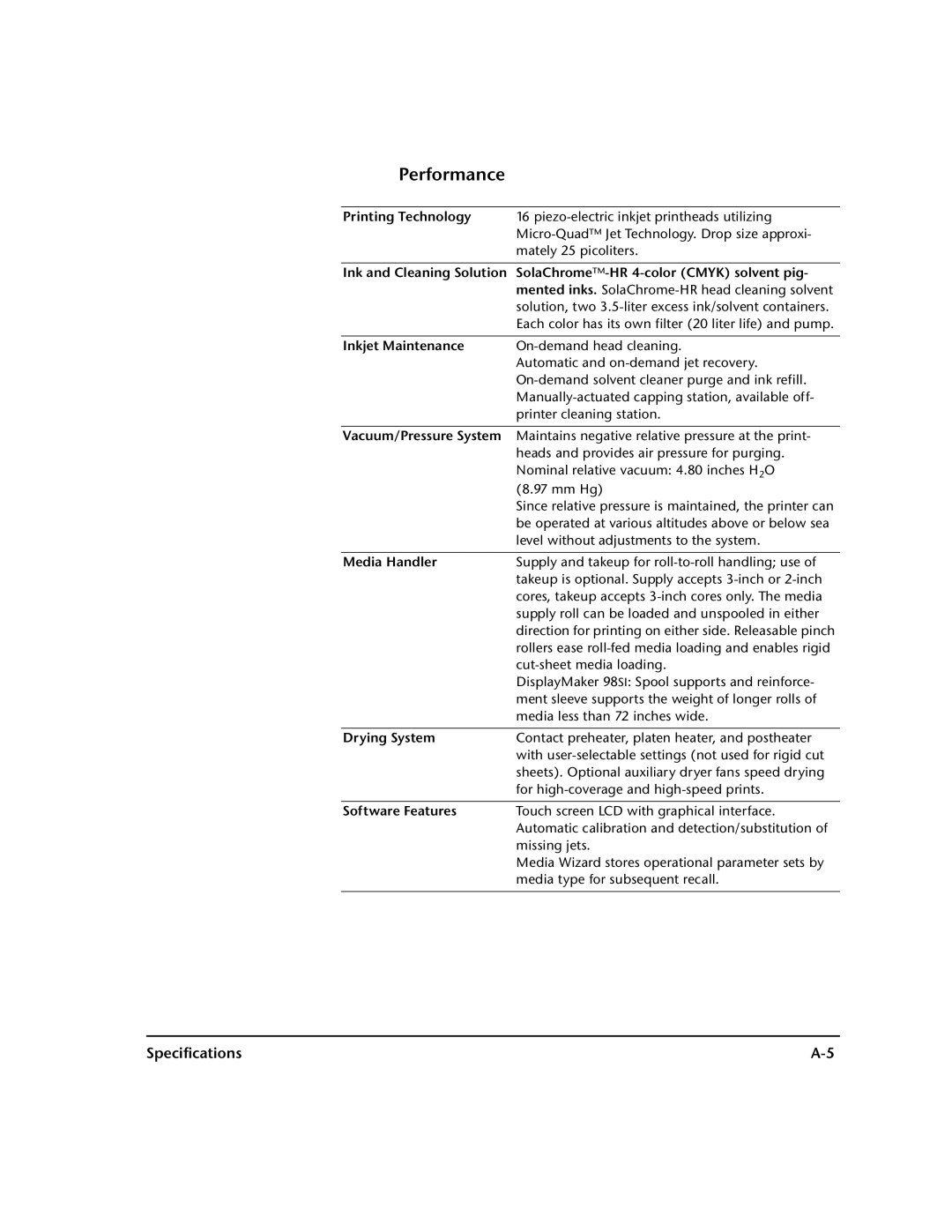

Performance

Printing Technology 16

Ink and Cleaning Solution

Inkjet Maintenance | |

| Automatic and |

| |

| |

| printer cleaning station. |

|

|

Vacuum/Pressure System | Maintains negative relative pressure at the print- |

| heads and provides air pressure for purging. |

| Nominal relative vacuum: 4.80 inches H2O |

| (8.97 mm Hg) |

| Since relative pressure is maintained, the printer can |

| be operated at various altitudes above or below sea |

| level without adjustments to the system. |

|

|

Media Handler | Supply and takeup for |

| takeup is optional. Supply accepts |

| cores, takeup accepts |

| supply roll can be loaded and unspooled in either |

| direction for printing on either side. Releasable pinch |

| rollers ease |

| |

| DisplayMaker 98SI: Spool supports and reinforce- |

| ment sleeve supports the weight of longer rolls of |

| media less than 72 inches wide. |

|

|

Drying System | Contact preheater, platen heater, and postheater |

| with |

| sheets). Optional auxiliary dryer fans speed drying |

| for |

|

|

Software Features | Touch screen LCD with graphical interface. |

| Automatic calibration and detection/substitution of |

| missing jets. |

| Media Wizard stores operational parameter sets by |

| media type for subsequent recall. |

|

|

Specifications |