Page

Precautions

Safety Notice

Horsepower RMS Symmetrical Ampheres

Page

Parameters

Change from Main Source to 2nd Source

Sets the off delay timer for the digital output

Table of Contents

Customizing for Your Application

Troubleshooting

Appendix B Options & Kits

Appendix C RS485 Protocol

Getting Assistance from Baldor

Chapter

Page

Identifying the Drive by Model Number

General Information and Ratings

Storage Guidelines

VS1MD Drive Ratings, Model Numbers and Frame Sizes

General Requirements for the Installation Site

Installing the Drive

Minimum Mounting Clearances

Operating Conditions

Drive Dimensions and Weights Frame a

Mounting Dimensions for the VS1MD Drive

Frame Size B 230V/460V 100 95.5 128 120 130

Frame Screw Size Screw Torque

Mounting the Drive

Protecting the Drive from Debris

Model # Frame Watts Loss

Watts Loss Data

Grounding the Drive

Power Wiring

Grounding Guidelines

Grounding Procedure

RFI Filter Grounding

Connecting Peripheral Devices to the VS1MD Drive

Power Terminal Wiring

Power Terminal Wiring

Specifications for Power Terminal Block Wiring

Recommended Fuses and AC Reactors

Recommended Breakers

Reflected Wave Protection

Page

Stop Circuit Requirements

Control Wiring

Motor Start/Stop Precautions

Description

Terminal Wiring Control I/O

Control Terminal Specifications

Source/Sync for Input Control Wiring

Maximum Control Wire Length Recommendations

I/O Wiring Recommendations

Technical Specifications

Display Description

Keypad Components

Key Descriptions

LED Descriptions

About Parameters

Operation Mode

Moving Between Parameter Groups

Procedure Sample Display

How Parameters are Organized

Terminal group Function Group

Changing Between Parameters Within a Group

Using the Jump Code

Modifying the Value of a Parameter

Modifying Parameter Values

Display Group

Monitoring Display Parameters

Reviewing the Fault Status in the Display Group

Resetting the Parameters to Factory Default

Parameter Number

Overview

Parameter Name

LED Display

Display Group Parameters

Displays the present DC bus voltage level

NOn Current Fault Display Range

Software Version Range Default

Basic Program Group Parameters

P0 Jump Code Range30 Default AccessTunable

P30 Motor HP Select Range

P32 Motor Rated Current Range 50 Amps

P37 Frequency Command Range 400 Hz Default AccessTunable

P35 Frequency Low Limit Range P36 Hz Default

P36 Frequency High Limit Range 400 Hz Default

P38 Stop/Start Source Range

P38 Stop/Start Source

P39 Stop Type Range

Default Access

Access Tunable See Also

P40 Frequency Setting Method Range

P41 Accel Time P42 Decel Time Range 000 sec Default

P46 Drive Start/Stop Source Range

AccessTunable See Also

P47 Frequency Setting Mode Range

Terminal Parameters

T0 Jump Code Range 0 Default Access Tunable

= Preset Speed Ramp Bit 10 = Preset Speed Ramp Bit

= Preset Speed Input Bit

14 = Reserved Reserved

Frequency P4A contact P5B contact Run command

Filtering Time Constant for Multi-function input terminal

Range Default Access Tunable See Also T1-t8

Decrease Down

Parameter Preset Speed Preset Speed Input Bit

6000 Sec

Decel

T32 Digital Output MO T33 Relay Output 3A 3C Range

Access Tunable See also T32-t33

T35 Criteria for Analog Input Signal Loss Range

Sets the minimum voltage of the Analog Input V1 input

Sets the minimum current of the Analog 0-20mA I Input

Relay Output Digital Output Bit

T57 Keypad Error Output

T62 Frequency Loss Mode Range

T60 Inverter Number Range Default Access Tunable See Also

T59 Communication protocol select Range

T61 Baud Rate Range

T63 Frequency Loss Wait Time Range

T64 Communication Time Setting Range

T65 Parity/Stop Bit Setting Range

Access Tunable

F1 Forward/Reverse Run Disable

F0 Jump Code Range Default Access Tunable

Function Group 1 Parameters

F2 Accel Pattern F3 Decel Pattern

F10 DC Brake Voltage Range

DC Brake start frequency

DC Brake wait time

F13 DC Brake start time Range

F11 DC Brake Time Range

F12 DC Brake start voltage Range

F27 Torque Boost select Range

F14 Time for magnetizing a motor Range

F20 Jog Frequency Range

F30 V/F Pattern

See Also F27-F29

100 %

F40 Energy Savings Level Range

F39 Output voltage adjustment Range

F50 Electronic thermal select Range Default Access

F53 Motor cooling method

F51 Electronic thermal level for 1 minute Range

F52 Electronic thermal level for continuous Range

F56 Default

Default Access Tunable

F54 Overload Warning Level Range

F55 Overload warning time Range

Parameter Descriptions

F60 Stall prevention level Range

F63 Save Up/down frequency Range Default Access

Parameter Descriptions

Function Group 2 Parameters

H0 Jump Code Range 0 Default Access Tunable

H7 Dwell Frequency Range

120

See also H11-H16

H10 Skip Frequency Enable Range 0 Default

= P41 + P41⋅ H17 + P41⋅ H18 = P42 + P42 ⋅ H17 + P42 ⋅ H18

H19 Phase Loss Protection Range 0 3n Default Access Tunable

H22 Speed Search Select Range 0 Default

H27 Auto Restart Time Range

H26 Auto Restart Attempts Range Default Access

H24 Speed Search P Gain H25 Speed Search I Gain Range

See Also P33, H40

H32 Slip Frequency Range

H34 No Load Motor Current Range

H36 Motor Efficiency Range

H39 Carrier Frequency Select Range

H40 Control Mode Select

H37 Load Inertia Rate Range

H42 Stator Resistance Rs Range

H41 Auto-Tuning Range 0 Default

See also H40, H42, H44

See also H40, H41, H42

H44 Leakage Inductance Lσ Range

H45 Sensorless P Gain H46 Sensorless I Gain Range

H50 PID Feedback Selection Range

Parameter Descriptions

H70 Frequency Reference for Accel/Decel Range 0 Default

H72 Power-On Display Range 0 Default

H71 Accel/Decel Time Scale Range 0 Default Access Tunable

H74 Gain for Motor RPM Display Range

See Also D1, H72

See Also H76

H75 DB Resistor Select Range 0 Default

Dec

H77 Cooling Fan Control Range Default Access

VS1MD

H93 Parameter Initialize Range 0 Default

H91 Parameter Read H92 Parameter Write Range Default

Page

Keypad Frequency Setting

Frequency Mode

Frequency Setting via -10 to +10V Input

T49

Group Code Parameter Name Setting Range Initial Unit

Frequency Setting via -10 to +10 Voltage Input + 0 to 20 mA

Frequency Setting via 0 to 20 mA Input

Frequency Setting via 0 to 10 + 0 to 20 mA Input

Operating Command via RS485 Communication

Frequency Setting via RS 485 Communication

Up/down frequency saved

UP-Down

Wire

PID Control

PID Block Diagram

Auto-tuning

Sensorless Vector Control

Factory default by motor ratings

Following table shows 4 types of Speed search selections

Speed Search

Example Speed search during Instant Power Failure restart

How to Use Self-Diagnostic Function

Self-Diagnostic Function

Parameter Read

Parameter Read/Write

Password for the first time

Password Registration

Parameter Initialization / Lock

Parameter Write

Parameter Lock

Changing password. Current PW 123 New PW

Locking the user-set parameters

Unlocking the user-set parameter

FDT-4 FDT-5

Multi-function Output Terminal MO and Relay 3AC

FDT-2

FDT-1

Parameter Name

FDT-3

Over Voltage Trip Ovt

11.5

Low Voltage Trip Lvt

Command Loss

Inverter Heatsink Overheat OHt

During Operation

Cooling Fan Trip Alarm

Wait Time for Run Signal Input

Fault Output

Control

Setting

Accel/Decel

Control Block Diagram

Keypad or Remote keypad 10 ~ +10 ~ 20 mA

Frequency and Drive Mode Setting

Page

Troubleshooting

Determining Drive Status Using the STP/FLT LED

3A/3B MO

Fault Codes

Automatically Clearing Faults Auto Restart Feature

Manually Clearing Faults

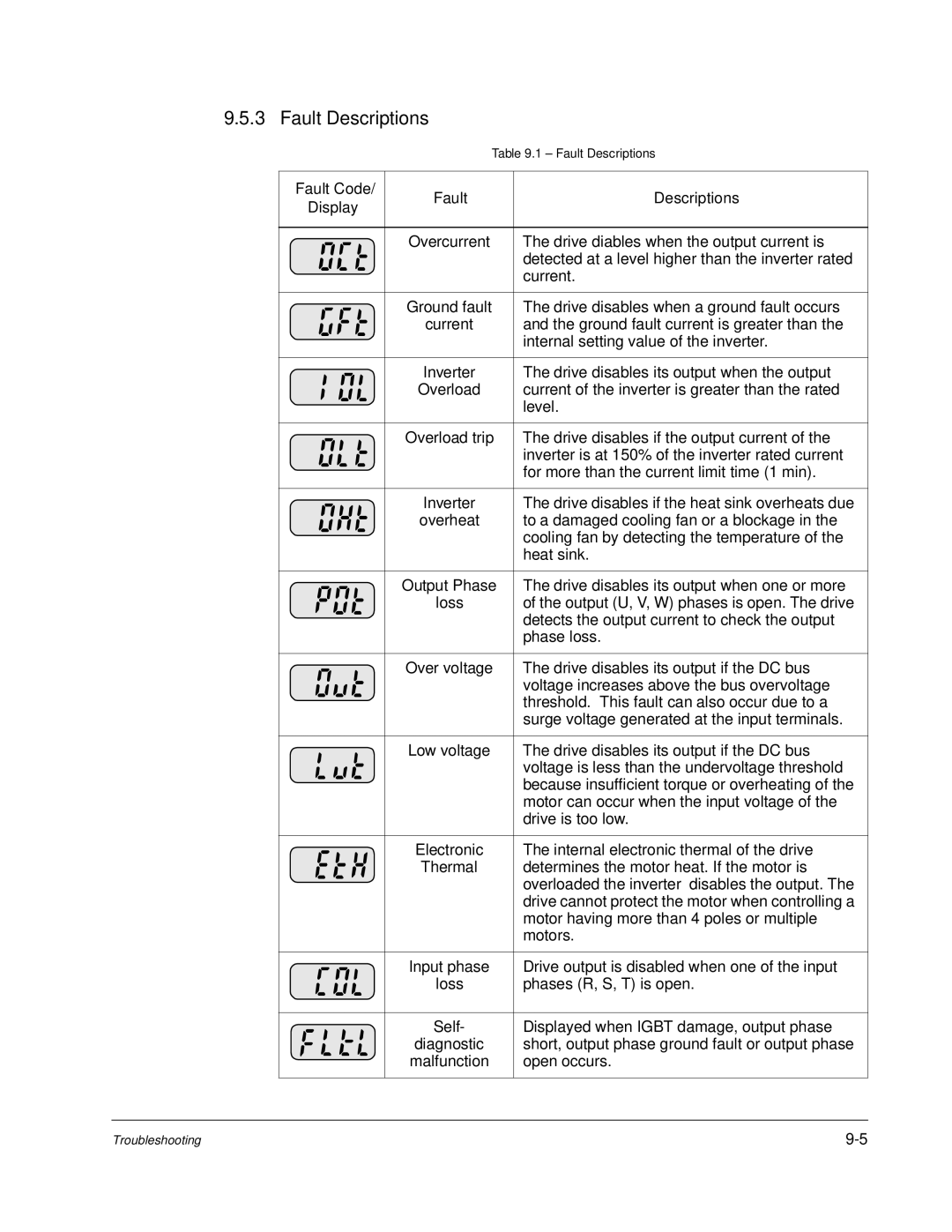

Fault Descriptions

Frequency reference is lost

Fault Correction

Cooling system has Check for foreign

Overload Protection

Page

Terminal Strip Input

Environment

Control

Terminal Strip Outputs

MG, External Power Supply Ground Terminal

Appendix B

Remote Keypad and Cable Model Numbers

Installation

Remote Cable 2M,3M,5M

Options & Kits

3 VS2MD-NM1B

Conduit Kit

Conduit Kit Model Numbers

4 VS1MD-NM1C 5 VS1MD-NM1D

Preparation

Installation refer to legends in diagram

6.2 VS1MD-NM1D Preparation

Conduit Hole Size

Installation

Braking Resistor

Page

Introduction

Features

Before Installation

Performance Specifications

Specifications

Hardware Specifications

Communication Specifications

Connecting the Communication Line

Installation

Operation

Computer and Inverter Connection

Basic Format

Communication Protocol MODBUS-RTU

Communication Protocol LS Bus

ASCII-HEX

Request for Read

Detail Communication Protocol

2.2 Acknowledge Response

2.3 Negative Acknowledge Response

Request for Monitor Register

Negative Response

2.8 Acknowledge Response

2.9 Negative Acknowledge Response

Action Request for Monitor Register

2.13Error codes

2.11Acknowledge Response

2.12Negative Response

Check Points Corrective Measures

Troubleshooting

Miscellaneous

Ascii Code List

Technical Writing Internal Use

DIF

Page