![]() Outside bearing

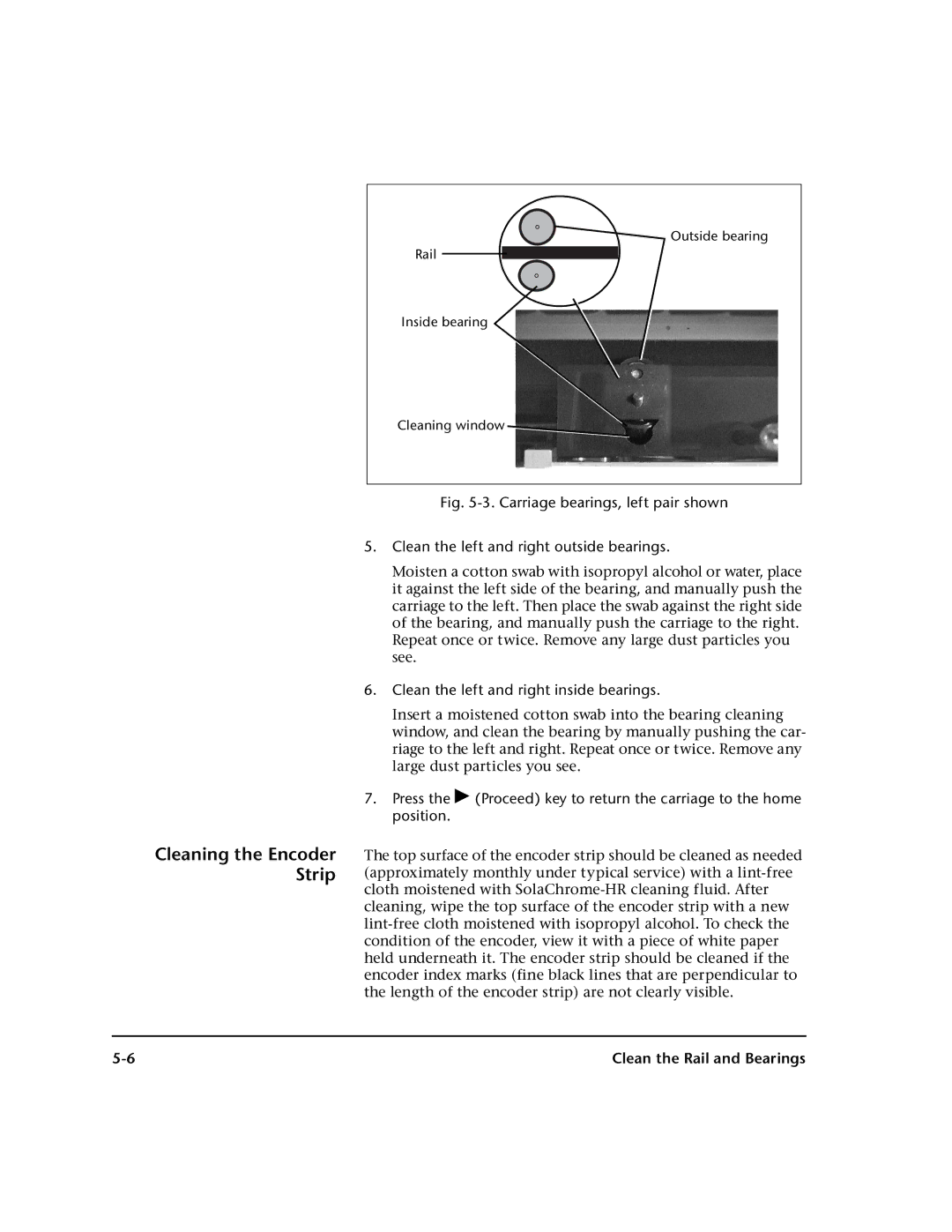

Outside bearing

Rail

Inside bearing

Cleaning window ![]()

Cleaning the Encoder Strip

Fig. 5-3. Carriage bearings, left pair shown

5.Clean the left and right outside bearings.

Moisten a cotton swab with isopropyl alcohol or water, place it against the left side of the bearing, and manually push the carriage to the left. Then place the swab against the right side of the bearing, and manually push the carriage to the right. Repeat once or twice. Remove any large dust particles you see.

6.Clean the left and right inside bearings.

Insert a moistened cotton swab into the bearing cleaning window, and clean the bearing by manually pushing the car- riage to the left and right. Repeat once or twice. Remove any large dust particles you see.

7.Press the ! (Proceed) key to return the carriage to the home position.

The top surface of the encoder strip should be cleaned as needed (approximately monthly under typical service) with a

Clean the Rail and Bearings |