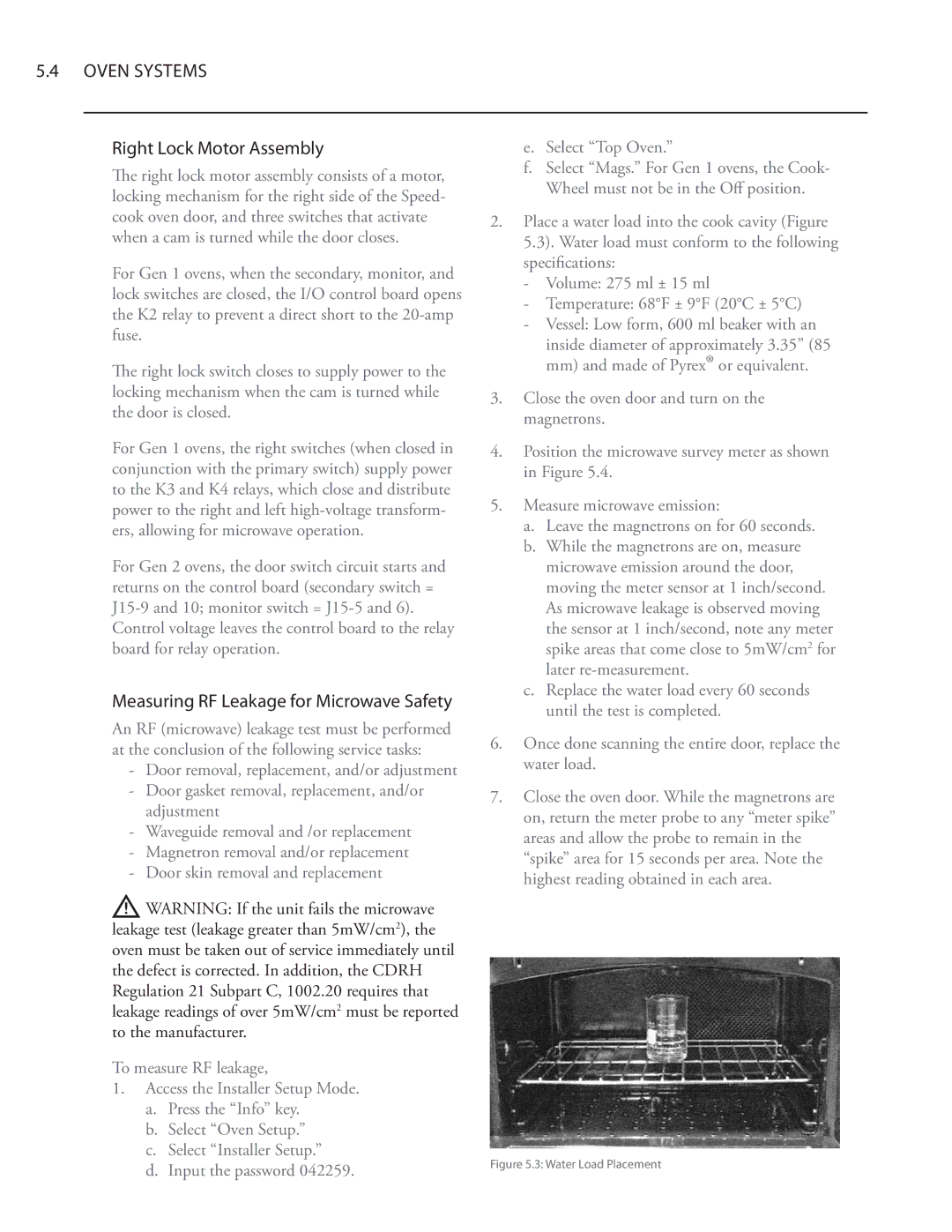

cook oven door, and three switches that activate | 2. | Place a water load into the cook cavity (Figure | ||

when a cam is turned while the door closes. |

| 5.3). Water load must conform to the following | ||

For Gen 1 ovens, when the secondary, monitor, and |

| specifications: | ||

| - | Volume: 275 ml ± 15 ml | ||

lock switches are closed, the I/O control board opens |

| |||

| - | Temperature: 68°F ± 9°F (20°C ± 5°C) | ||

the K2 relay to prevent a direct short to the |

| |||

| - | Vessel: Low form, 600 ml beaker with an | ||

fuse. |

| |||

|

| inside diameter of approximately 3.35” (85 | ||

|

|

| ||

The right lock switch closes to supply power to the |

|

| mm) and made of Pyrex® or equivalent. | |

locking mechanism when the cam is turned while | 3. | Close the oven door and turn on the | ||

the door is closed. | ||||

| magnetrons. | |||

|

| |||

For Gen 1 ovens, the right switches (when closed in | 4. | Position the microwave survey meter as shown | ||

conjunction with the primary switch) supply power |

| in Figure 5.4. | ||

to the K3 and K4 relays, which close and distribute | 5. | Measure microwave emission: | ||

power to the right and left | ||||

ers, allowing for microwave operation. |

| a. | Leave the magnetrons on for 60 seconds. | |

For Gen 2 ovens, the door switch circuit starts and |

| b. While the magnetrons are on, measure | ||

|

| microwave emission around the door, | ||

returns on the control board (secondary switch = |

|

| moving the meter sensor at 1 inch/second. | |

|

| As microwave leakage is observed moving | ||

Control voltage leaves the control board to the relay |

|

| the sensor at 1 inch/second, note any meter | |

board for relay operation. |

|

| spike areas that come close to 5mW/cm2 for | |

|

|

| later | |

Measuring RF Leakage for Microwave Safety |

| c. | Replace the water load every 60 seconds | |

|

| until the test is completed. | ||

An RF (microwave) leakage test must be performed |

|

| ||

6. | Once done scanning the entire door, replace the | |||

at the conclusion of the following service tasks: | ||||

| water load. | |||

- Door removal, replacement, and/or adjustment |

| |||

|

|

| ||

- Door gasket removal, replacement, and/or | 7. | Close the oven door. While the magnetrons are | ||

| ||||

adjustment | on, return the meter probe to any “meter spike” | |

- Waveguide removal and /or replacement | ||

areas and allow the probe to remain in the | ||

- Magnetron removal and/or replacement | ||

“spike” area for 15 seconds per area. Note the | ||

- Door skin removal and replacement | ||

highest reading obtained in each area. | ||

| ||

WARNING: If the unit fails the microwave |

| |

leakage test (leakage greater than 5mW/cm2), the |

| |

oven must be taken out of service immediately until |

| |

the defect is corrected. In addition, the CDRH |

| |

Regulation 21 Subpart C, 1002.20 requires that |

| |

leakage readings of over 5mW/cm2 must be reported |

| |

to the manufacturer. |

|

To measure RF leakage,

1.Access the Installer Setup Mode.

a.Press the “Info” key.

b.Select “Oven Setup.”

c.Select “Installer Setup.”

d. Input the password 042259. | Figure 5.3: Water Load Placement |

|