Return to Section TOC

Return to Master TOC

TROUBLESHOOTING & REPAIR

CAPACITOR REMOVAL AND REPLACEMENT PROCEDURE (continued)

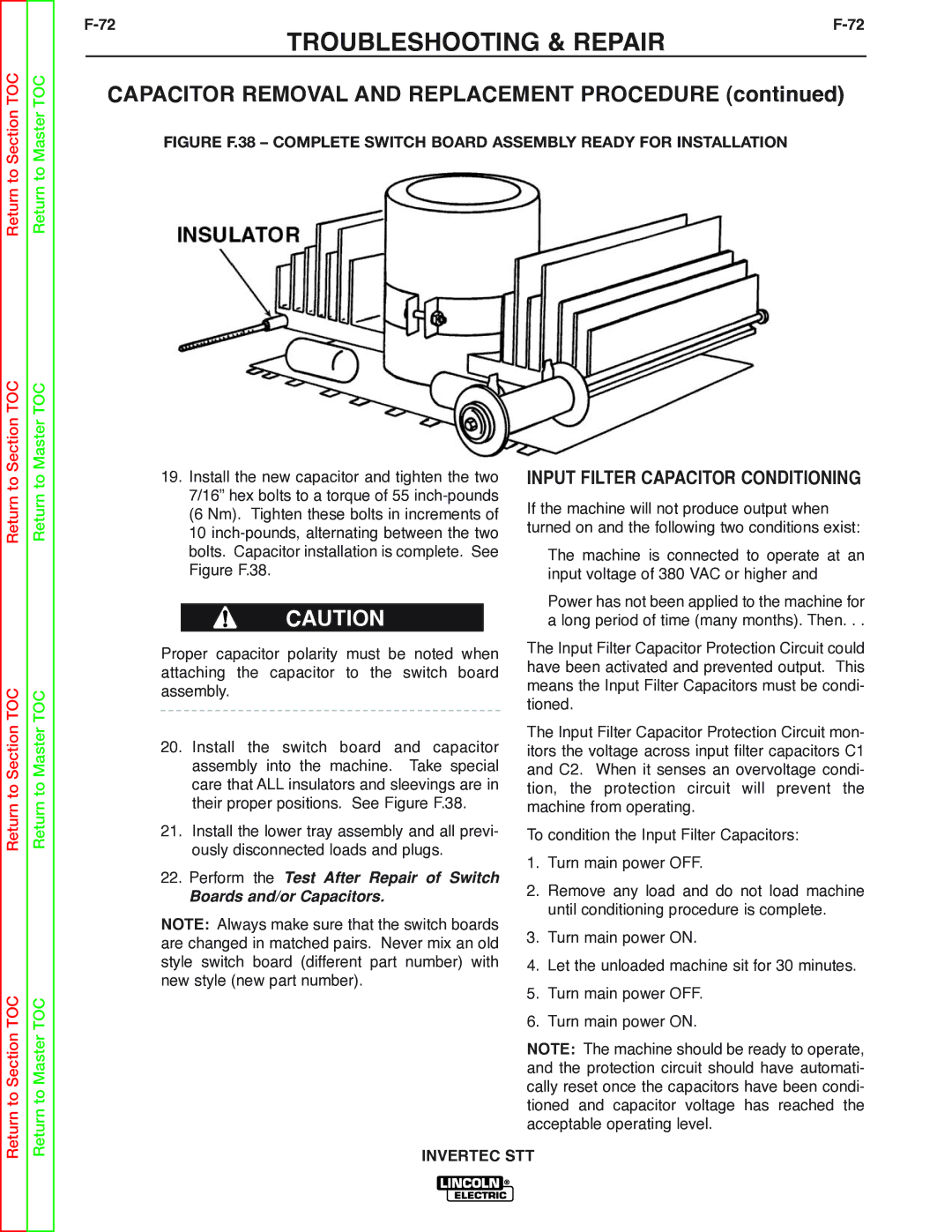

FIGURE F.38 – COMPLETE SWITCH BOARD ASSEMBLY READY FOR INSTALLATION

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

19.Install the new capacitor and tighten the two 7/16” hex bolts to a torque of 55

CAUTION

Proper capacitor polarity must be noted when attaching the capacitor to the switch board assembly.

20.Install the switch board and capacitor assembly into the machine. Take special care that ALL insulators and sleevings are in their proper positions. See Figure F.38.

21.Install the lower tray assembly and all previ- ously disconnected loads and plugs.

22.Perform the Test After Repair of Switch

Boards and/or Capacitors.

NOTE: Always make sure that the switch boards are changed in matched pairs. Never mix an old style switch board (different part number) with new style (new part number).

INPUT FILTER CAPACITOR CONDITIONING

If the machine will not produce output when turned on and the following two conditions exist:

The machine is connected to operate at an input voltage of 380 VAC or higher and

Power has not been applied to the machine for a long period of time (many months). Then. . .

The Input Filter Capacitor Protection Circuit could have been activated and prevented output. This means the Input Filter Capacitors must be condi- tioned.

The Input Filter Capacitor Protection Circuit mon- itors the voltage across input filter capacitors C1 and C2. When it senses an overvoltage condi- tion, the protection circuit will prevent the machine from operating.

To condition the Input Filter Capacitors:

1.Turn main power OFF.

2.Remove any load and do not load machine until conditioning procedure is complete.

3.Turn main power ON.

4.Let the unloaded machine sit for 30 minutes.

5.Turn main power OFF.

6.Turn main power ON.

NOTE: The machine should be ready to operate, and the protection circuit should have automati- cally reset once the capacitors have been condi- tioned and capacitor voltage has reached the acceptable operating level.