with FOUNDATION Fieldbus Protocol

Reference Manual

Rosemount 2051 Pressure Transmitter

Page

Transmitter with FOUNDATION Fieldbus

Rosemount 2051 Pressure

Rosemount

Reference Manual

Page

SECTION 1 Introduction SECTION 2 Installation

Table of Contents

SECTION 3 Configuration

Rosemount

SECTION 5 Troubleshooting

SECTION Operation and Maintenance

APPENDIX A Reference Data

Rosemount

APPENDIX C Block Information

APPENDIX B Approval Information

Rosemount

Reference Manual

Rosemount

Reference Manual

TOC-4

Section

USING THIS MANUAL SERVICE SUPPORT

Introduction

Rosemount

MODELS COVERED

Rosemount

Reference Manual

OVERVIEW SAFETY MESSAGES Warnings

Installation

Section

Rosemount

CONSIDERATIONS

GENERAL

MECHANICAL

ENVIRONMENTAL

Dimensional Drawings

INSTALLATION PROCEDURES

2051C Coplanar Flange Dimensional Drawing

Rosemount

Rosemount

Coplanar Flange Mounting Configurations with

Reference Manual

00809-0200-4101,Rev AA

2051C Coplanar with Traditional Flange

Rosemount

Reference Manual

Optional Brackets for 2-in.Pipe or Panel Mounting

Traditional Flange Mounting Configurations with

Rosemount

Reference Manual

2051T with Rosemount 306 Integral Manifold

2051T Dimensional Drawings

Rosemount

Reference Manual

Reference Manual

Rosemount

Pipe Mounting

Panel Mounting

2051L Liquid Level

Rosemount

Reference Manual

Mount the Transmitter

Rosemount

Reference Manual

Rosemount

Reference Manual

00809-0200-4101,Rev AA July

Rosemount

Reference Manual

00809-0200-4101,Rev AA July

Rosemount

Reference Manual

00809-0200-4101,Rev AA July

Rosemount

Figure 2-6.Traditional Flange Bolt Configurations

Reference Manual

00809-0200-4101,Rev AA July

Impulse Piping

Rosemount

Reference Manual

Rosemount

Reference Manual

Flow

Process Connections

Rosemount

Reference Manual

Rosemount

Reference Manual

00809-0200-4101,Rev AA July

Housing Rotation

Rosemount

Reference Manual

Tagging

LCD Display

Rosemount

Reference Manual

ELECTRICAL

Conduit Installation

Rosemount

Reference Manual

Wiring

Rosemount

Reference Manual

Transient Protection Terminal Block

Rosemount

Reference Manual

JumpersSecurity

Rosemount

Reference Manual

Grounding

Rosemount

Reference Manual

External Ground Assembly

Figure 2-17.External Ground Assembly

Rosemount

Reference Manual

ROSEMOUNT 305, 306 AND 304 MANIFOLDS

HAZARDOUS LOCATIONS CERTIFICATIONS

Rosemount

Reference Manual

Procedure Rosemount 306 Integral

Rosemount 305 Integral Manifold Installation

Manifold Installation Procedure Rosemount

Conventional Manifold Installation Procedure

Integral Manifold Operation

Rosemount

Reference Manual

Rosemount

Reference Manual

00809-0200-4101,Rev AA July

Open Vessels Closed Vessels

LIQUID LEVEL MEASUREMENT

Rosemount

Reference Manual

Rosemount

Reference Manual

00809-0200-4101,Rev AA July

Rosemount

Reference Manual

00809-0200-4101,Rev AA July

Reference Manual

Rosemount

OVERVIEW SAFETY MESSAGES Warnings

Configuration

Section

Rosemount

Capabilities

DEVICE CAPABILITIES Link Active Scheduler

GENERAL BLOCK INFORMATION Modes

Rosemount

Simulation

RESOURCE BLOCK FEATURES and FEATURES SEL

Rosemount

Reference Manual

MAX_NOTIFY

Rosemount

Reference Manual

ANALOG INPUT AI FUNCTION BLOCK

Configure the AI block

Rosemount

Reference Manual

Configuration Examples

Rosemount

Reference Manual

Rosemount

Reference Manual

00809-0200-4101,Rev AA July

Rosemount

Reference Manual

00809-0200-4101,Rev AA July

Low Cutoff

Filtering

Rosemount

Reference Manual

Status Options

Process Alarms Alarm Priority

Rosemount

Reference Manual

Advanced Features LCD BLOCK

Rosemount

Reference Manual

Rosemount

Reference Manual

00809-0200-4101,Rev AA July

OVERVIEW SAFETY MESSAGES Warnings

Section 4 Operation and Maintenance

Rosemount

Reference Manual

STATUS Master Reset Method Simulation

Rosemount

Reference Manual

Upper and Lower Trim Methods

CALIBRATION Sensor Calibration

Rosemount

Reference Manual

Factory Calibration Method

Sensor Calibration, Zero Trim Method

Rosemount

Reference Manual

OVERVIEW SAFETY MESSAGES Warnings

Section 5 Troubleshooting

Rosemount

Reference Manual

Rosemount

TROUBLESHOOTING GUIDES

Reference Manual

00809-0200-4101,Rev AA July

Rosemount

Figure 5-2.Problems with communications flowchart

Reference Manual

00809-0200-4101,Rev AA July

Rosemount

Table 5-1.Troubleshooting guide

Reference Manual

00809-0200-4101,Rev AA July

RESOURCE BLOCK

Rosemount

Reference Manual

SENSOR TRANSDUCER BLOCK

Rosemount

Reference Manual

Rosemount

LCD TRANSDUCER BLOCK

Reference Manual

ANALOG INPUT AI FUNCTION BLOCK

Rosemount

1.Put Resource block into OOS Out of Service

Reference Manual

00809-0200-4101,Rev AA July

Remove Terminal Block

DISASSEMBLY PROCEDURES Remove from Service

Rosemount

Reference Manual

Remove the Electronics Board

Rosemount

Reference Manual

Electronics Board Install the Terminal Block

REASSEMBLY PROCEDURES Attach the

Reassemble the 2051C Process Flange

Rosemount

Install the Drain/Vent Valve

Rosemount

Reference Manual

Conformance To Specification ±3σ Sigma

PERFORMANCE SPECIFICATIONS

Appendix A

Reference Data

Dynamic Performance

Long Term Stability

Line Pressure Effect per 1000 psi 6,9 MPa

Rosemount

Ambient Temperature Effect per 50F 28C

Vibration Effect Power Supply Effect

Mounting Position Effects

Electromagnetic Compatibility EMC

Service

FUNCTIONAL SPECIFICATIONS Range and Sensor Limits

Protocols

Rosemount

Rosemount

Reference Manual

00809-0200-4101,Rev AA July

Overpressure Limits

Rosemount

Reference Manual

Temperature Limits

Static Pressure Limit Burst Pressure Limits

Rosemount

Reference Manual

Failure Mode Alarm

Humidity Limits Volumetric Displacement Damping

Rosemount

Reference Manual

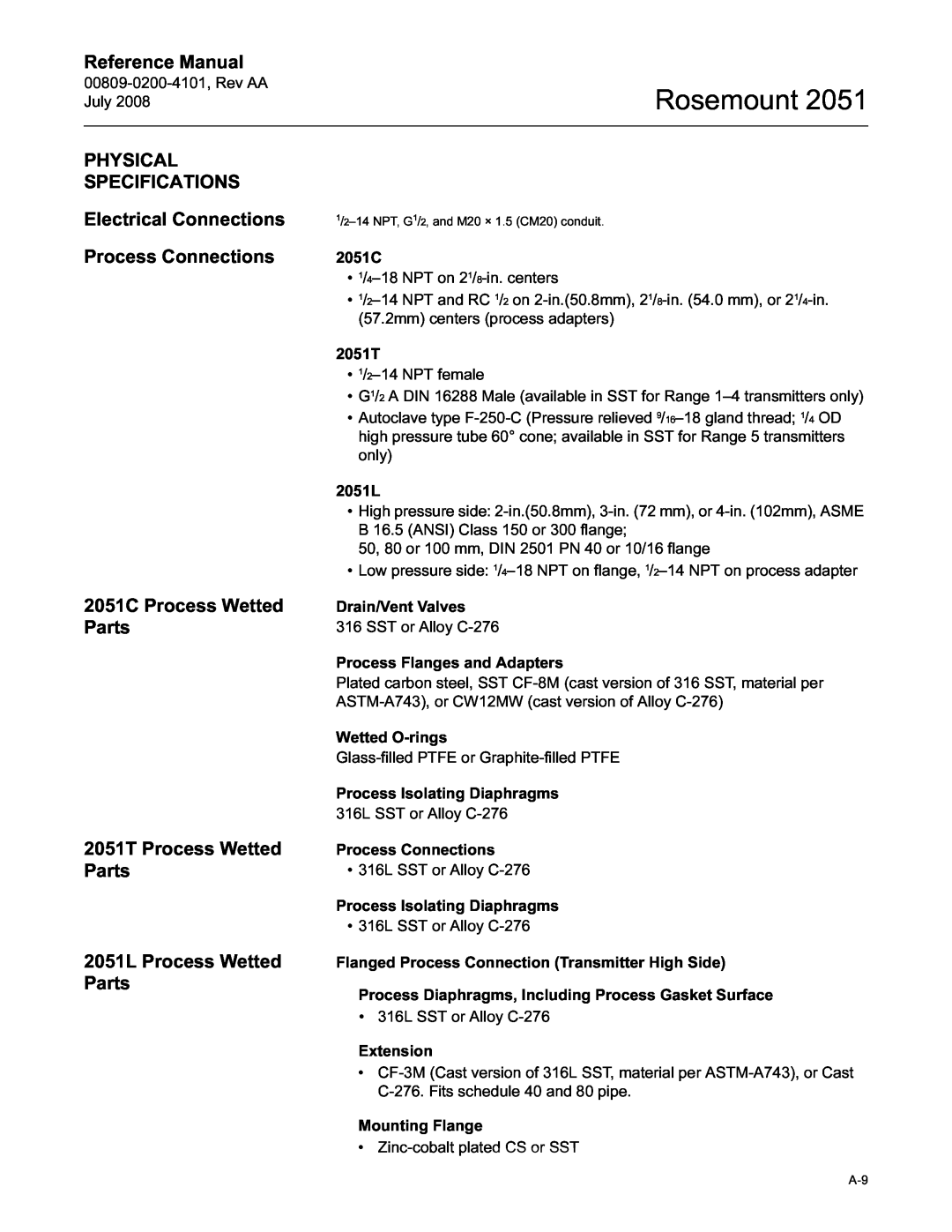

Process Connections 2051C Process Wetted Parts

PHYSICAL SPECIFICATIONS Electrical Connections

2051T Process Wetted Parts

2051L Process Wetted Parts

Non-WettedParts for 2051C/T/L

Rosemount

Reference Manual

Table A-4.Transmitter Weights without Options

Shipping Weights

Table A-5.2051L Weights without Options

Table A-6.Transmitter Options Weights

ORDERING INFORMATION

Rosemount

Reference Manual

Rosemount

Reference Manual

Alternate Process Connection: Flange2

Rosemount

Reference Manual

CSA FISCO Intrinsically Safe

Rosemount

Reference Manual

A-15

Rosemount

Reference Manual

GGage AAbsolute

Rosemount

Reference Manual

FM Intrinsically Safe, Division

Reference Manual

Rosemount

Special Certifications Q4 Calibration Certificate

Prior-usecertificate of FMEDA data

Rosemount

Reference Manual

4 -300to 300 psi/3 psi -20,7to 20,7 bar/0,2 bar

Rosemount

Reference Manual

Syltherm XLT

ATEX Flameproof, Intrinsic Safety, Type n, Dust

Rosemount

Reference Manual

OPTIONS

Rosemount

Reference Manual

Rosemount

Reference Manual

00809-0200-4101,Rev AA July

Rosemount

Reference Manual

00809-0200-4101,Rev AA July

Rosemount

SPARE PARTS

Reference Manual

LCD Display, FOUNDATION fieldbus

Rosemount

Reference Manual

Nickel-platedcarbon steel

Rosemount

Reference Manual

Gage Flange and Adapter Bolt Kit Set of

Rosemount

Reference Manual

A-28

Appendix B Approval Information

OVERVIEW SAFETY MESSAGES

Warnings

Approved Manufacturing Locations

FIELDBUS PROTOCOL

European Directive Information

Hazardous Locations Certifications

Rosemount

Rosemount

Reference Manual

00809-0200-4101,Rev AA July

Rosemount

Reference Manual

00809-0200-4101,Rev AA July

Rosemount

Reference Manual

00809-0200-4101,Rev AA July

Rosemount

Reference Manual

00809-0200-4101,Rev AA July

Rosemount

Reference Manual

00809-0200-4101,Rev AA July

APPROVAL DRAWINGS Factory Mutual FM

Rosemount

Reference Manual

Reference Manual

Rosemount

Rosemount

Reference Manual

B-10

Rosemount

Reference Manual

B-11

Rosemount

Reference Manual

B-12

Rosemount

Reference Manual

B-13

Rosemount

Reference Manual

B-14

Rosemount

Reference Manual

B-15

Rosemount

Reference Manual

B-16

Rosemount

Reference Manual

B-17

Rosemount

Reference Manual

B-18

Rosemount

Reference Manual

B-19

Rosemount

Reference Manual

B-20

Rosemount

Canadian Standards Association CSA

Reference Manual

B-21

Rosemount

Reference Manual

B-22

Rosemount

Reference Manual

B-23

Rosemount

Reference Manual

B-24

Rosemount

Reference Manual

B-25

Rosemount

Reference Manual

B-26

Rosemount

Reference Manual

B-27

Rosemount

Reference Manual

B-28

Rosemount

Reference Manual

B-29

Rosemount

Reference Manual

B-30

Block Information

Appendix C

TRANSDUCER BLOCK Overview

Rosemount

Parameters and Descriptions

Rosemount

Reference Manual

Rosemount

Reference Manual

PRIMARY_VALUE_RANGE

Rosemount

Reference Manual

00809-0200-4101,Rev AA July

Rosemount

Reference Manual

00809-0200-4101,Rev AA July

Overview

Troubleshooting

Rosemount

Reference Manual

Reference Manual

Rosemount

Parameters and Descriptions

00809-0200-4101,Rev AA July

Rosemount

Reference Manual

FLANGE_MTL

Rosemount

Reference Manual

REM_SEAL_FILL

Rosemount

Reference Manual

Simulate_STATE

Rosemount

Block Errors

Reference Manual

00809-0200-4101,Rev AA July

Rosemount

Reference Manual

00809-0200-4101,Rev AA July

Rosemount

Reference Manual

Mode will not leave

Rosemount

Reference Manual

C-14

Index

Rosemount

Reference Manual

Rosemount

Reference Manual

00809-0200-4101,Rev AA July

Rosemount

Reference Manual

00809-0200-4101,Rev AA July

Rosemount

Reference Manual

Index-4

Rosemount

Reference Manual

00809-0200-4101,Rev AA July NOTES

Reference Manual

Rosemount

Page

Rosemount

¢00809-0100-4801V¤

Reference Manual